Single open double seal parallel type gate valve

A parallel gate valve technology, used in sliding valves, valve devices, engine components, etc., can solve the problems of flushing damage to the sealing surface, short service life, high machining accuracy, and achieve good sealing performance, long service life, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

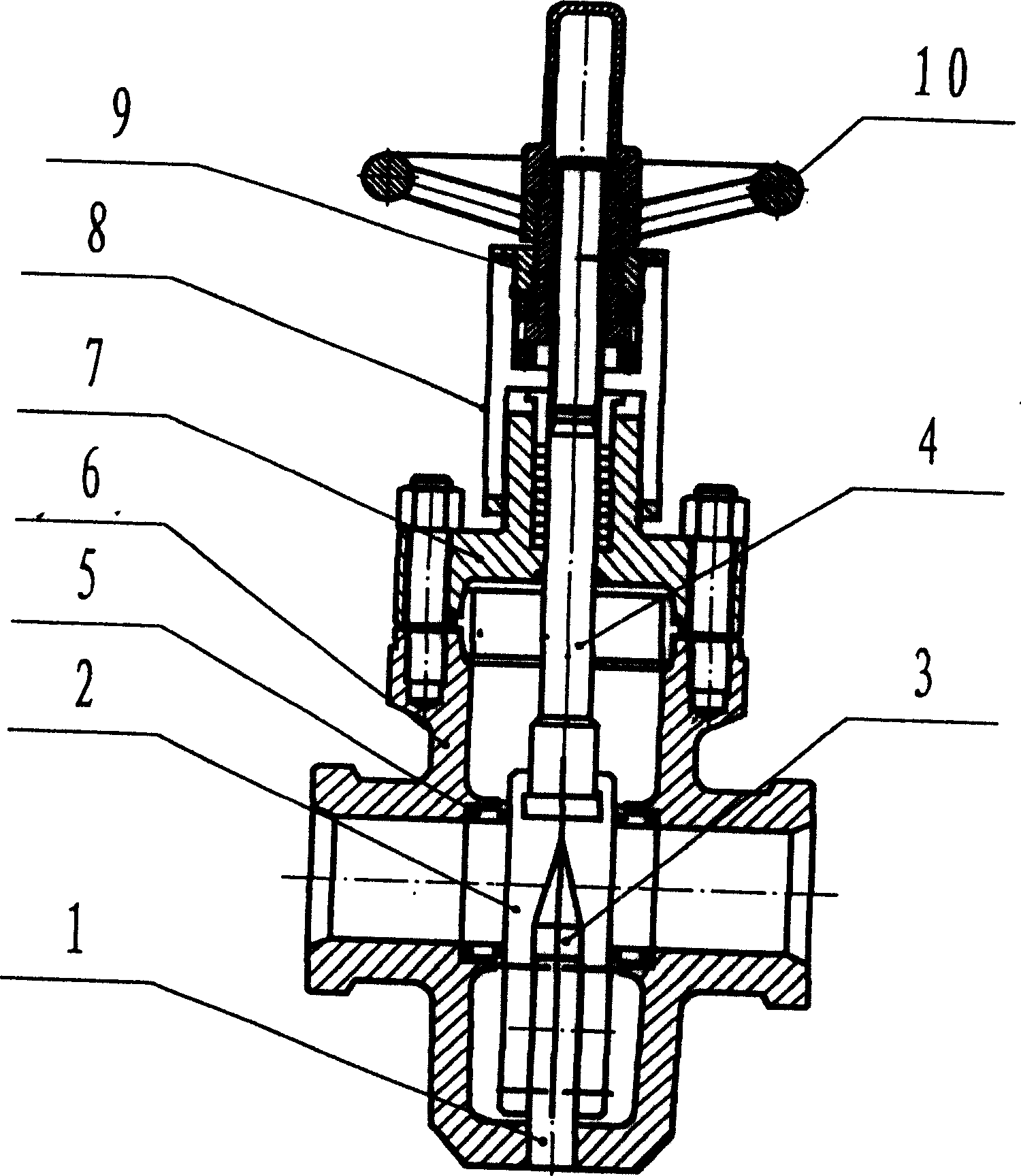

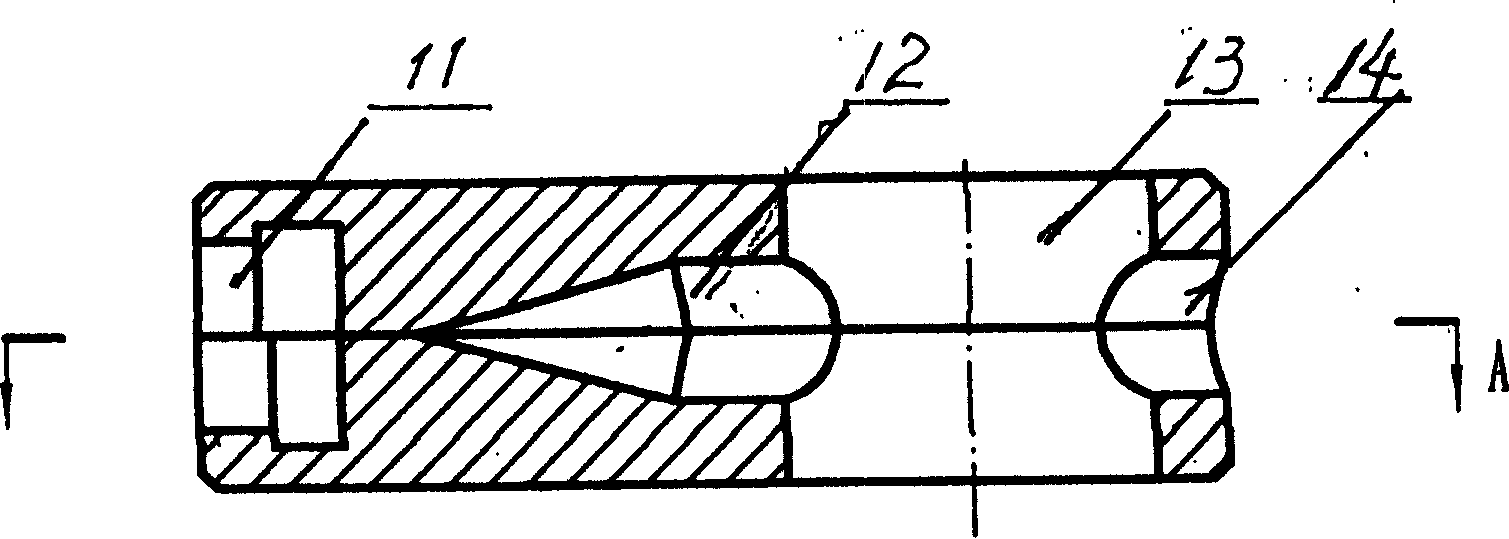

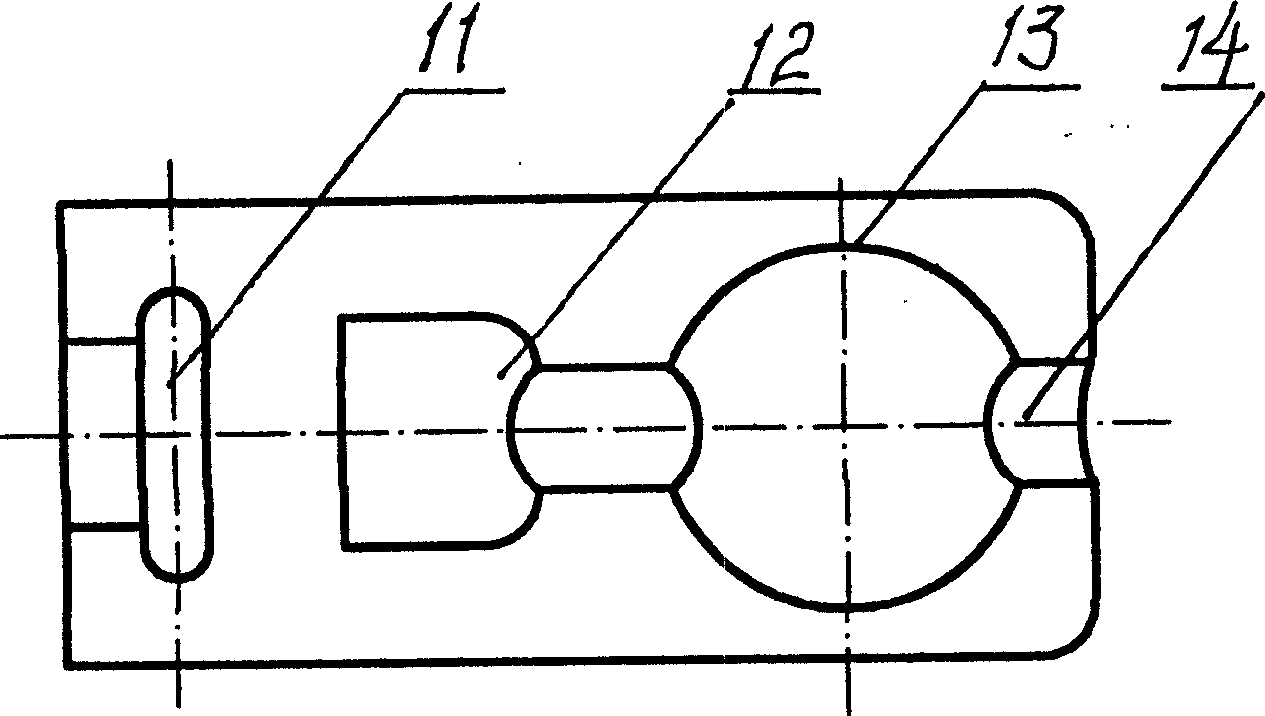

[0016] Concrete technical scheme of the present invention and work process are further described below in conjunction with accompanying drawing:

[0017] figure 1 For the structural situation of the single-opening and double-dense parallel gate valve provided by the present invention, the valve body and the valve benefit are 35CrMo, the valve seat is 1Cr13 and spray-welded with a nickel-based alloy, and the gate is 35CrMo and spray-welded with a cobalt-based alloy, The stem is 2Cr13 and the stem nut is H62 brass. It can be seen from the figure that this kind of single-opening and double-dense parallel gate valve includes a valve body 6, bonnet 7, connecting body 8 and handwheel 10, which are shaped like the upper circle and the lower part of the valve. A valve stem 4 and a gate 2 are arranged in the body cavity, wherein the hand wheel 10 drives the valve stem nut 9, the valve stem nut 9 drives the valve stem 4, and the valve stem 4 drives the gate 2 through a trapezoidal thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com