Substrate delivery in-out device, method and substrate delivery appts. and method

A technology of conveying device and substrate processing device, which is applied in the direction of conveyor objects, transportation and packaging, lighting and heating equipment, etc., which can solve the problems of large-scale clean room and large installation space, and achieve the effect of structural simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

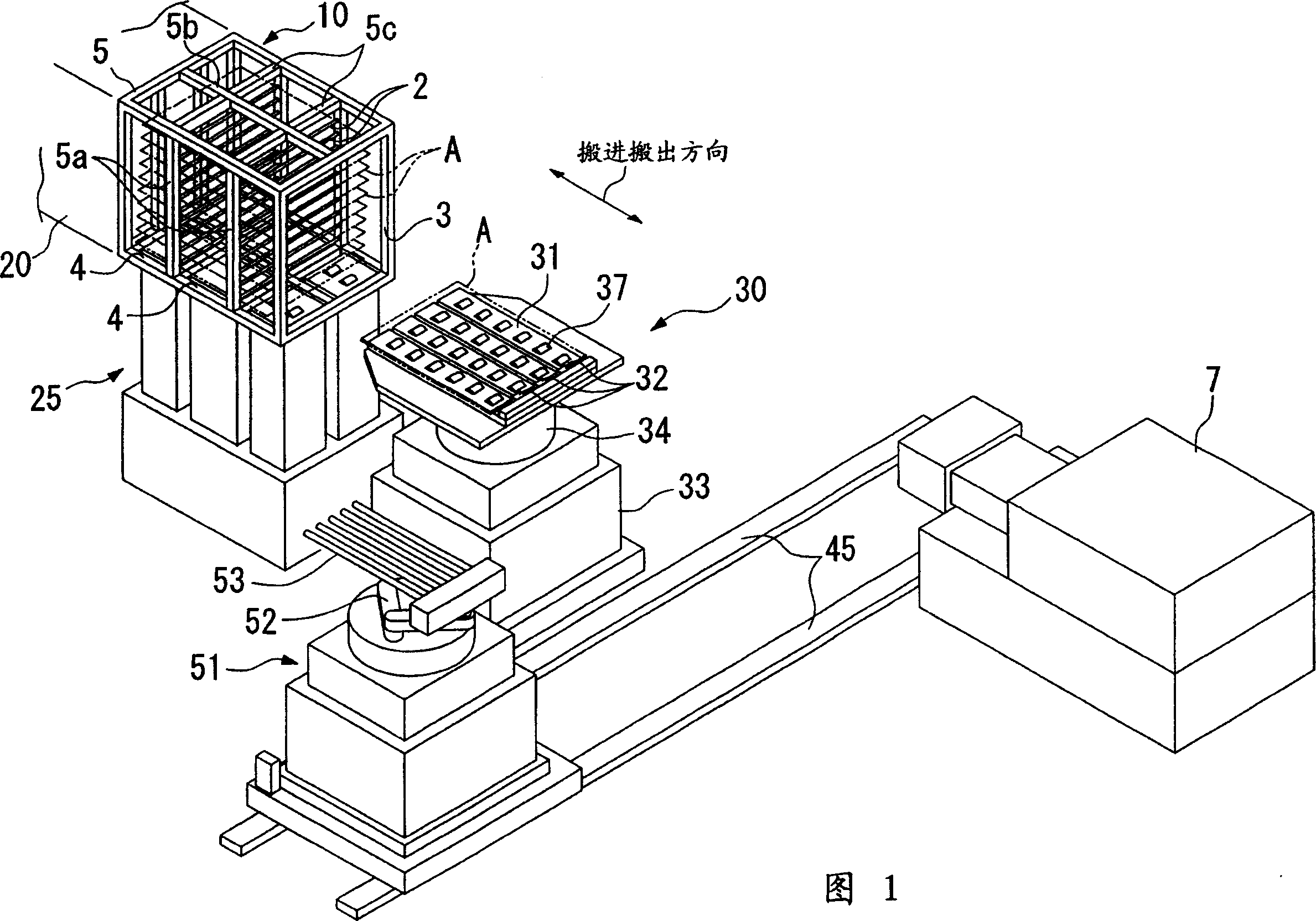

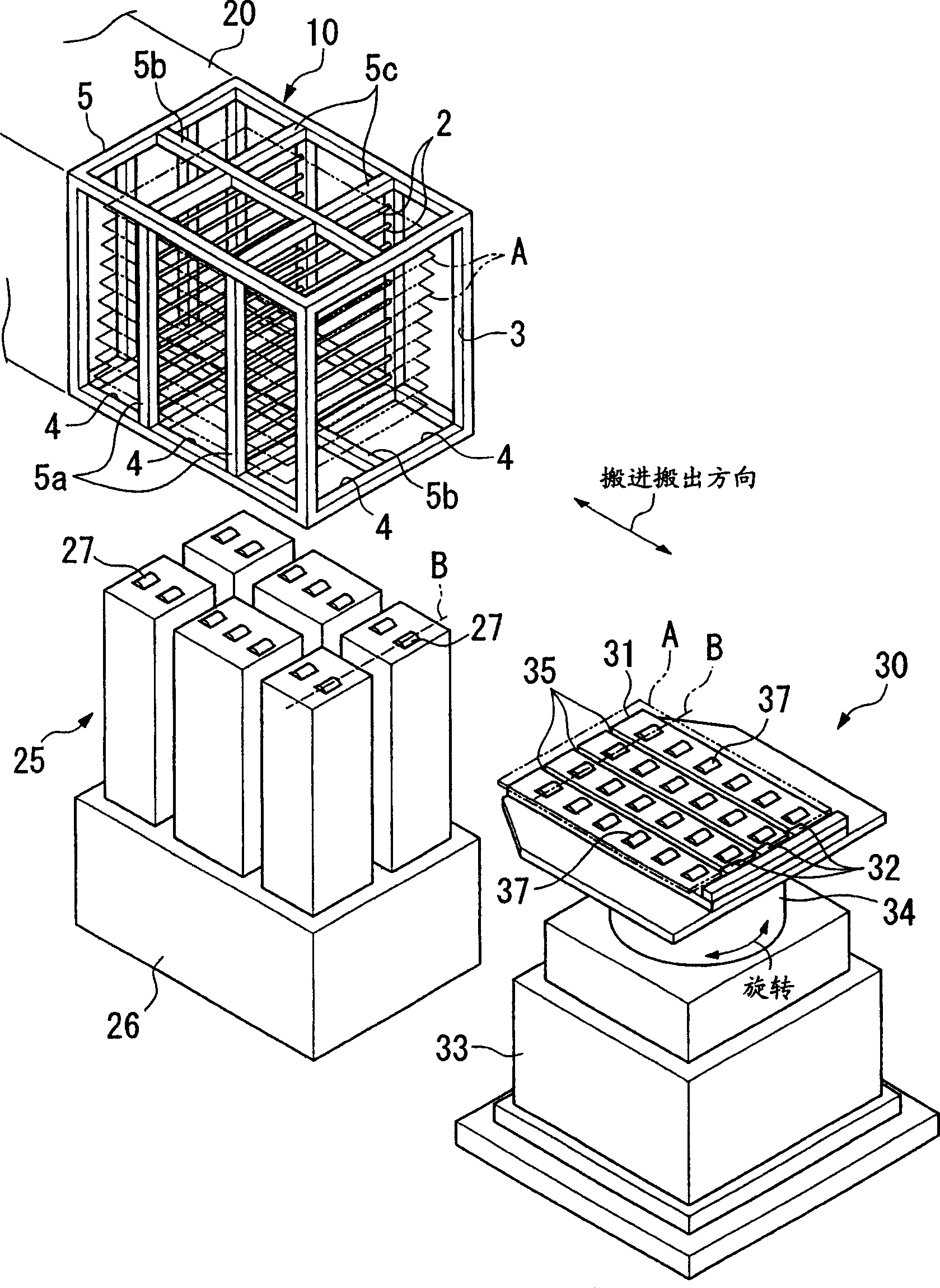

[0070] Below, refer to Figure 1 to Figure 10 A first embodiment of the substrate loading and unloading device of the present invention will be described.

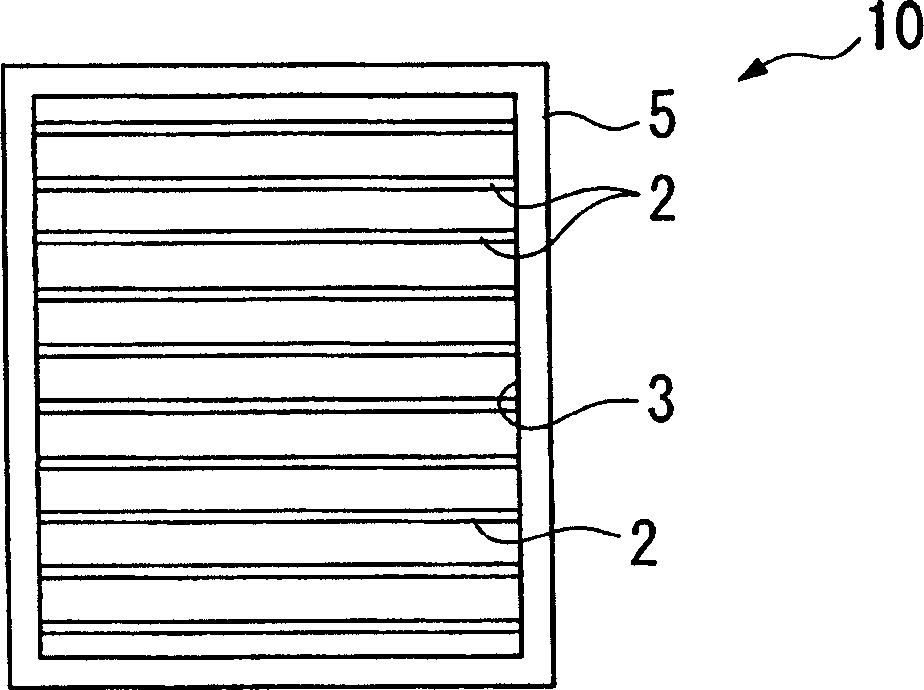

[0071] As shown in FIG. 1 , a substrate loading and unloading device 1 according to this embodiment accesses a substrate A in a wire cage (storage container) 10 storing a plurality of substrates A therein. The wire cage 10 is provided with a plurality of substrate supporting parts 2 provided at intervals in the vertical direction to place the thin plate-shaped substrates A horizontally, and a loading and unloading port provided on the side for loading and unloading the substrate A in the horizontal direction. 3 and the lower opening 4 located at the bottom.

[0072] wire cage 10, such as Figure 2 to Figure 5As shown, a frame 5 made of metal such as aluminum is formed into a box shape, vertical frames 5a are provided on the sides other than the loading and unloading port 3, and shelves arranged in a direction perpendicul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com