Compacting and plastering machine for concrete surface

A concrete surface and troweling machine technology, which is applied in the direction of construction and building construction, can solve the problems of low work efficiency and footprints, and achieve the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is based on Figure 1 to Figure 10 The specific embodiment of this trowel will be described.

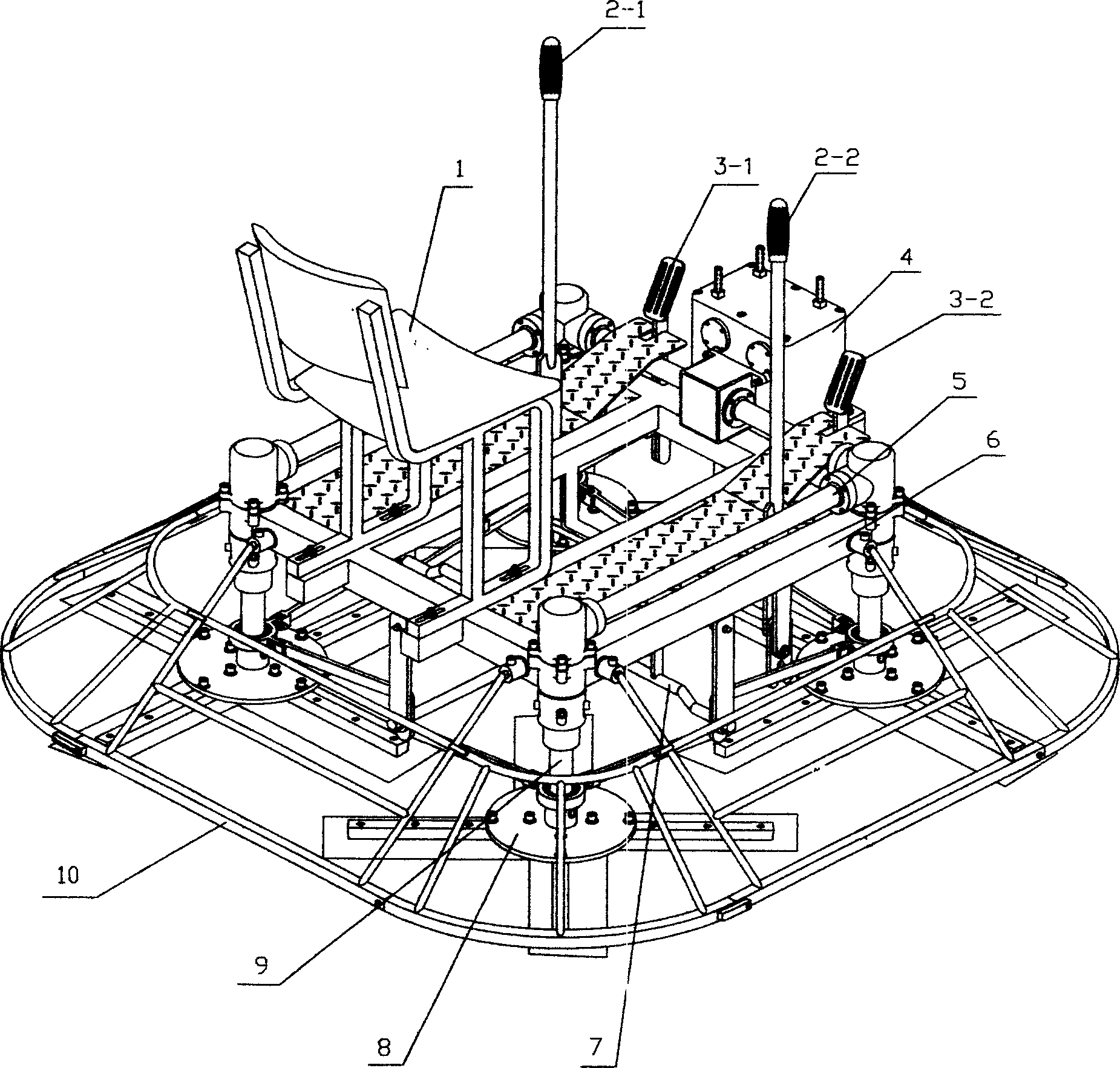

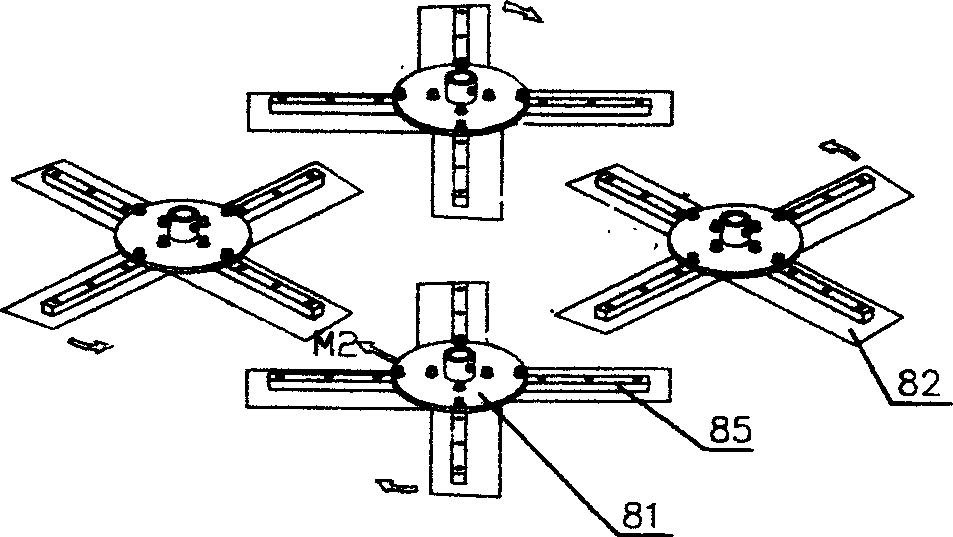

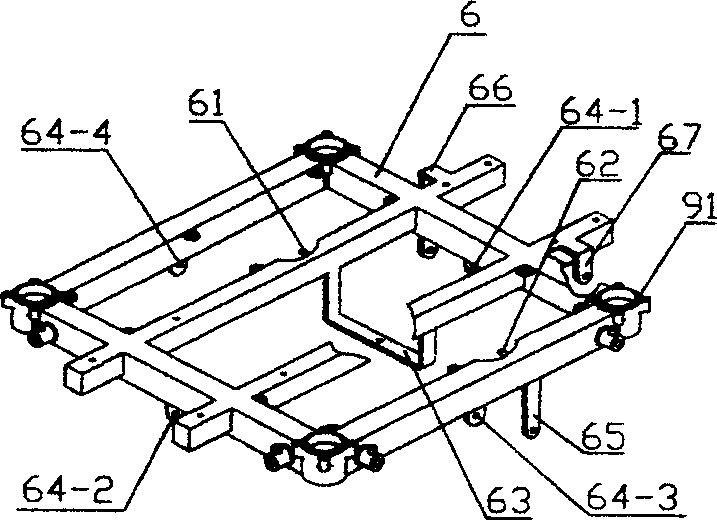

[0024] figure 1 Middle, 1-seat, 2-1-front and rear travel handle, 2-2-steering handle, 3-1-left travel pedal, 3-2-right travel pedal, 4-reducer, 5-power Transmission system, 6-frame, 7-travel linkage mechanism, 8-smearing component, 9-vertical transmission shaft, 10-protective cover, 91-bearing shell; figure 2 Middle, 81-blade fixed base, 82-smoothing blade, 85-blade reinforcing strip; image 3 Among them, 61, 62, 63, 64, 64-1, 64-2, 64-3, 64-4, 65, 66, 67 are respectively the connection points of the corresponding components of the linkage mechanism, which will be explained together with FIG. 8 .

[0025] figure 1 Represent the overall structure embodiment of troweling machine of the present invention, below in conjunction with figure 2 with image 3 right figure 1 Be explained. figure 1 The four groups of wiper components 8 are made up of a blade fixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com