Electric and fuel double groove impeller pump

A technology of fuel oil and grooved vanes, which is applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of further limiting the flow rate of electric fuel impeller pumps, improving, and failing to meet the requirements of output fluid pressure stability, and achieve output pressure stability Good, large flow, reducing friction and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the drawings and embodiments:

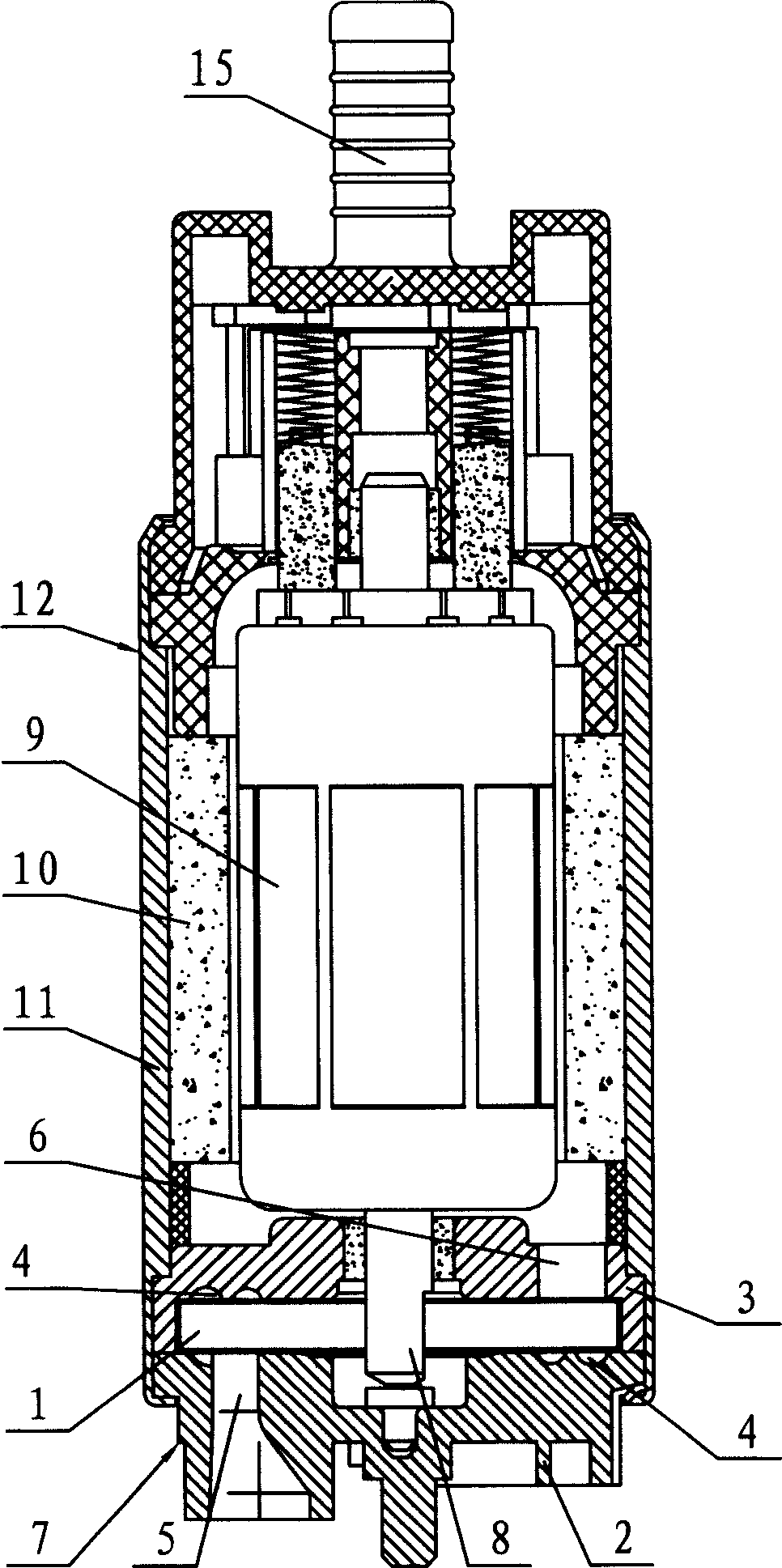

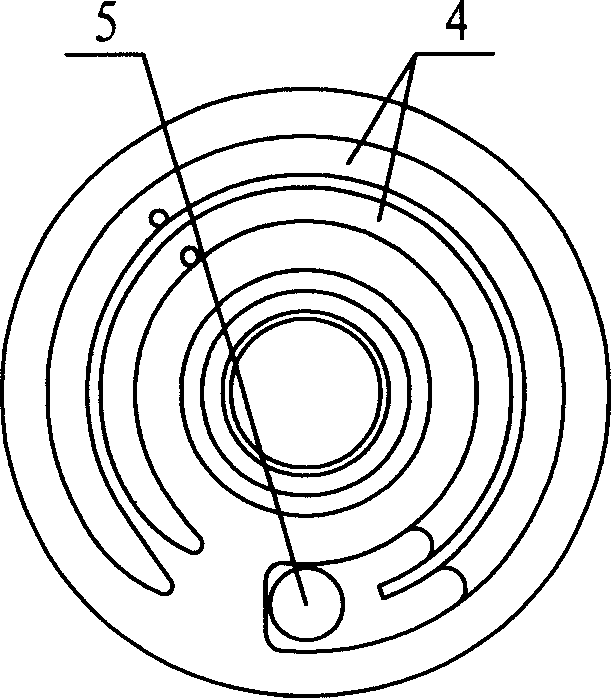

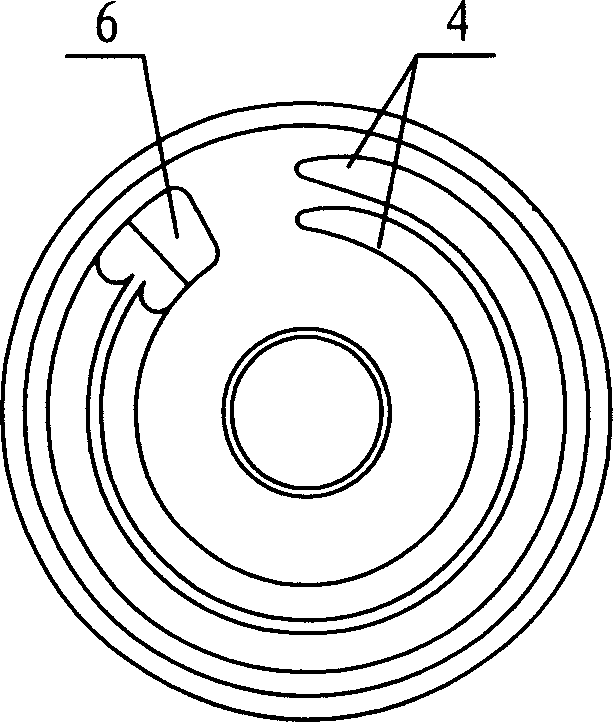

[0013] As shown in the figure, 1 is a disc-shaped impeller with two blades spaced from each other along the outer periphery, and 2 is a pump with a small gap opposite to one side of the impeller 1 and having a sliding surface supporting the impeller 1 The cover 3 is a pump seat with a small gap opposite to the other side of the impeller 1 and has a sliding surface supporting the impeller 1, and 4 is formed on the outer peripheral side of the sliding surface of the pump cover 2 and the pump seat 3 along the impeller 1. Two circular arc belt-shaped pump chambers extending from the two circles of blades, 5 is a fuel suction port provided on the side of the pump cover 2, and 6 is a fuel discharge port provided on the side of the pump seat 3, which is provided with a suction port 5 and the pump cover 2 of the pump chamber 4 and the pump seat 3 provided with the discharge por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com