Compositions and fabrication methods for hardmetals

A technology for mixtures, superalloys, applied in the direction of carbides, tungsten/molybdenum carbides, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

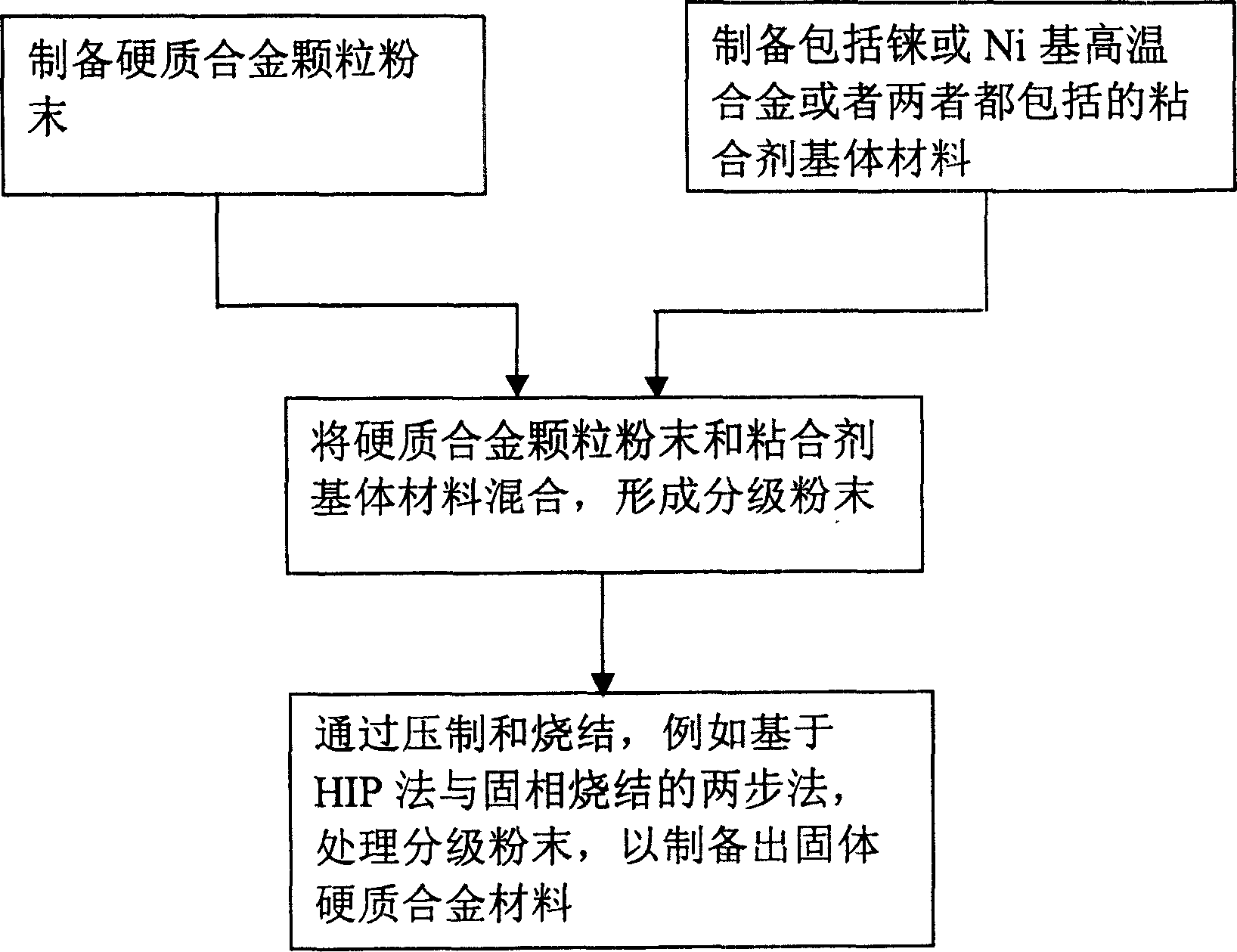

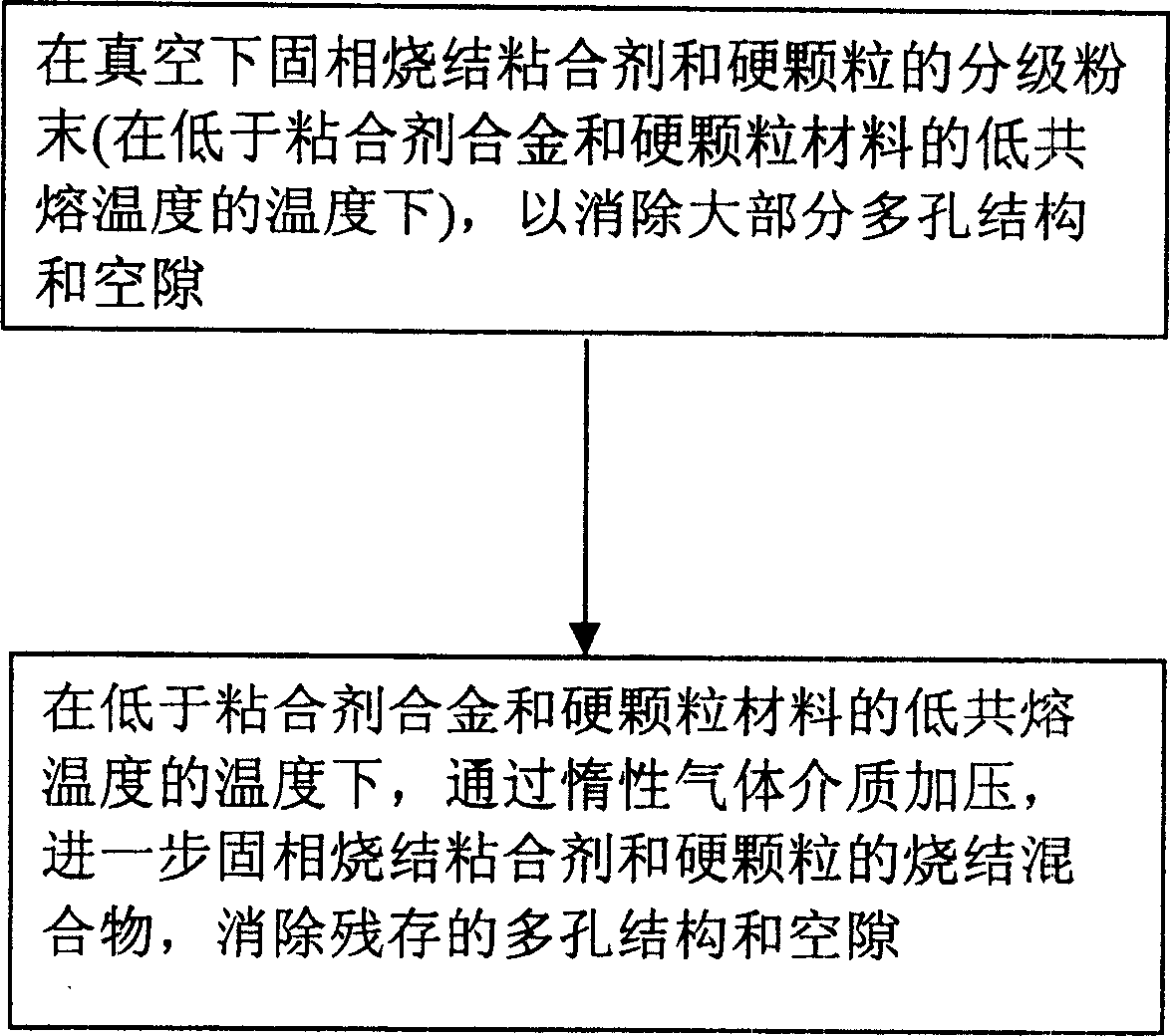

Method used

Image

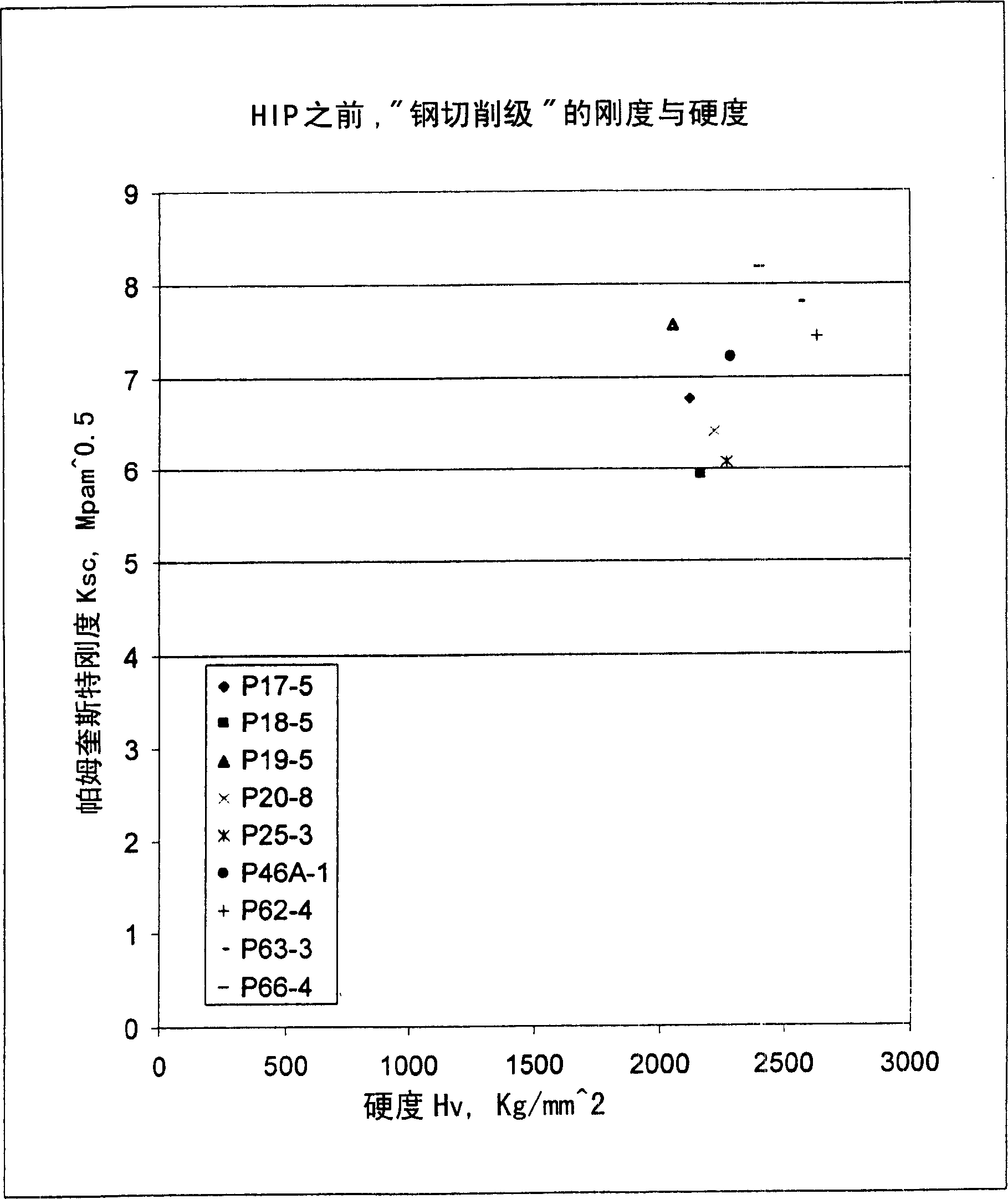

Examples

Embodiment Construction

[0015] The importance of cemented carbide compositions is that they directly affect the technical performance of cemented carbide in its intended application field, as well as the processing conditions and equipment used in the process of preparing such cemented carbide. The cemented carbide composition can also directly affect the cost of the cemented carbide raw material, as well as costs related to the method of preparation. For these reasons and others, the cemented carbide industry has made extensive efforts to develop technically superior and economically useful cemented carbide compositions. Described herein are, among other features, cemented carbide material compositions comprising selected binder matrix materials which together yield performance advantages.

[0016] The material composition of cemented carbides of interest includes: various hard particles and various binder matrix materials. Generally speaking, hard particles can be made of metal carbides of Group I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com