Fault collection and detection apparatus and method

A fault collection and detection device technology, applied in the direction of measuring devices, data collection and recording, instruments, etc., can solve the problems of increased production costs, large volume of industrial computer, high price of industrial computer, to prevent mutual interference, reduce power consumption, The effect of reducing the complexity of the power supply circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

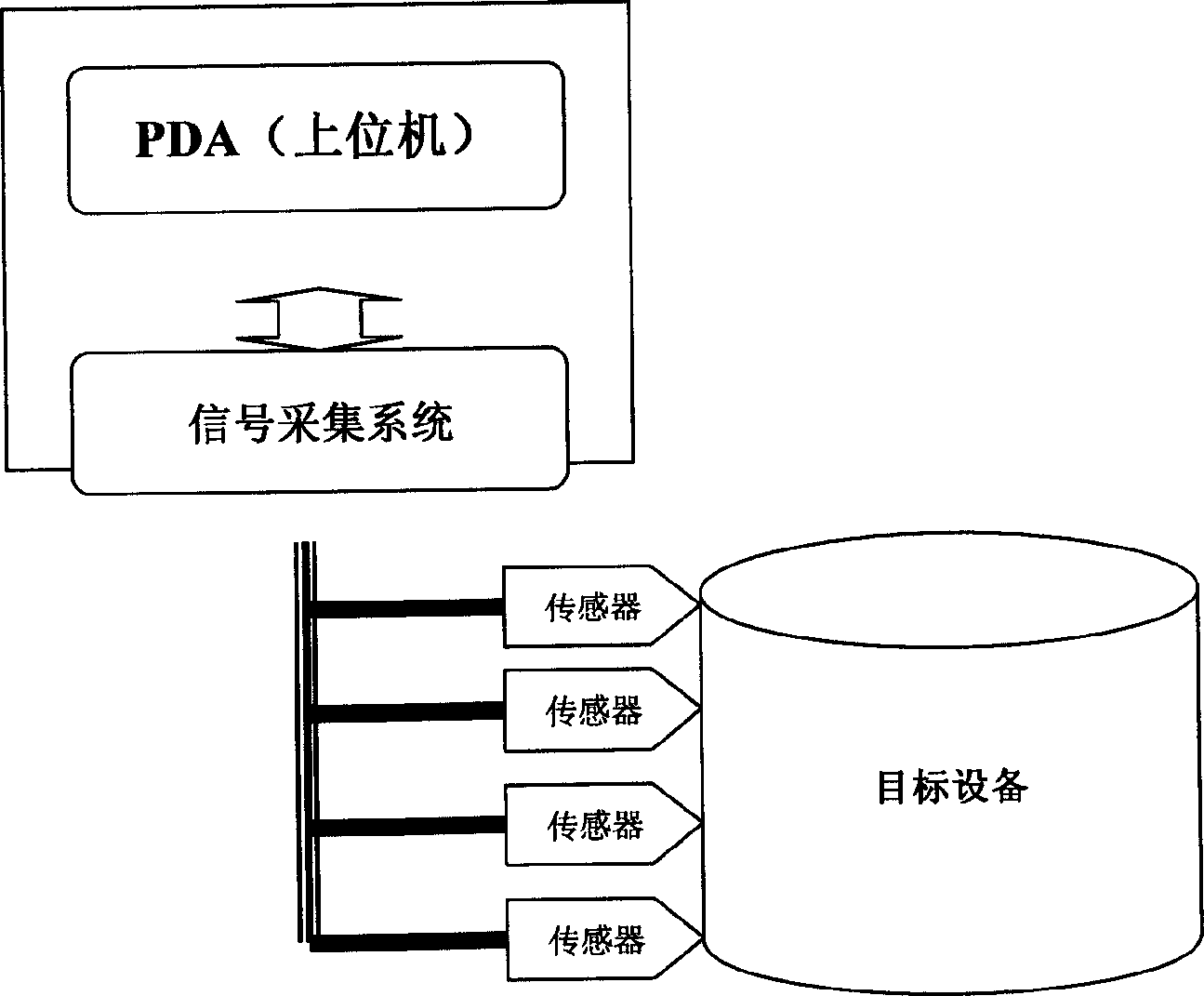

[0028] figure 1 A schematic diagram of connection of the present invention on site is given. The on-site vibration sensor can be fixed in multiple orientations of the target equipment, such as the X radial, Y radial, axial, etc. Equipment operation data such as vibration amplitude. The hardware circuit of the lower computer includes MCU part, power supply part, analog part, external expansion SRAM and serial port part.

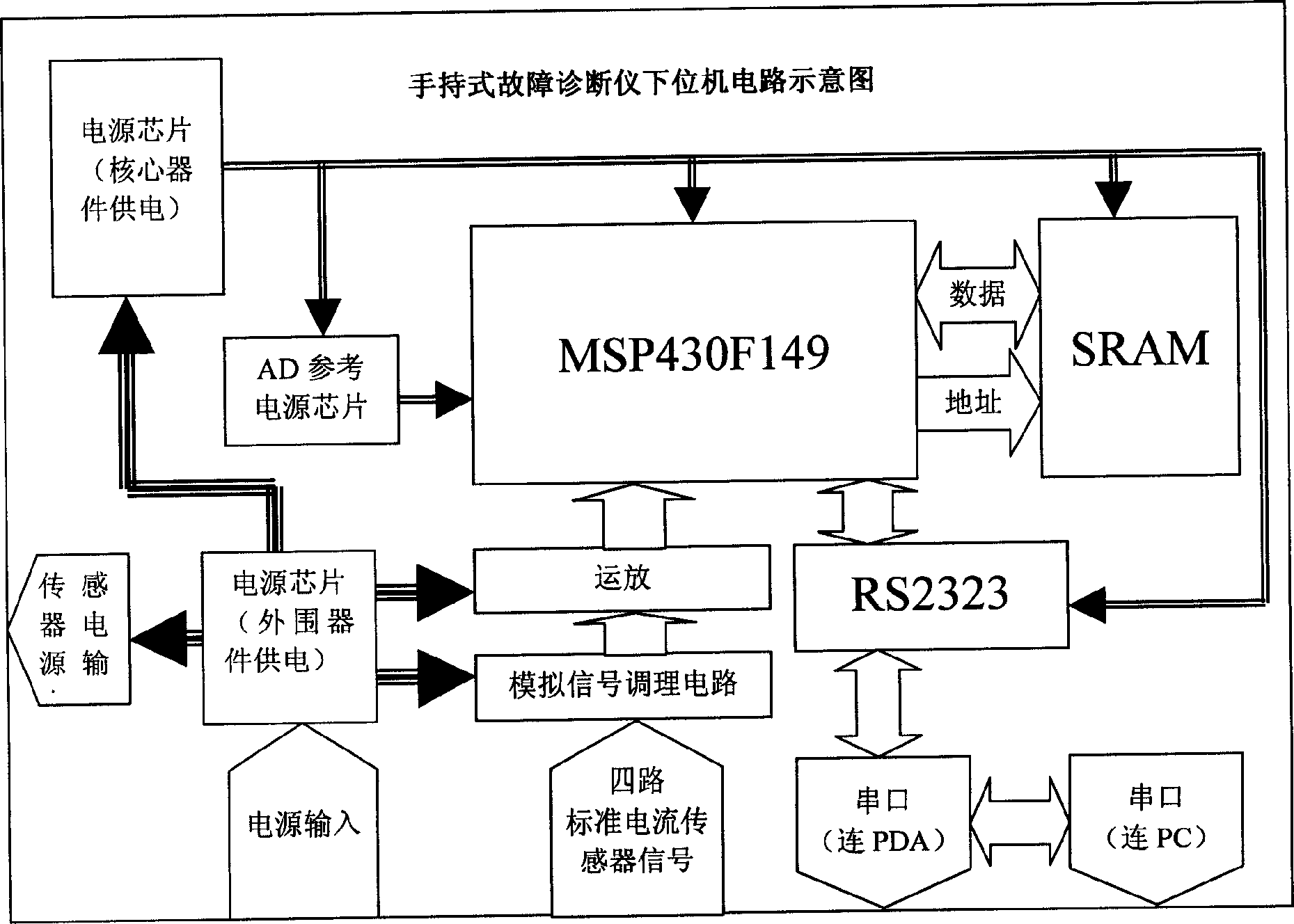

[0029] figure 2It is the overall frame diagram of the hardware of the lower computer. The multi-channel sensor analog signal connected to the target device in the industrial field passes through the signal conditioning circuit to obtain the spectrum range signal that needs to be collected, and then passes through the integrated operational amplifier to amplify the signal to the input voltage range of the AD inside the MCU. The integrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com