Super-large volume loading voltage regulation autotransformer

A voltage regulating transformer and capacity technology, applied in the direction of transformers, variable transformers, variable inductors, etc., can solve the problems of low product quality qualification rate, high oscillation potential of voltage regulating coil, high production cost, etc., and reach the voltage adjustment range wide, low oscillation potential, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

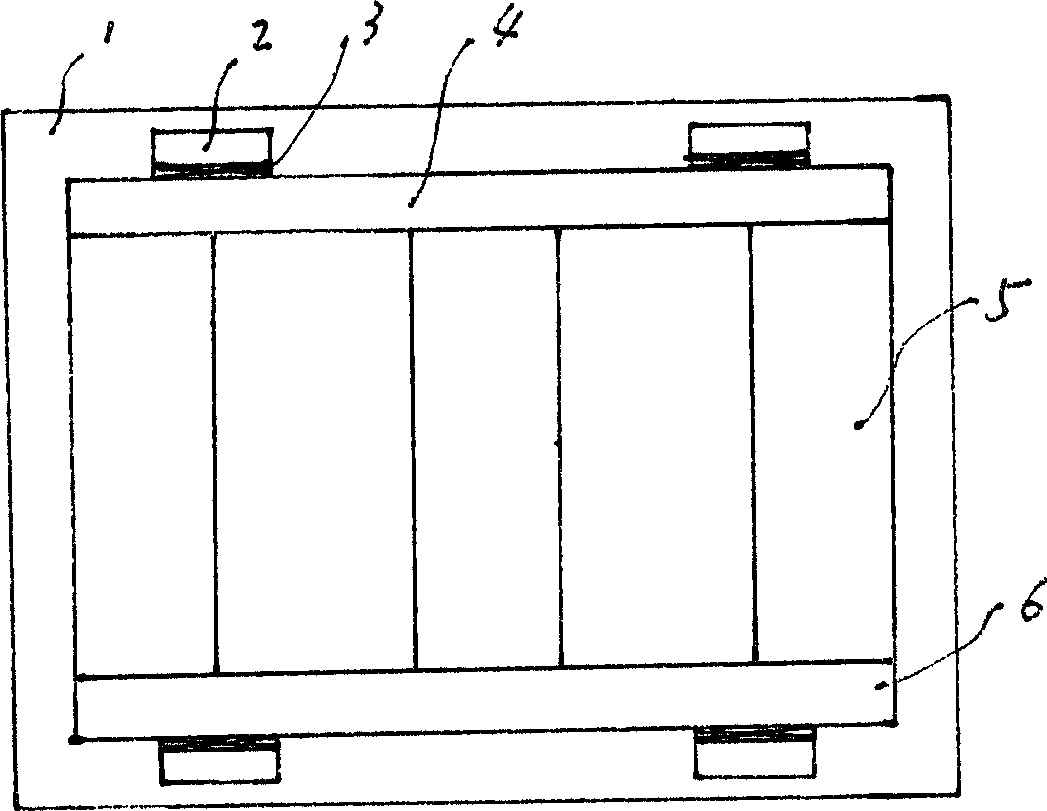

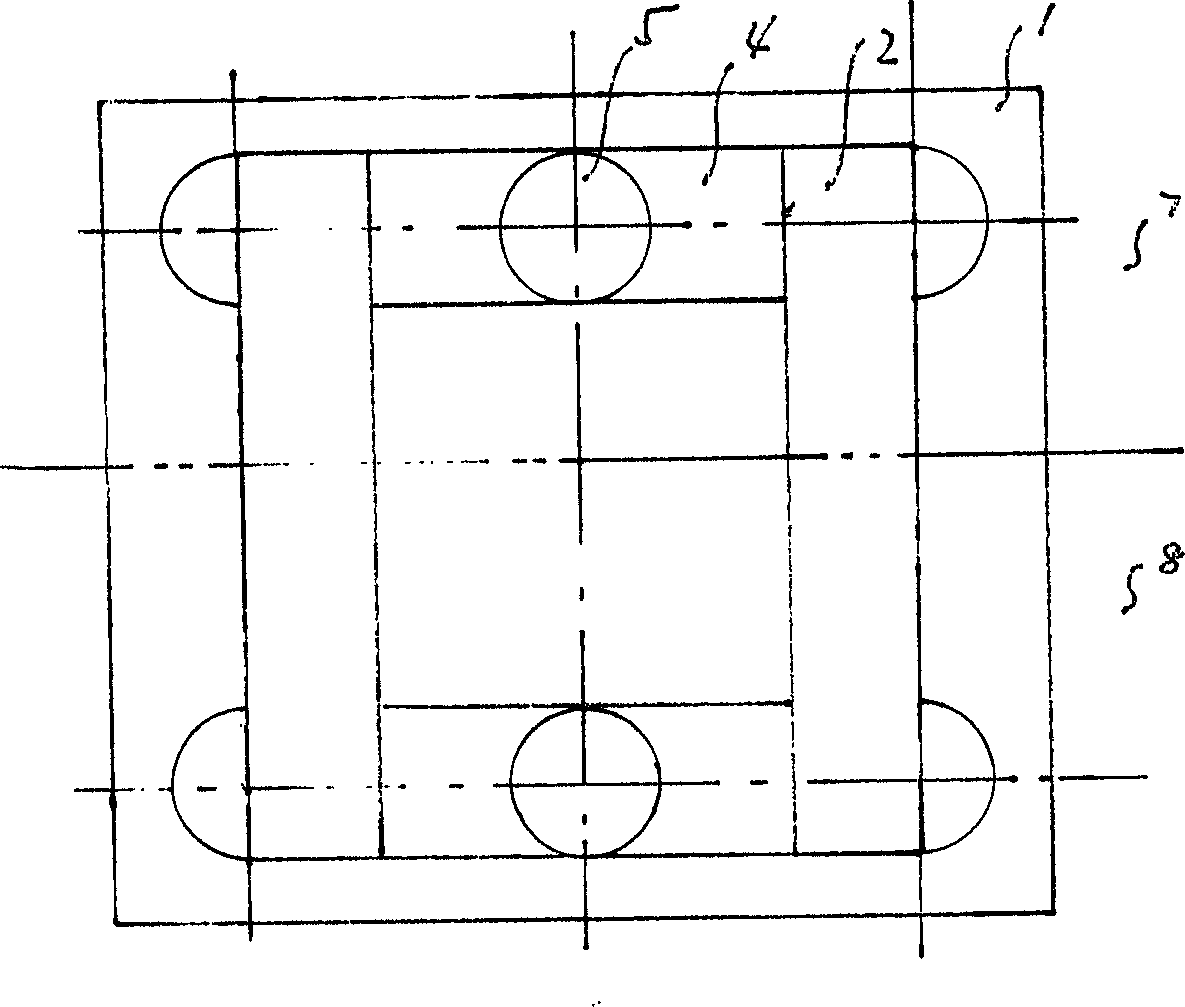

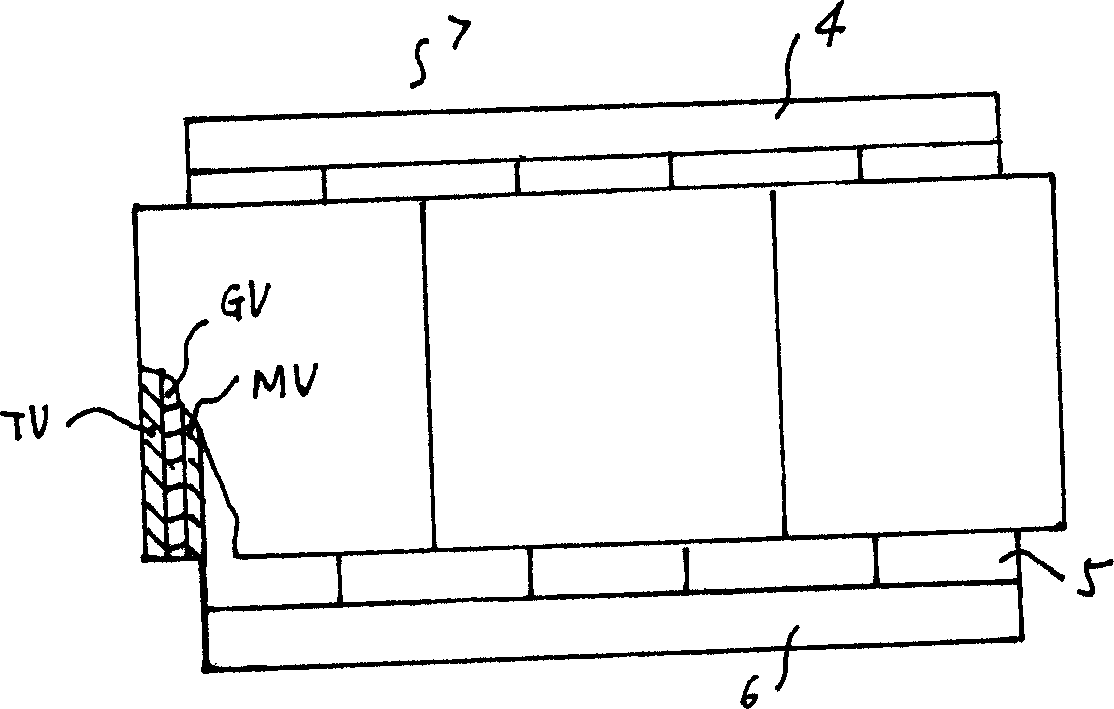

[0013] The present invention as Figure 1-5 As shown, it includes a magnetic circuit part composed of a constant flux body 7 and a variable flux body 8; the common winding MV 1-3 , Exciting I winding GV 1-3 , adjust the winding TV 1-3 , series winding HV 1-3 , exciter II winding JV 1-3 and capacitance C 1-3 Composed of circuit parts, the constant flux body 7 and the variable flux body 8 that make up the magnetic circuit part are all three-phase three-column types, and the two are arranged in a vertical or horizontal adjacent array, with 4 yokes on each body. There are longitudinal connecting plates 2 between the lower yokes 5, thereby forming a well-shaped structure, and insulating pads 3 are arranged between the longitudinal connecting plates 2 and the upper and lower yokes 4, 5, such as figure 1 , 2 shown, where: common winding MV 1-3 , Exciting I winding GV 1-3 , voltage regulating winding TV 1-3 Take one of them, form three groups and respectively set them on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com