Silt collection device

A collection equipment, sand settling technology, applied in the direction of sedimentation separation, feeding/discharging device of settling tank, chemical instrument and method, etc., can solve the problems of low work efficiency, equipment wear, high maintenance cost, etc., and improve work Efficiency, reduced operating costs, and less energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

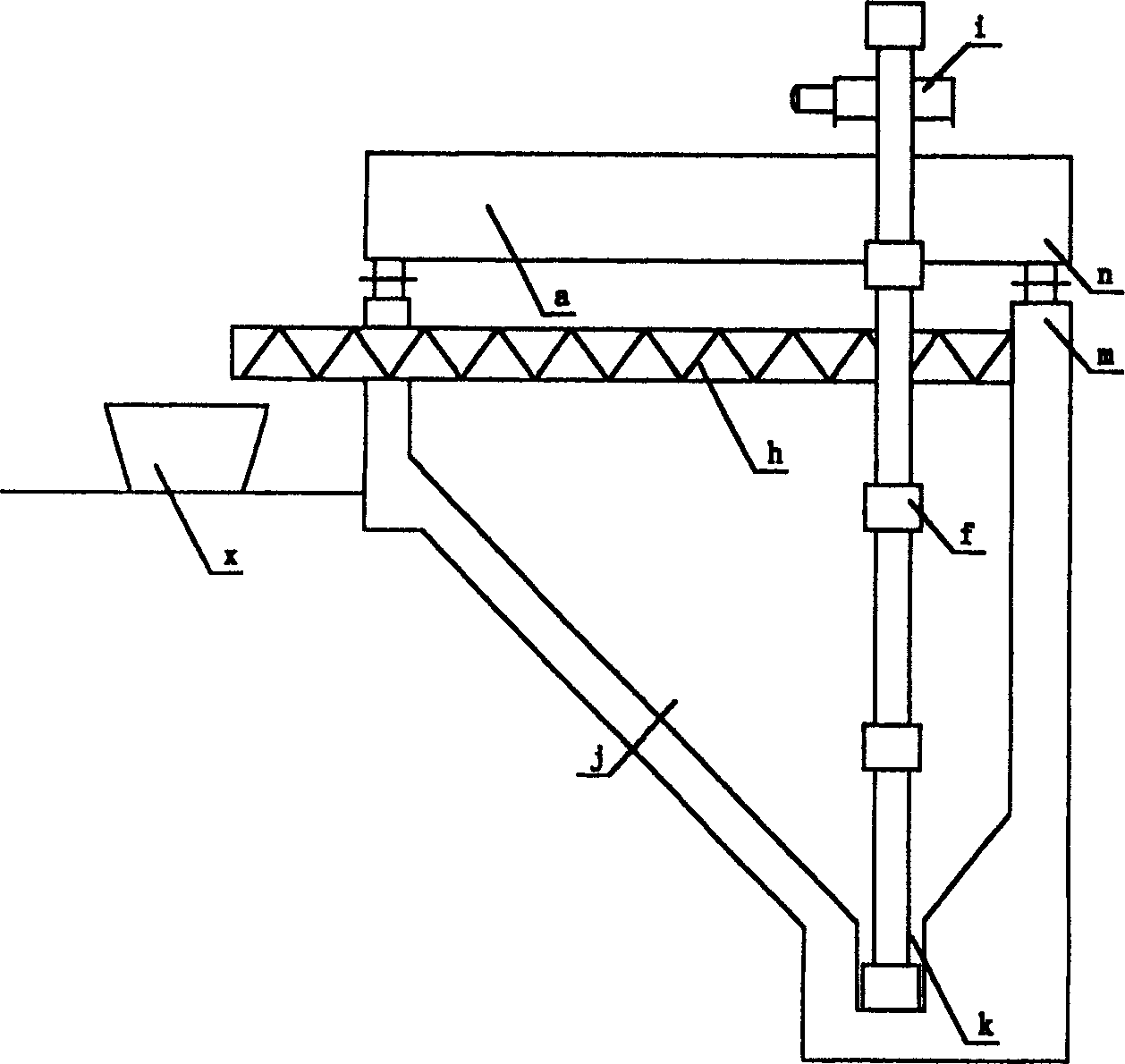

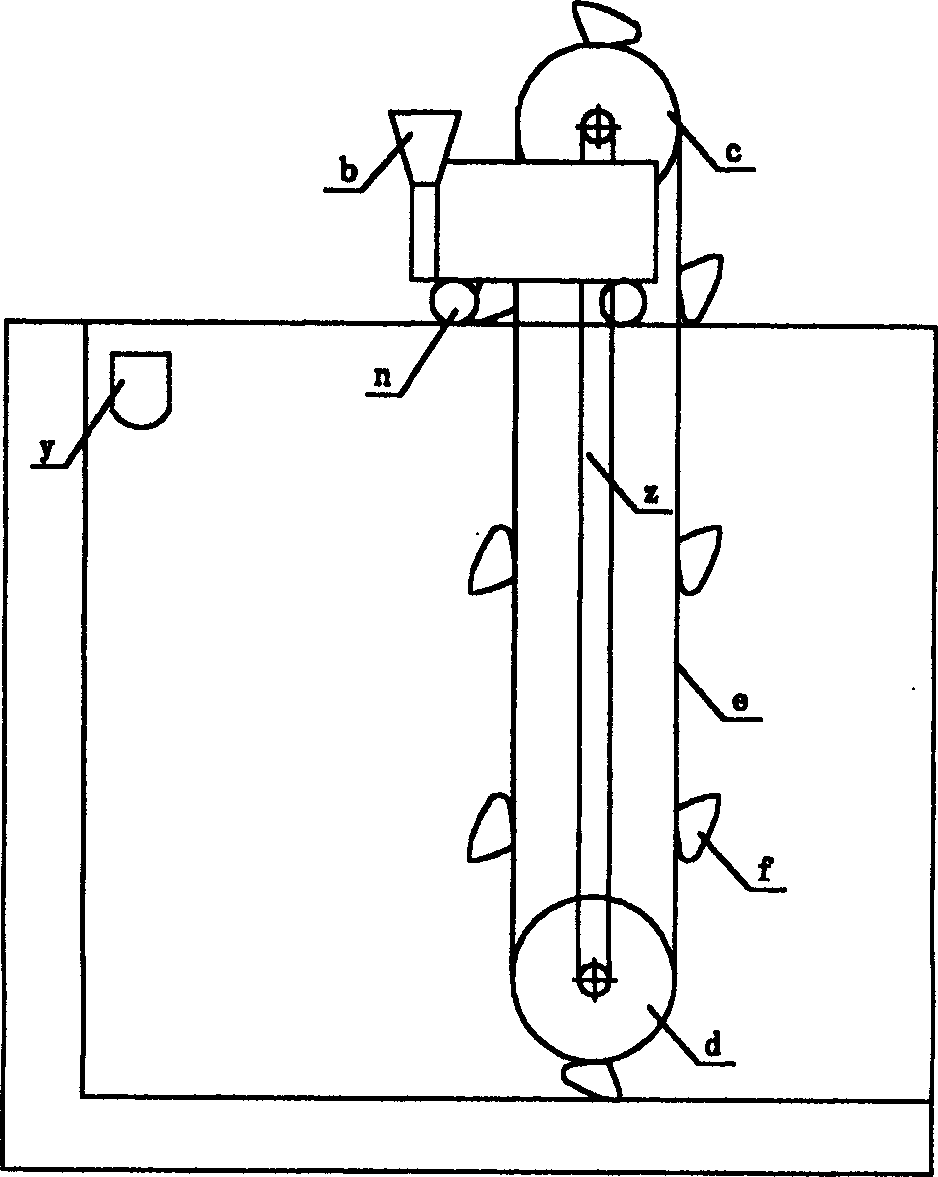

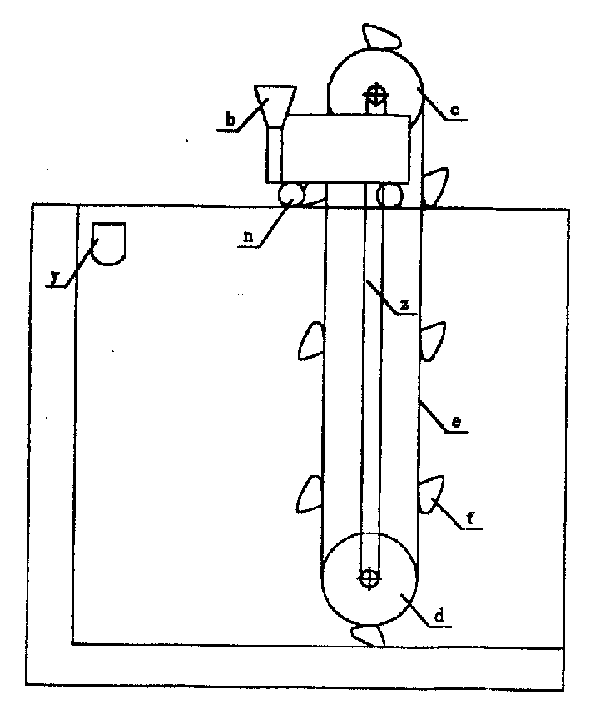

[0012] The structure of the present invention is as figure 1 , 2 As shown, it includes a mobile crane a with a sand storage bucket b, an upper runner c and a lower runner mounting frame z are arranged on the upper part of the crane a, the lower runner mounting frame z is provided with a lower runner d, and the upper runner c and the lower runner d are driven by a chain e, a bucket f is set on the chain e, the upper runner c is driven by a motor i, and the motor i is fixed on one side of the upper runner c, and is connected to the upper runner c through a reducer; One end of the aeration grit chamber j has a sand storage tank y, and a screw conveyor h is arranged in the sand storage tank y. The position of the sand storage bucket b is on one side of the chain, close to the turning point of the bucket f.

[0013] There is a narrow and long grit chamber k at the bottom of the aerated grit chamber j, and the grit generated during operation falls into the groove by gravity. Two p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com