Water spray quantity control system and control method for semi-dry process flue gas desulfurization technology

A desulfurization process and control system technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as unstable operating conditions, easy corrosion of sensors, adhesion of soot, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

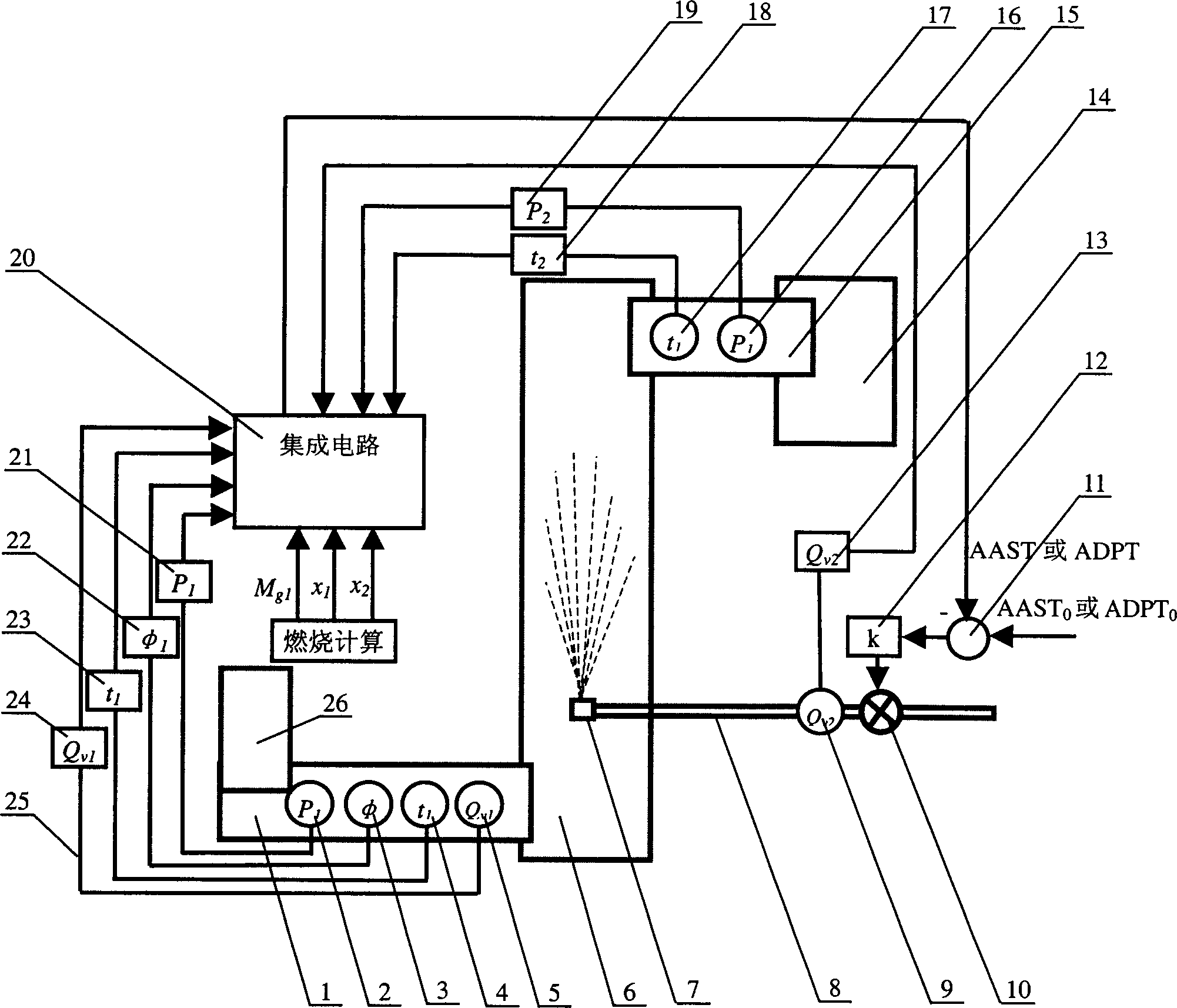

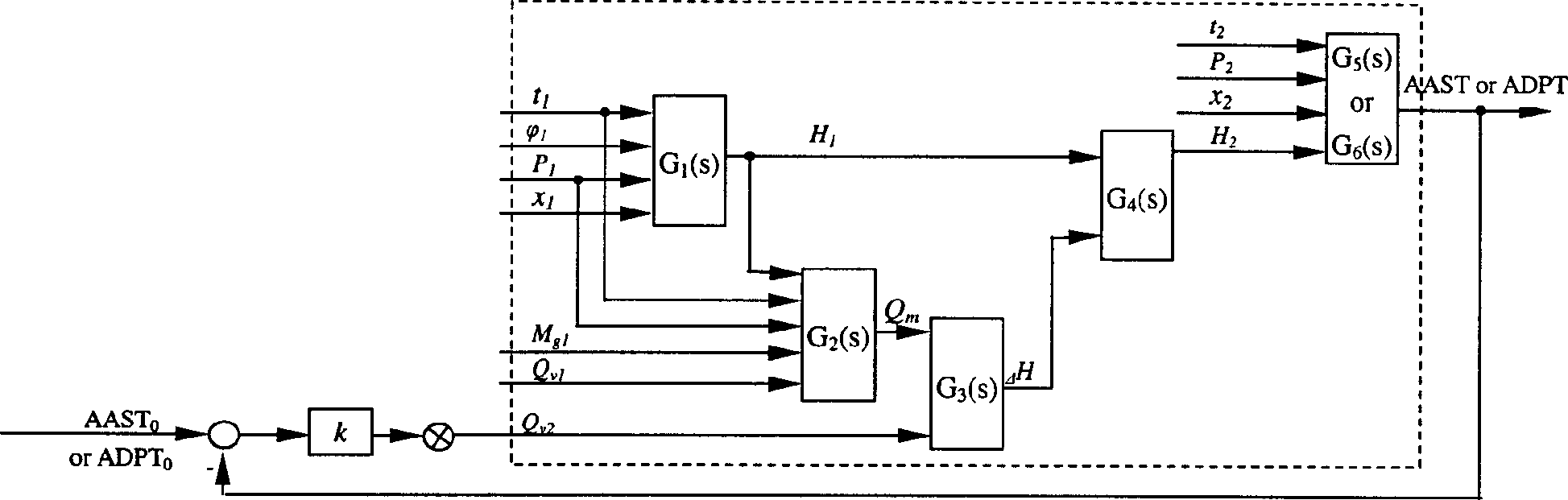

[0121] Structure description: In the interior of the horizontal inlet flue 1 of the desulfurization tower between the air preheater 26 and the main body 6 of the desulfurization tower, the inlet static pressure sensor 2, the relative humidity sensor 3, the inlet temperature sensor 4, and the flue gas volume flow rate are fixedly installed Sensors 5, the signal output terminals of these sensors are respectively connected to the corresponding measuring instruments through signal lines 25: the signal input of the inlet static pressure measuring instrument 21, the relative humidity measuring instrument 22, the inlet temperature measuring instrument 23, and the flue gas volume flow measuring instrument 24 The signal output ends of these measuring instruments are respectively connected to the signal input ends of the corresponding integrated circuits 20 through signal wires 25; Inside, the outlet static pressure sensor 16 and the outlet temperature sensor 17 are fixedly installed, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com