Power supply method and connection configuration for train power network on magnetic suspension train without power tracks

A vehicle-mounted power grid and maglev train technology, which is applied to current collectors, electric vehicles, vehicle components, etc., can solve the problems of high infrastructure costs for maglev train lines, reduce the efficiency of high-power repeated discharge, and increase the workload of inspection and maintenance. The effect of maintenance workload, easy promotion and use, and long continuous working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

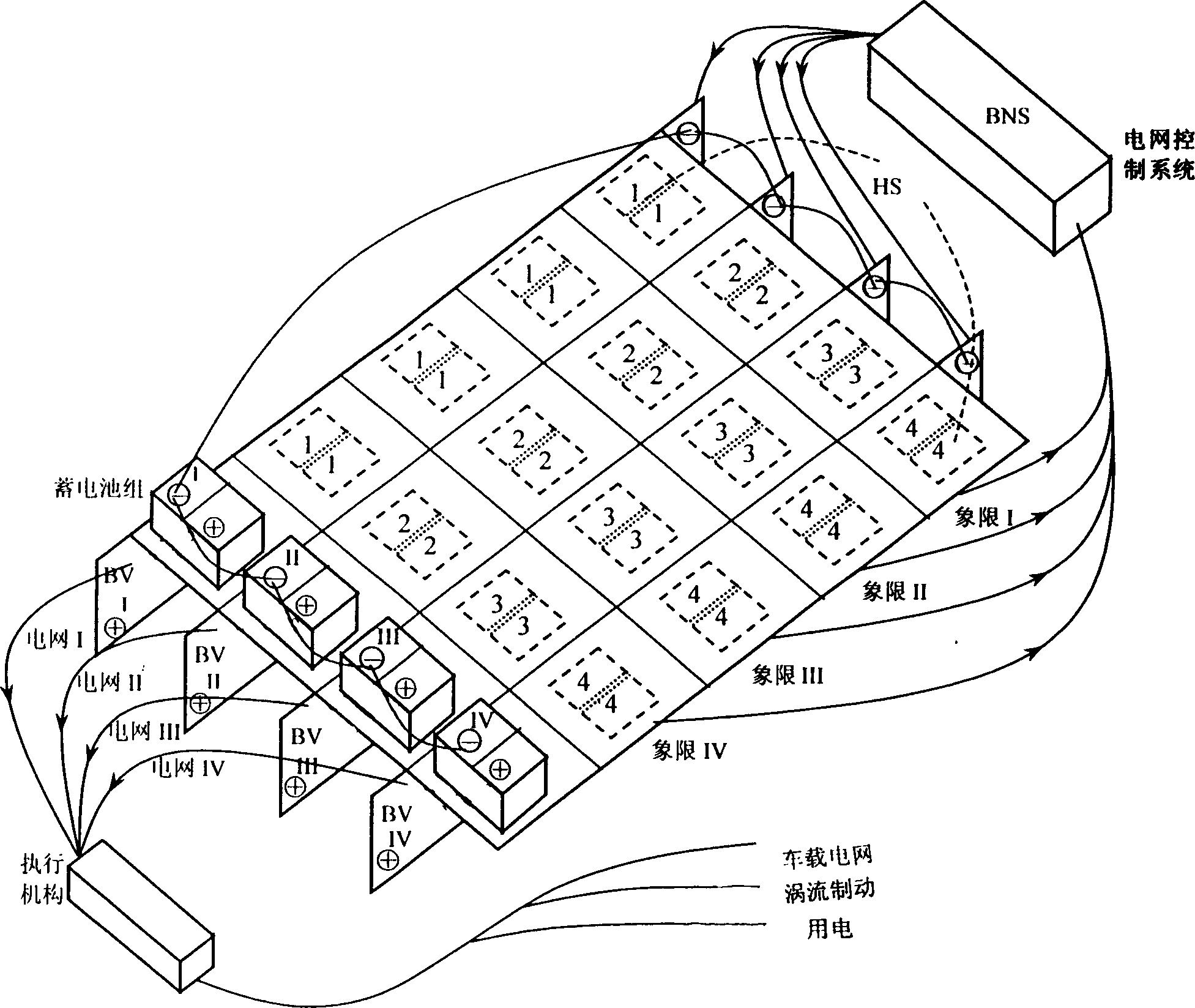

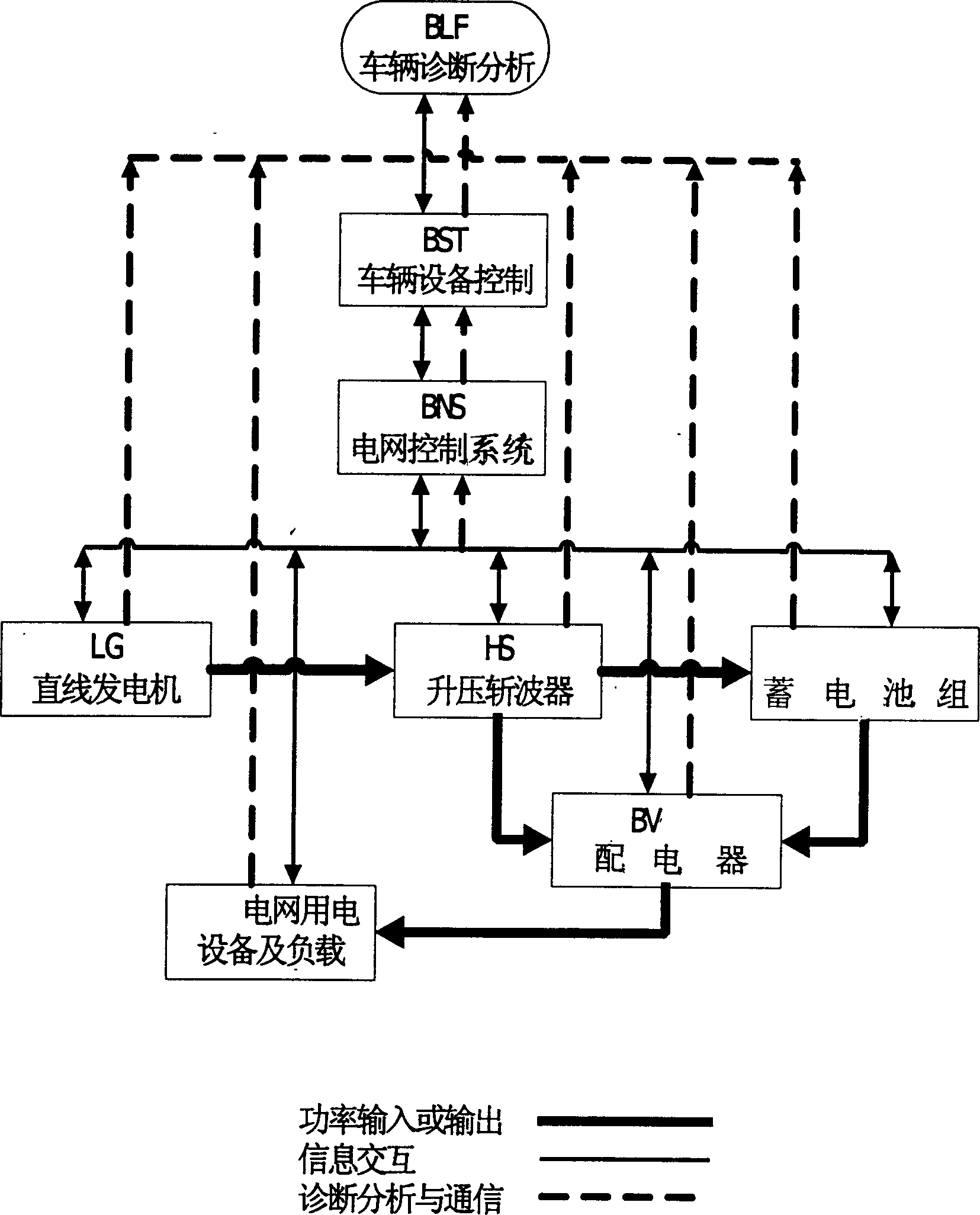

[0027] See figure 2 As shown, the vehicle power grid of the present invention includes a linear generator LG, a step-up chopper HS, a power distributor BV and a power grid control system BNS. The induced electromotive force of the linear generator LG rises with the speed of the train. Therefore, it must be matched with the step-up chopper HS before the power can be input into the vehicle power grid with a constant voltage (eg 440V). Each carriage of a maglev train is generally equipped with 32 step-up choppers HS directly connected to the linear generator LG, and the above-mentioned step-up choppers HS directly connected to the linear generator LG are divided into four quadrants I -IV, the choppers HS in each quadrant I-IV are divided into four groups of 1, 2, 3, and 4, and the choppers HS of the same group number in each column are connected to form four columns, and each column is connected to a Corresponding distributors BVI-IV are connected to form four sets of power gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com