Two-purpose grinding machine for lead screw and external circle

A dual-purpose, grinding machine technology, applied in the field of machine tools, can solve the problems of long lateral moving table, high manufacturing cost, long bed guide rails, etc., and achieve the effects of maintaining accuracy, low production cost and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

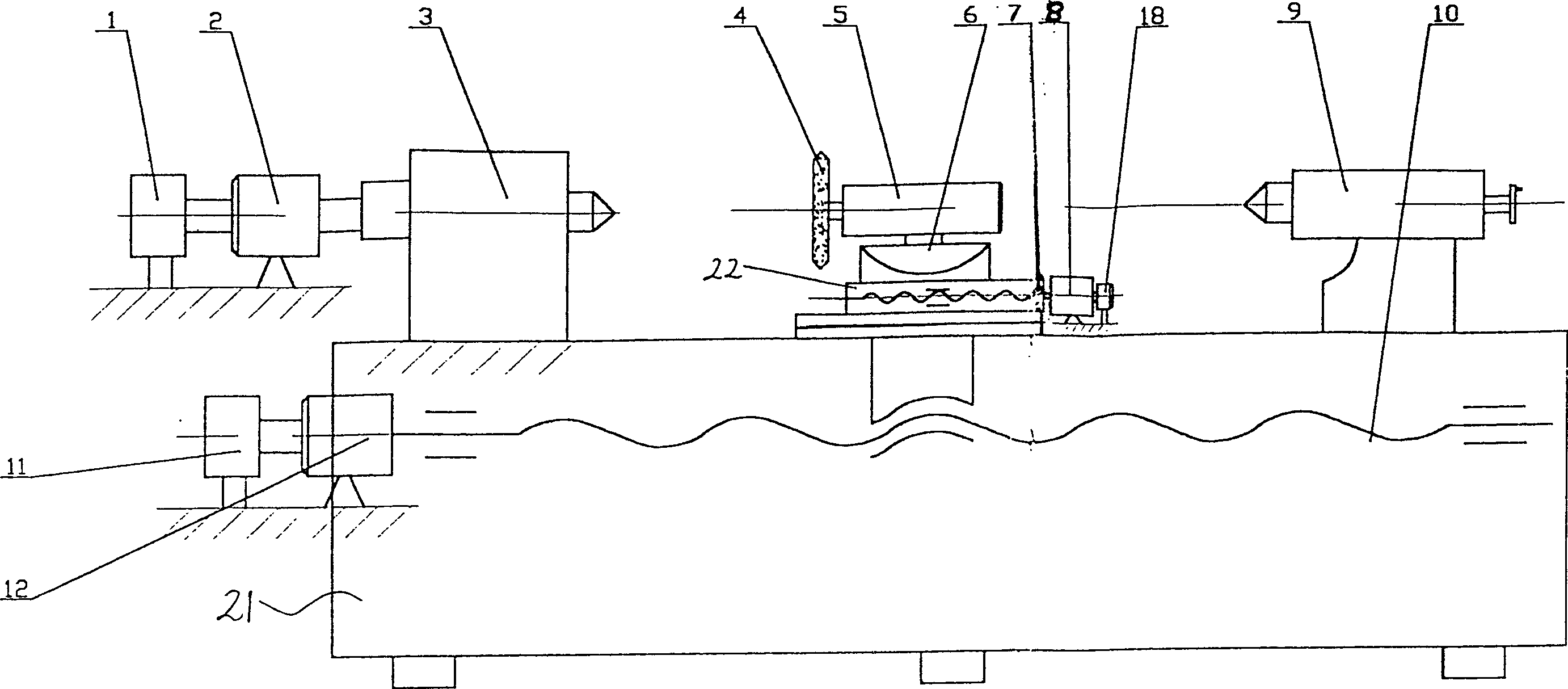

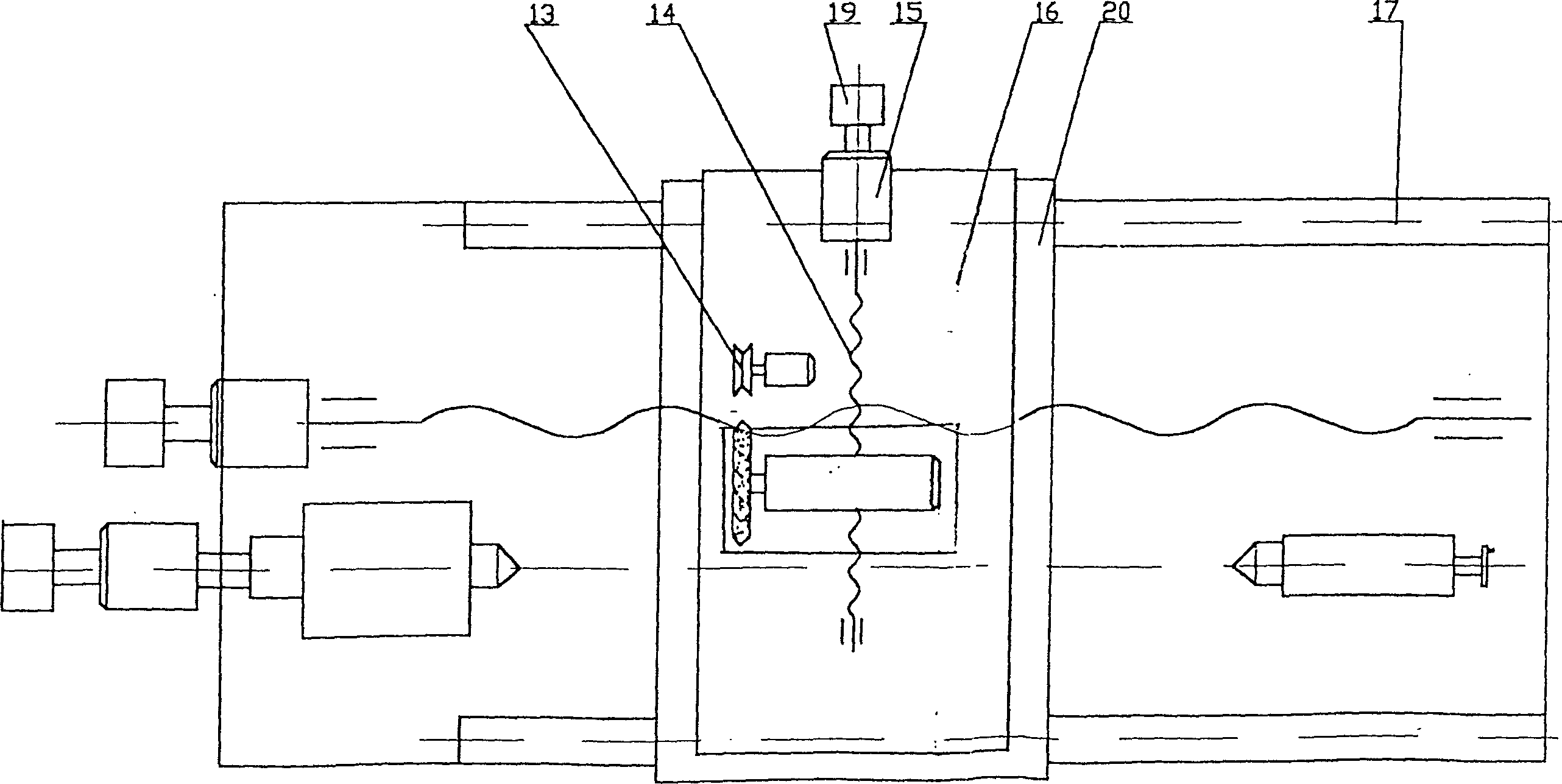

[0013] Specific embodiments: a dual-purpose grinding machine for a lead screw and an outer circle, including a bed 21, a headstock 3, a tailstock 9, a lateral movement mechanism, and a longitudinal movement mechanism. The headstock 3 is fixed on the bed 21, and the headstock 3 Connected with the servo motor 2 controlled by the rotary encoder 1, the tailstock 9 is movably installed on the linear guide rail 17 of the bed, and can move laterally along the guide rail 17 of the bed. Mobile installed on the bed guide rail 17, the transverse carriage 20 is connected with the first ball screw pair installed below it, the first ball screw pair includes the nut and the spindle ball screw 10 installed under the transverse carriage 20 , the main shaft rolling screw 10 is connected with the servo motor 12 controlled by the rotary encoder 11, the horizontal carriage 20 is connected with the longitudinal carriage 16 moving longitudinally through the second ball screw pair, and the second ball...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com