Vapor phase production of 1,1,1,2,3,3,3-heptafluoropropane from hydrogen fluoride and hexafluoropropylene

A gas-phase, fluorinated catalyst technology, applied in chemical instruments and methods, hydrogen halide addition preparation, organic chemistry, etc., can solve problems such as difficulties in HF recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

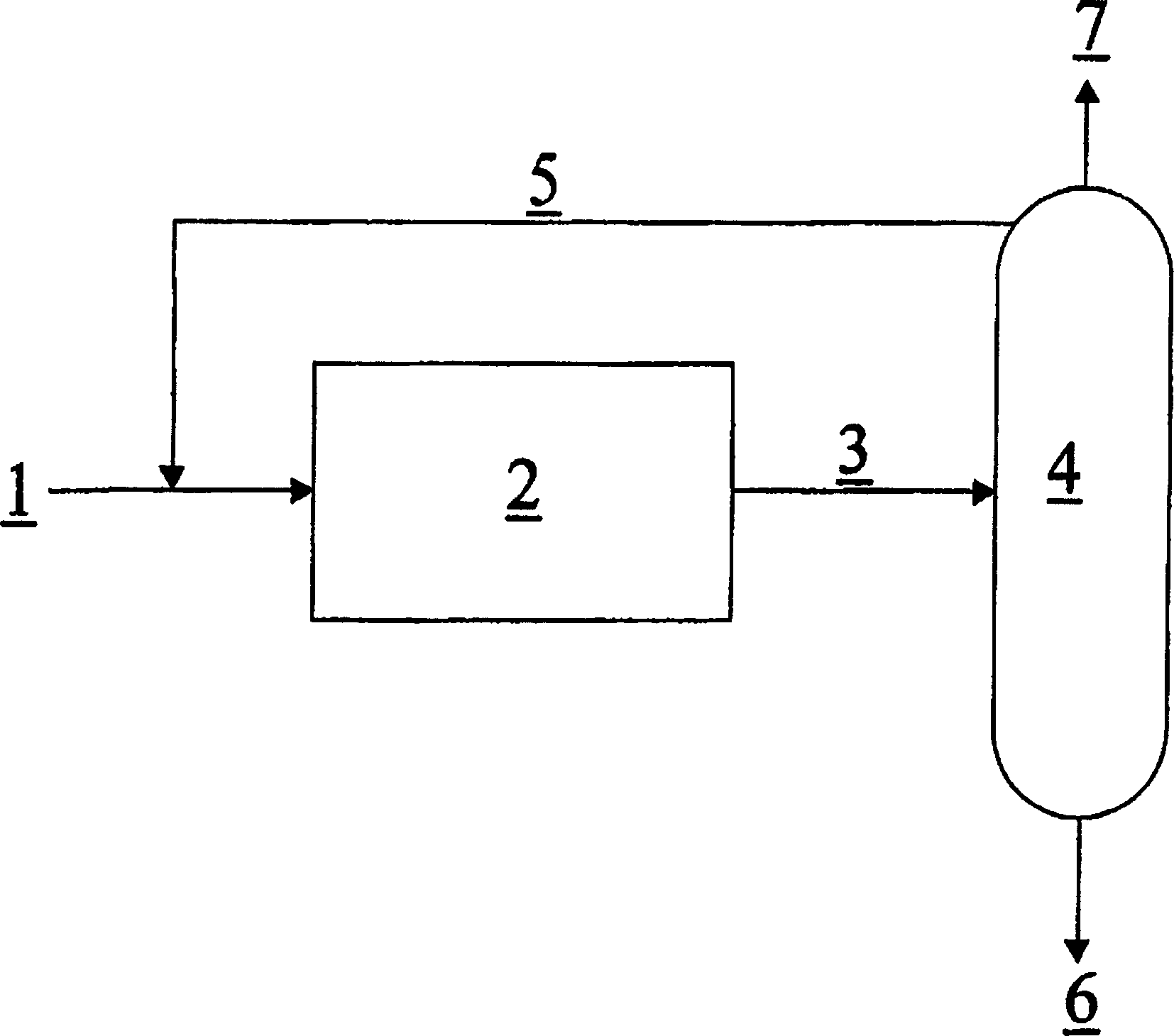

[0026] now refer to figure 1 To further illustrate the present invention, this figure is a simple schematic diagram of a device that can be used to implement the method of the present invention. exist figure 1 In, HF and HFP are vaporized, and then ( 1 ) into a gas phase catalytic reactor operating at 50 psig and 200-300°C ( 2 ). The diluent ( 5 ) into the reactor. into the reactor ( 2 ) molar ratio of HFC-227ea:HF:HFP (by 1 and 5 The mixture of streams obtained) is maintained at approximately 5:3:1 HFC-227ea:HF:HFP. reactor( 2 ) The inlet temperature is maintained at 200°C. By adjusting the diluent flow ( 5 ) flow rate, the entire reactor ( 2 ) was controlled and a high conversion of HFP (95%) was obtained. The reaction mixture containing HF and HFC-227ea was condensed, and ( 3 ) into a distillation column operating at 50-150 psig ( 4 ). HF and HFC-227ea form a low-boiling azeotrope, and substantially all of the HF and the azeotropic amount (or more) of HFC-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com