Low-voltage punch-through bi-directional transient-voltage suppression devices having surface breakdown protection and methods of making the same

A transient voltage suppression and device technology, which is applied in semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor/solid-state device components, etc., can solve problems such as increasing costs, and achieve the effect of preventing surface breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Those skilled in the art will be able to realize that the following description is illustrative only and not limiting. Other embodiments of the invention will be readily apparent to the skilled artisan.

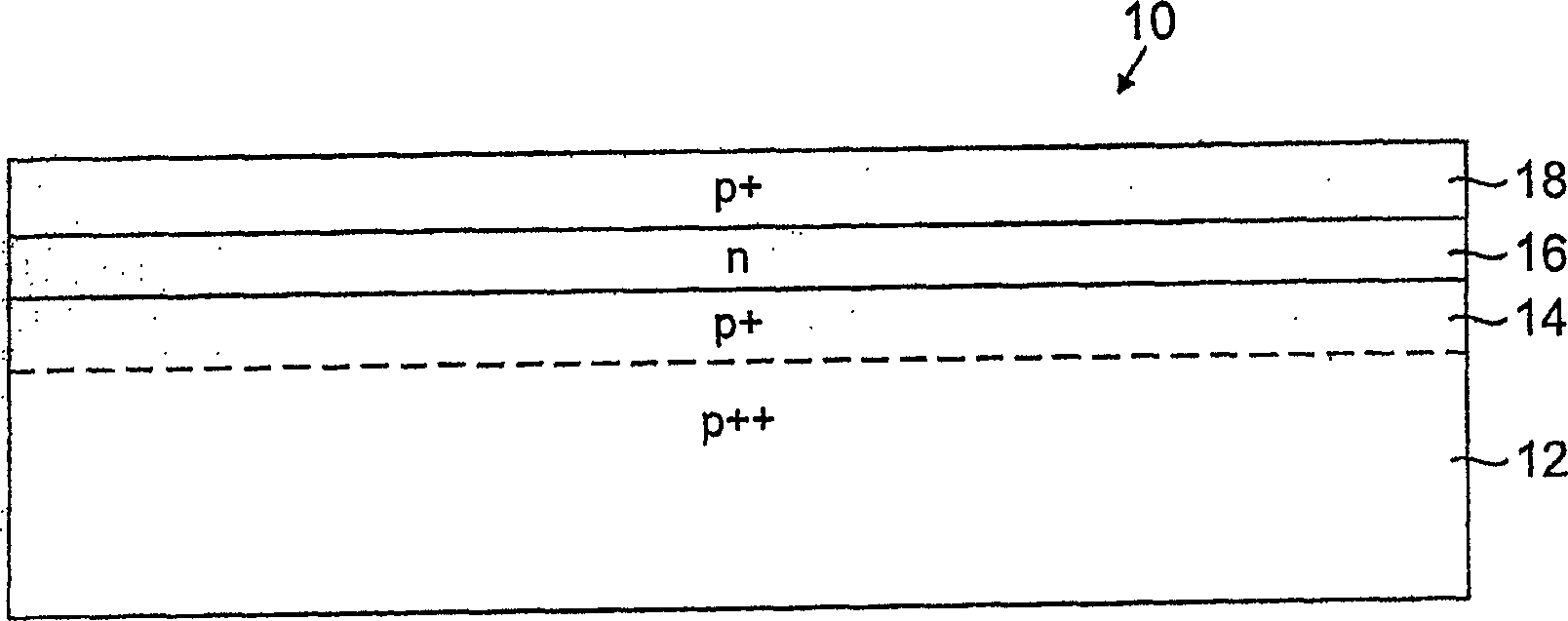

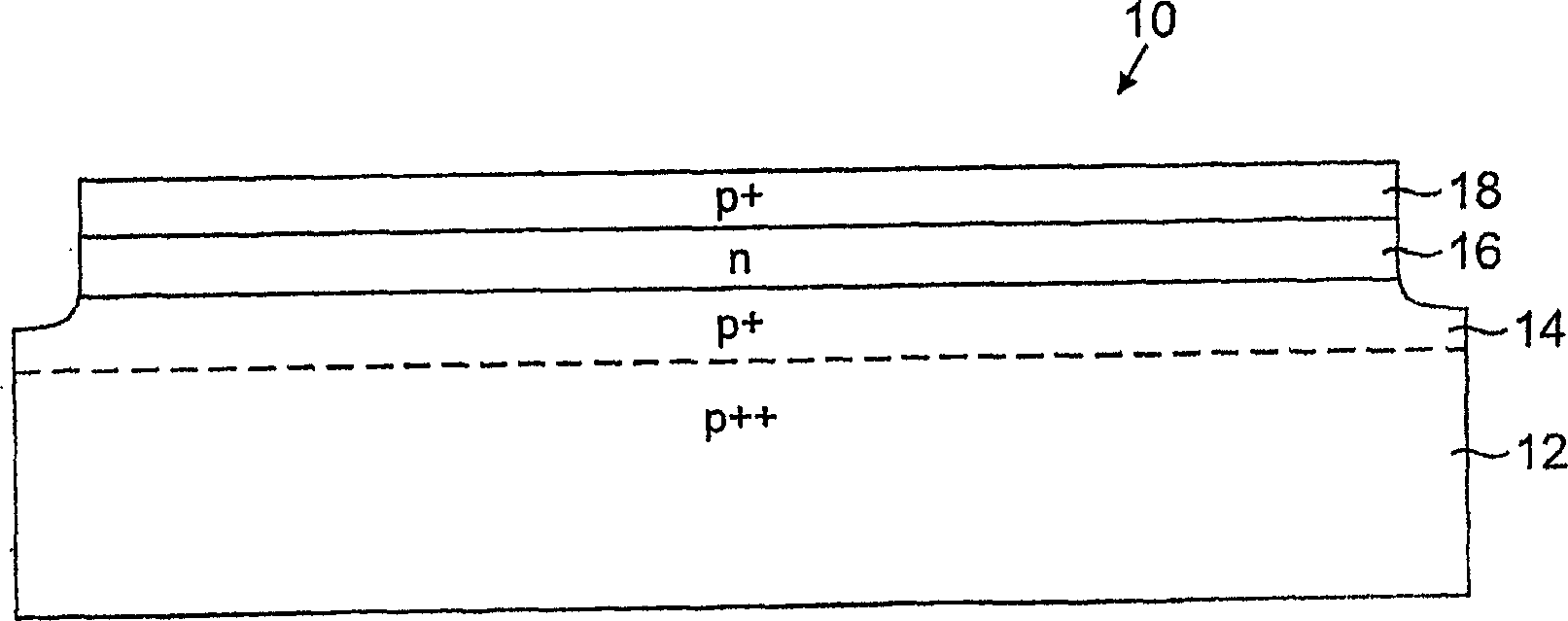

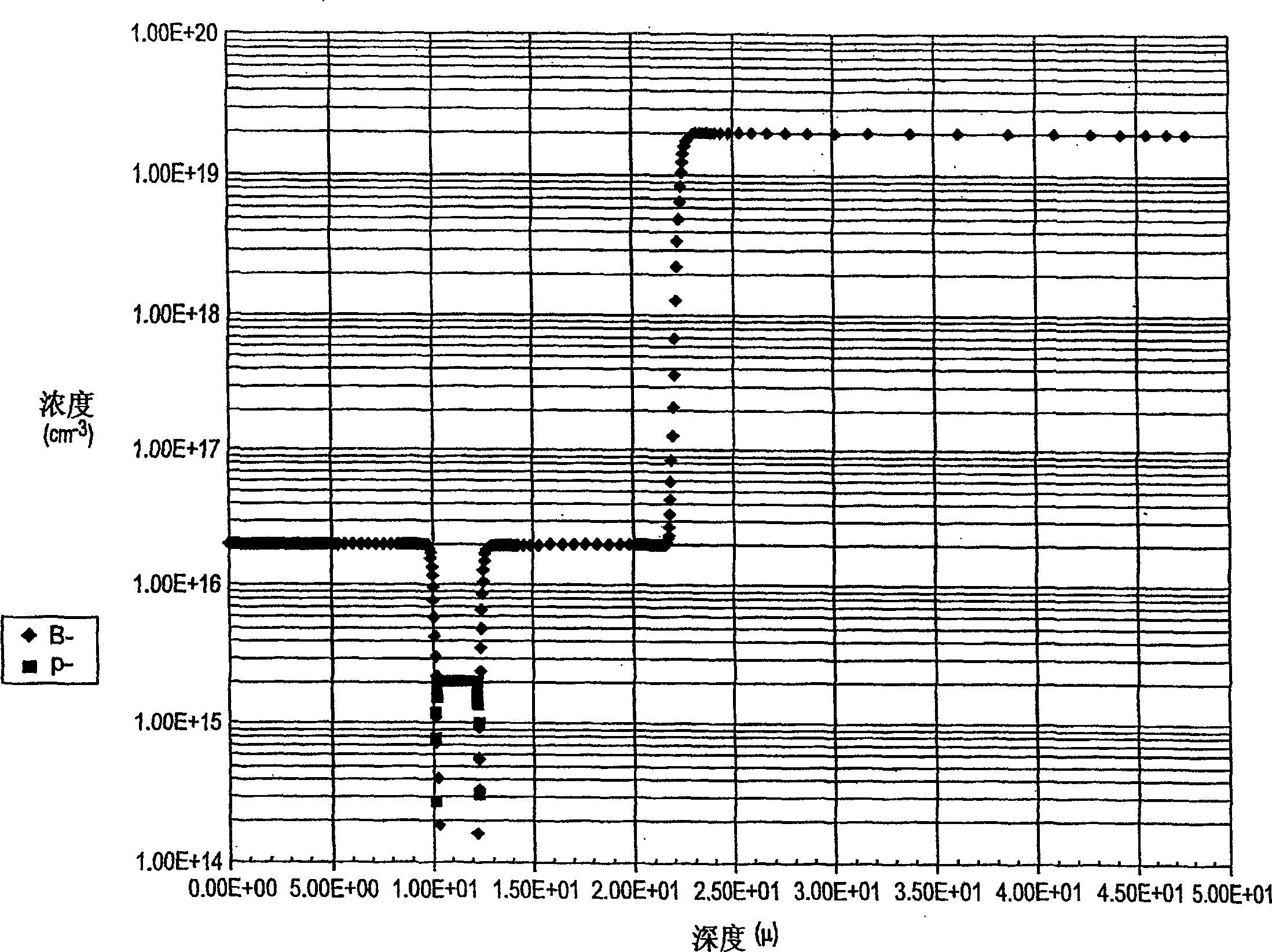

[0028] refer to figure 1, schematically shows a p++p+np+ three-layer epitaxial punch-through bidirectional transient voltage suppressor 10 according to the present invention with a cross-sectional view. The device of the present invention is formed on a p++ semiconductor substrate 12 . On the p++ substrate, three regions are grown epitaxially, preferably in one continuous process. First epitaxial p+ region 14 is initially formed on the upper surface of p++ region 12 . Epitaxial n region 16 is then formed on the upper surface of p+ region 14 and a second epitaxial p+ region 18 is formed on the upper surface of n region 16 . A p++ ohmic contact (not shown) is typically provided on the upper surface of p+ region 18 . This device contains two junctions: (1) the juncti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com