Machine of pressing yarn for cheese yarn on cones

A yarn pressing machine and bobbin technology, which is applied in the field of bobbin yarn pressing devices, can solve problems such as poor uniformity of forming density, poor circulation of dyeing liquid, inconsistent density, etc., and achieve strong adaptability, light weight, and strong mobility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

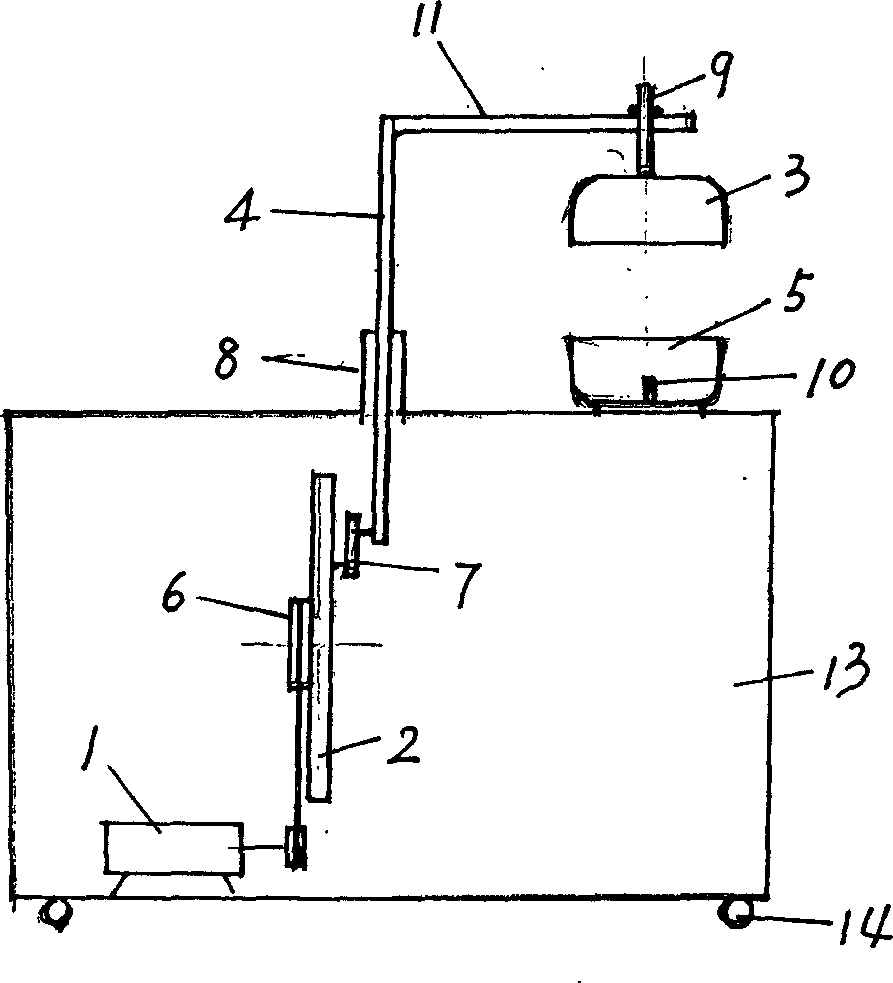

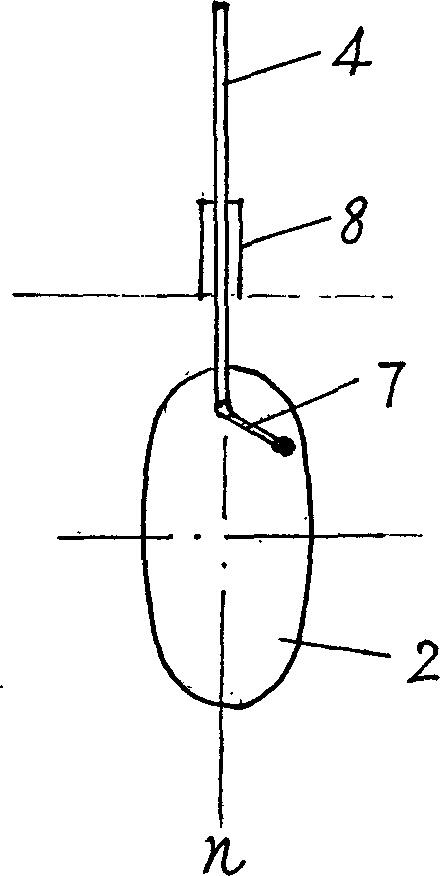

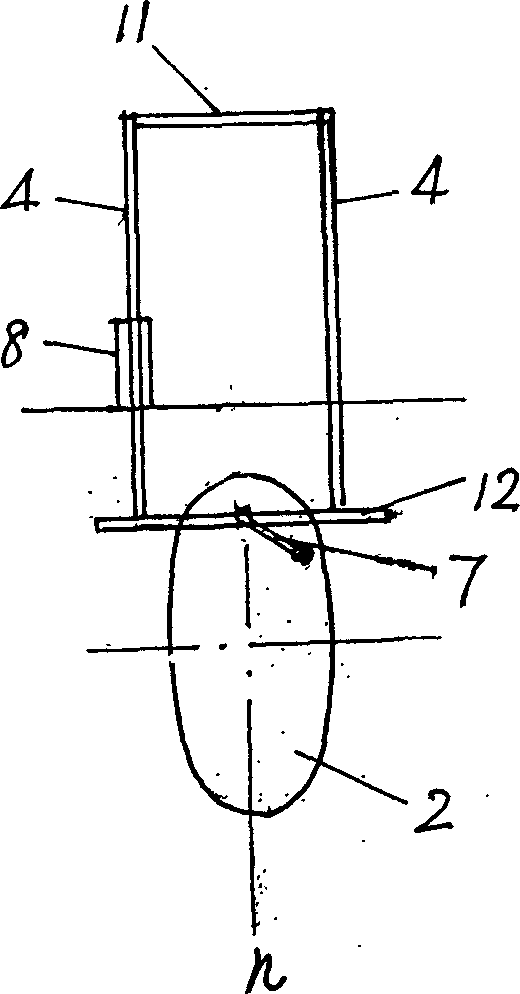

[0022] refer to figure 1 , figure 2 , the bobbin yarn press machine of the present invention mainly comprises motor 1, oval turntable 2, upper pressure pot 3, lifting rod 4, connecting rod 7 and lower pressure pot 5, and one end of connecting rod 7 is fastened on the side of oval turntable 2. On the end face, the other end of the connecting rod 7 is pivotally hinged with one end of the elevating rod 4, for example, a bolt and nut are used to form a pivotally hinged joint. The elevating rod 4 is placed in the guide tube 8 fixed with the workbench, and under the action of the guide tube, the elevating rod is forced to only do lifting motion. When the rotating hinge point connecting the lifting rod 4 and the connecting rod 7 turns to the top of the long axis n of the elliptical turntable, the lifting rod rises to the highest point, and when the rotating hinge point connecting the lifting rod 4 and the connecting rod 7 turns to the oval turning When the major axis n is at the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com