Miniature gas-phase chromatographic chamber

A gas chromatography, micro-miniature technology, applied in the field of gas chromatography, can solve the problems of large volume and weight, poor constant temperature effect, etc., to achieve the effect of reducing the volume of the cavity, reducing the volume, and solving the dead angle of the gas path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

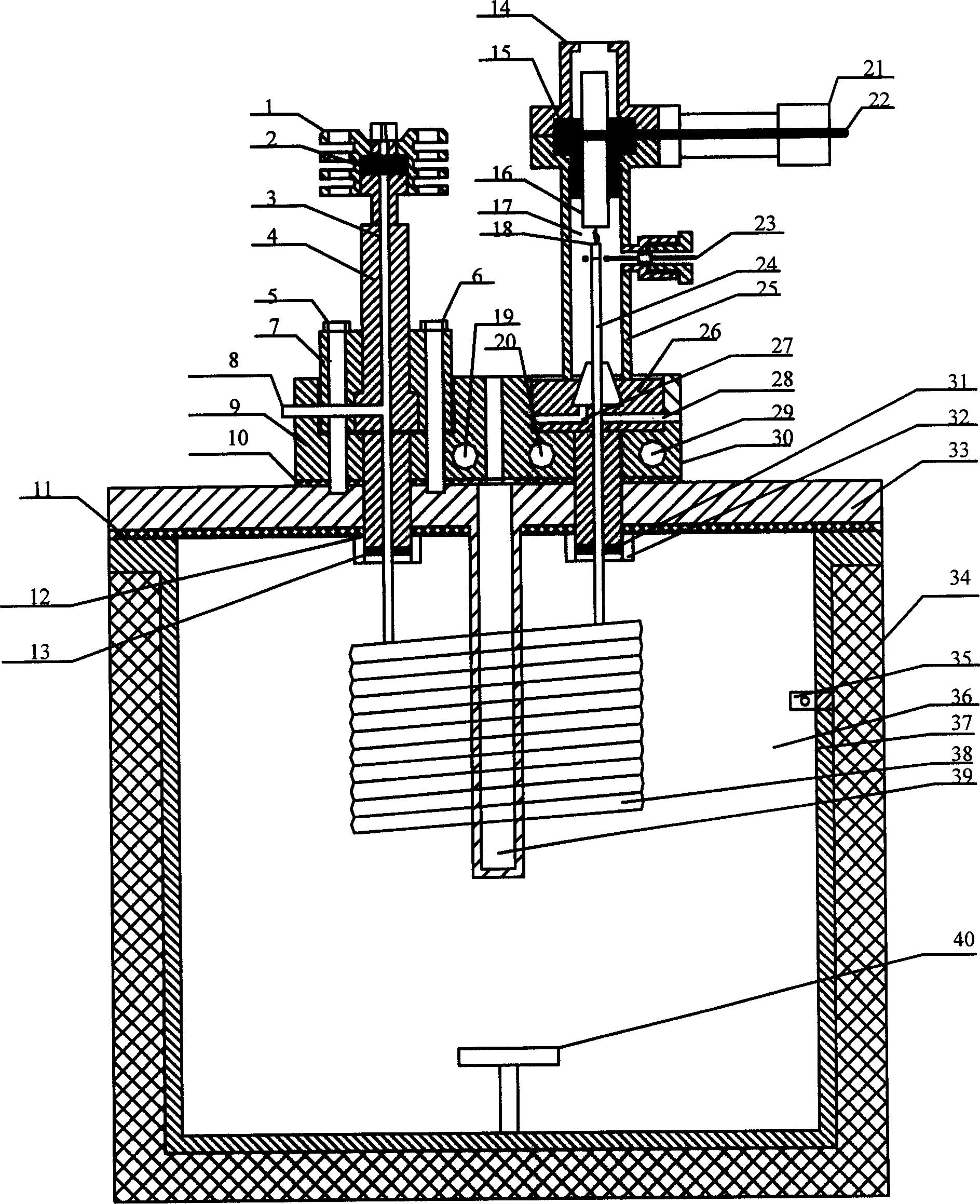

[0020] The chromatographic chamber of the gas chromatograph is composed of three parts: the sampling unit, the separation unit and the detection unit.

[0021] The thermostat block A9, fixed body 7, metal protection body 4, and heat dissipation cap 1 in the sampling unit are connected in sequence, and fixed on the chamber cover 33 of the chromatography chamber through the fixing bolt A5 and the fixing bolt B6, with the heat insulation layer A10 in between. The constant temperature block A9 is provided with a platinum resistance sensor hole A19; the carrier gas inlet 8 passes through the constant temperature block A9 and the fixed body 7, and communicates with the quartz capillary A3 placed in the center of the metal protection body 4; the silicone rubber pad 2 is fixed on the heat dissipation cap 1, and tightly connected with the upper end of the quartz capillary A3.

[0022] The chromatography chamber cavity cover 33 and the chromatography chamber shell 37 in the separation u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com