Process for removing copper of cobalt electrolytic solution

A technology of electrolyte and copper removal agent, which is applied in the field of copper removal, can solve the problems affecting the quality of electrolytic cobalt products, such as the yield of valuable metals, and achieve the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

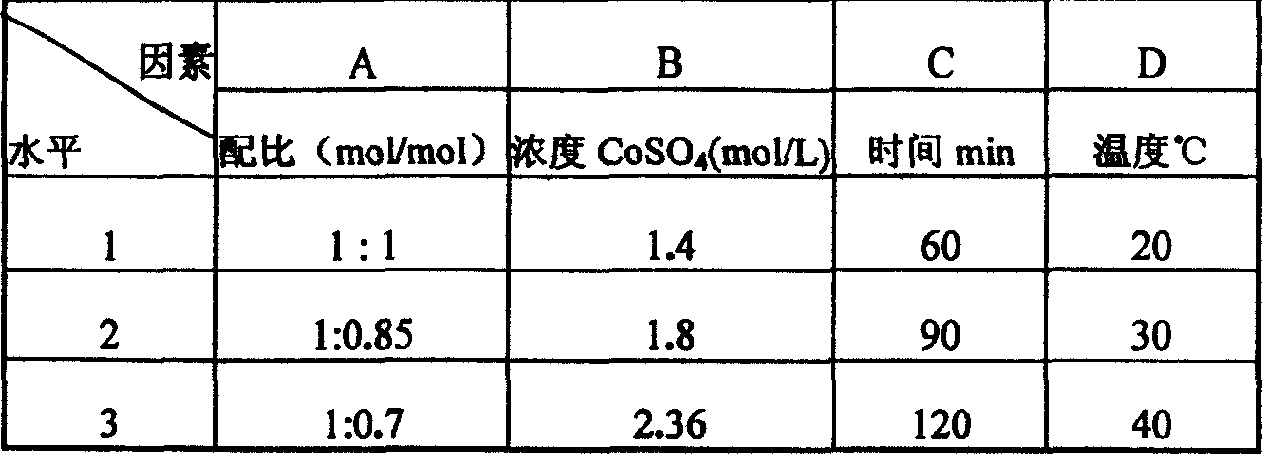

[0039] a Preparation of barium thiosulfate

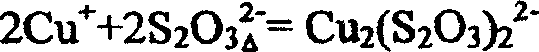

[0040] Searching for BaS by Orthogonal Experimental Method 2 o 3 The best preparation conditions for

[0041] Table 1 Factor level table

[0042]

[0043] Note: ratio refers to NAS 2 o 3· 5H 2 O and BaCl 2 2H 2 The molar ratio of O is known from analysis, scheme C 2 A 2 B 1 for the best. which is:

[0044] ① Proportion 1:1

[0045] ②Temperature 20°C (close to room temperature)

[0046] ③ Stirring time 10min

[0047] In order to obtain relatively pure BaS 2 o 3 , the BaS 2 o 3 Rinse 3 times with hot water at about T≈60°C.

[0048] b Preparation of liquid cobalt thiosulfate copper remover

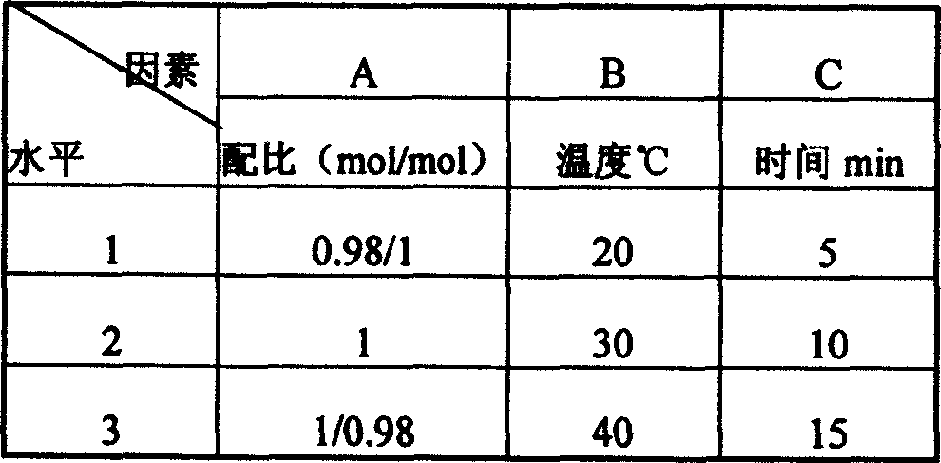

[0049] Using Orthogonal Experiments to Find the Best Preparation Conditions for Liquid Cobalt Thiosulphate Copper Removal Agent

[0050] Table 2 Factor level table

[0051]

[0052] Note: ratio refers to BaS 2 o 3 and CoSO 4 molar ratio

[0053] According to...

Embodiment 2

[0066] First, use sulfuric acid to adjust the value of the iron solution to a predetermined value, measure the solution, put it in a beaker, and place it in an electronic temperature-controlled water bath. And the temperature adjustment controller is preset to a predetermined temperature, and the temperature is raised while stirring slowly. When the temperature of the solution reaches the predetermined value, add an appropriate amount and start timing. After the reaction is completed, filter the solution and analyze the filtrate and residue components.

[0067] (2) Copper removal test with cobalt thiosulfate copper remover

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com