Interlaminar bonding strength tester for pavement

A technology for bonding strength and pavement interlayers, applied to instruments, using stable shear force to test material strength, using stable tension/pressure to test material strength, etc., can solve the problem of inconvenient carrying test, bulky instrument, and poor function Single and other problems, to achieve the effect of accurate and reliable test data, convenient portability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

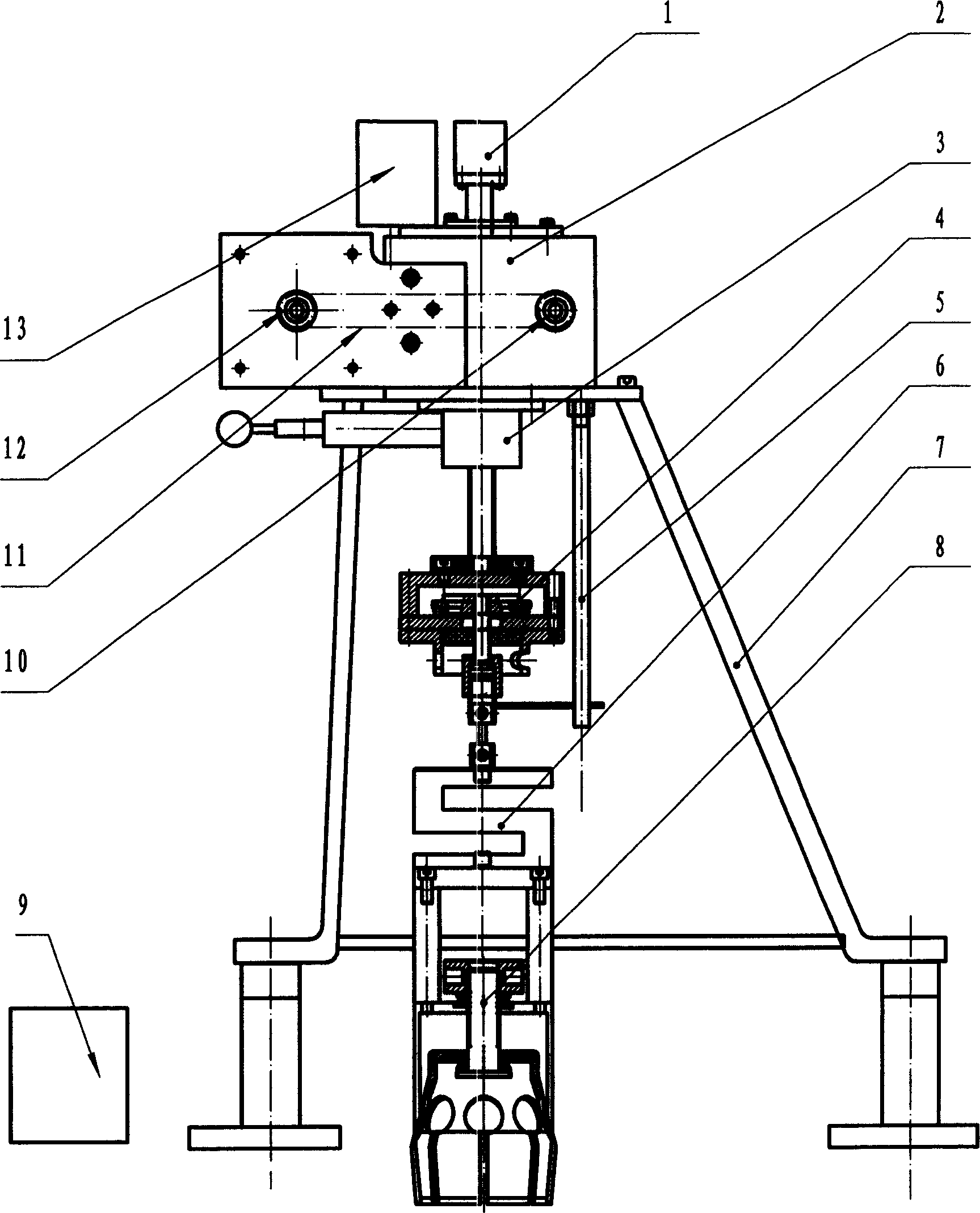

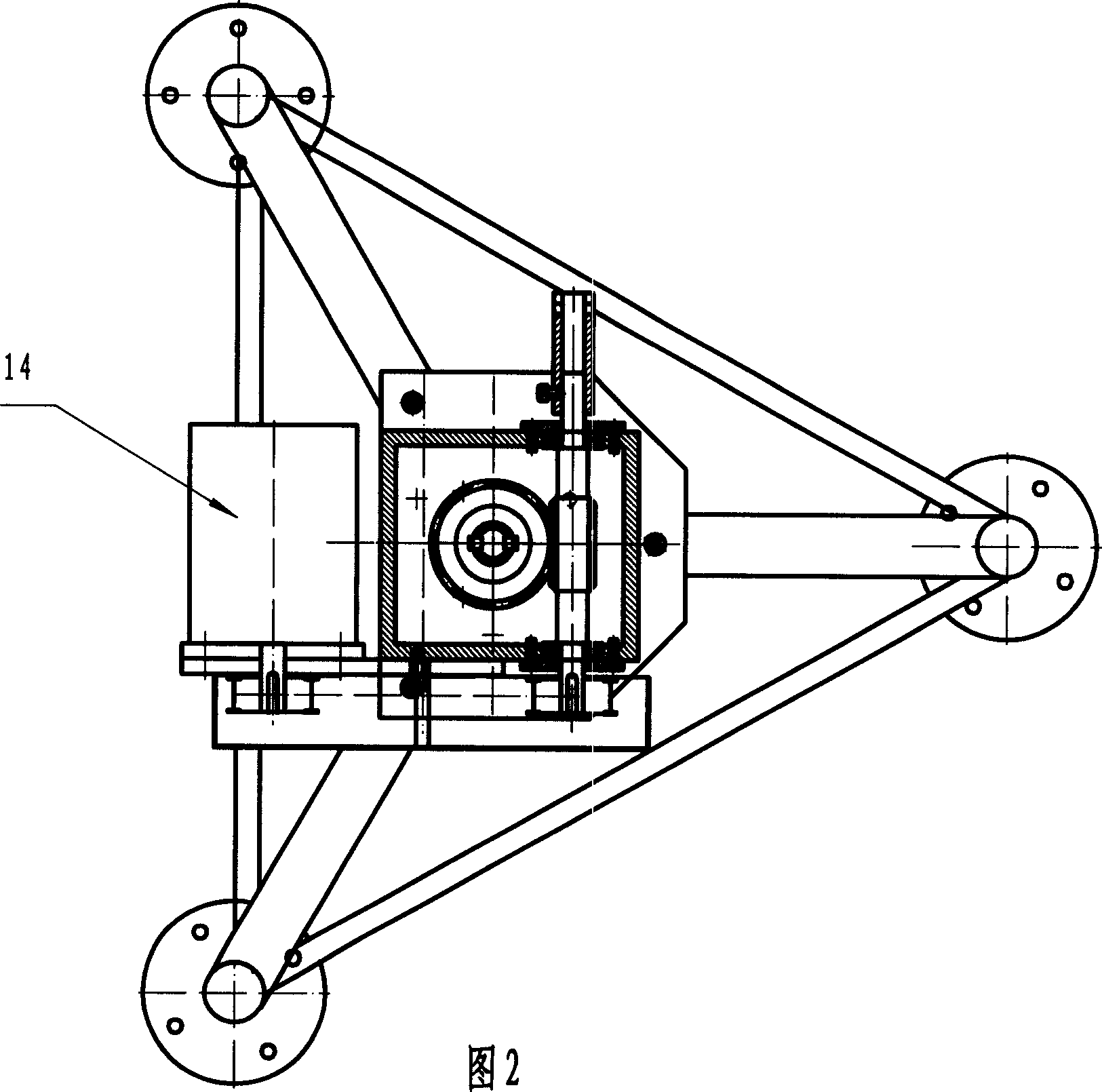

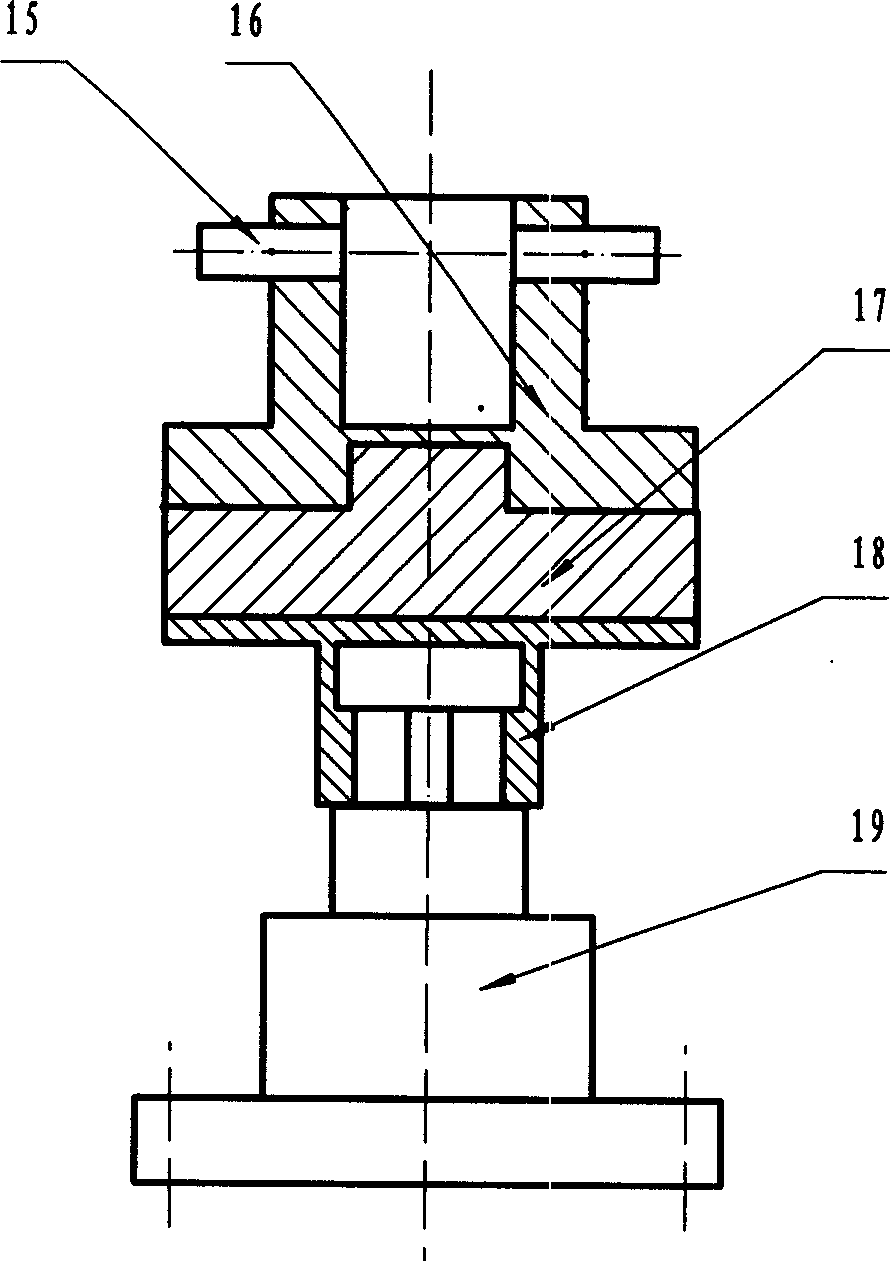

[0021] exist figure 1 , 2, 3, the pavement interlayer bonding strength tester of the present embodiment is composed of photoelectric encoder 1, speed reducer 2, control mechanism 3, eccentric conversion mechanism 4, torque balance bar 5, tension sensor 6, frame 7 , clamping mechanism 8, computer 9, driven sprocket 10, chain 11, driving sprocket 12, programmable controller 13, motor 14, pin 15, upper half coupling 16, cross coupling body 17, lower half Shaft coupling 18 and torque sensor 19 are connected to form, wherein pin 15, upper half coupling 16, cross coupling body 17, and lower half coupling 18 are connected into a shaft coupling.

[0022] The left side on the frame 7 is fixedly installed with a motor 14 with a threaded fastening connector, and the motor 14 provides power for the present invention, and the right side on the frame 7 is fixedly connected with a speed reducer 2 with a threaded fastening connector, and the motor The drive sprocket 12 is installed on the ou...

Embodiment 2

[0029] The central position of the lower backing plate 4-7 of the eccentric conversion mechanism 4 in this embodiment is processed with a 22mm center hole, and the outer diameter of the pull rod 4-4 is 12mm. Other components and the coupling relationship of the components are the same as in Embodiment 1.

Embodiment 3

[0031] The center position of the lower backing plate 4-7 of the eccentric conversion mechanism 4 in this embodiment is processed with a 36mm center hole, and the outer diameter of the pull rod 4-4 is 18mm. Other components and the coupling relationship of the components are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com