Auxiliary cloth-handling mechanism for sewing machine

A sewing machine and mopping technology, applied in the field of sewing machines, can solve the problems of complex structure, high price, and high technical requirements for manufacturing and installation, and achieve the effects of simple structure, low price and high precision requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

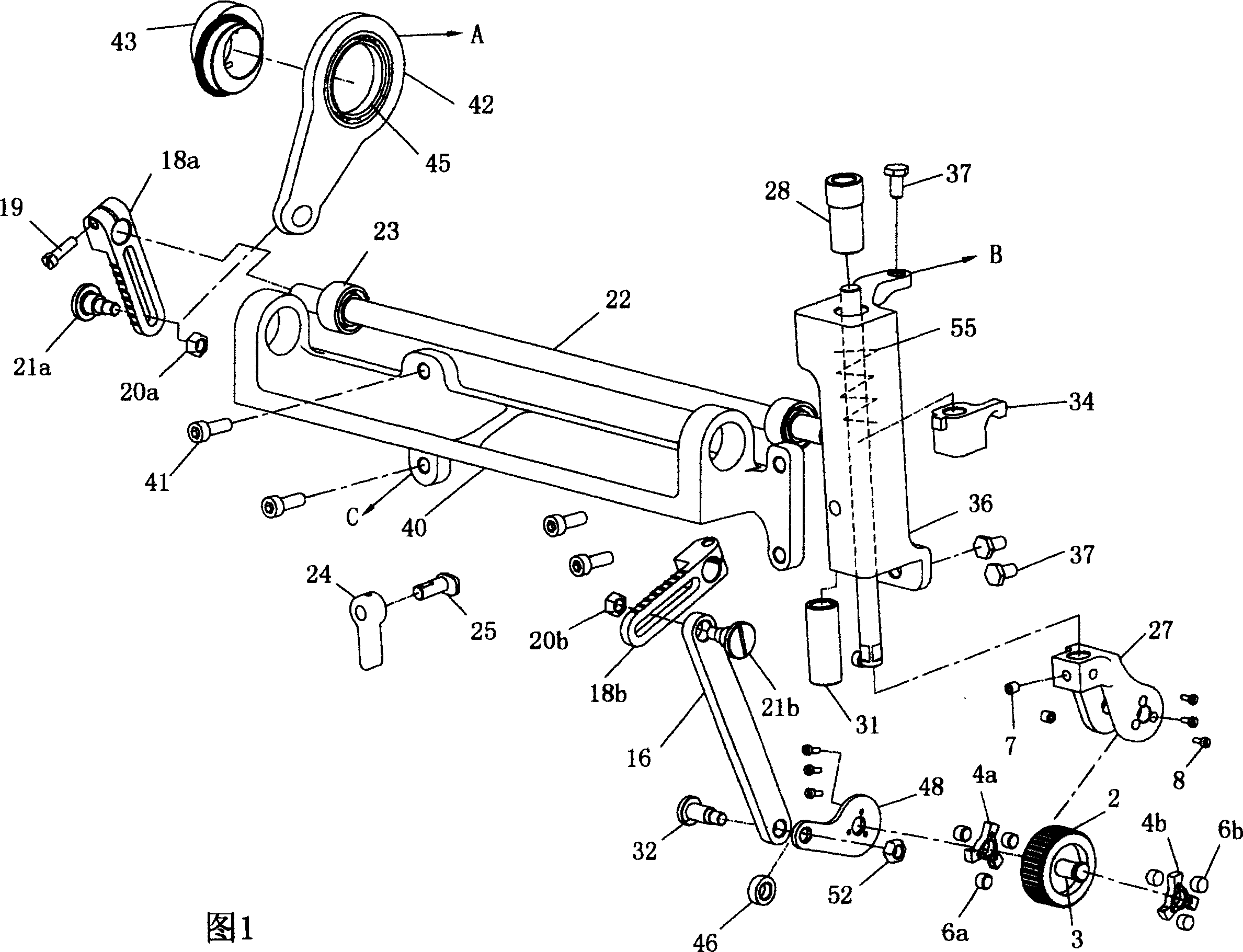

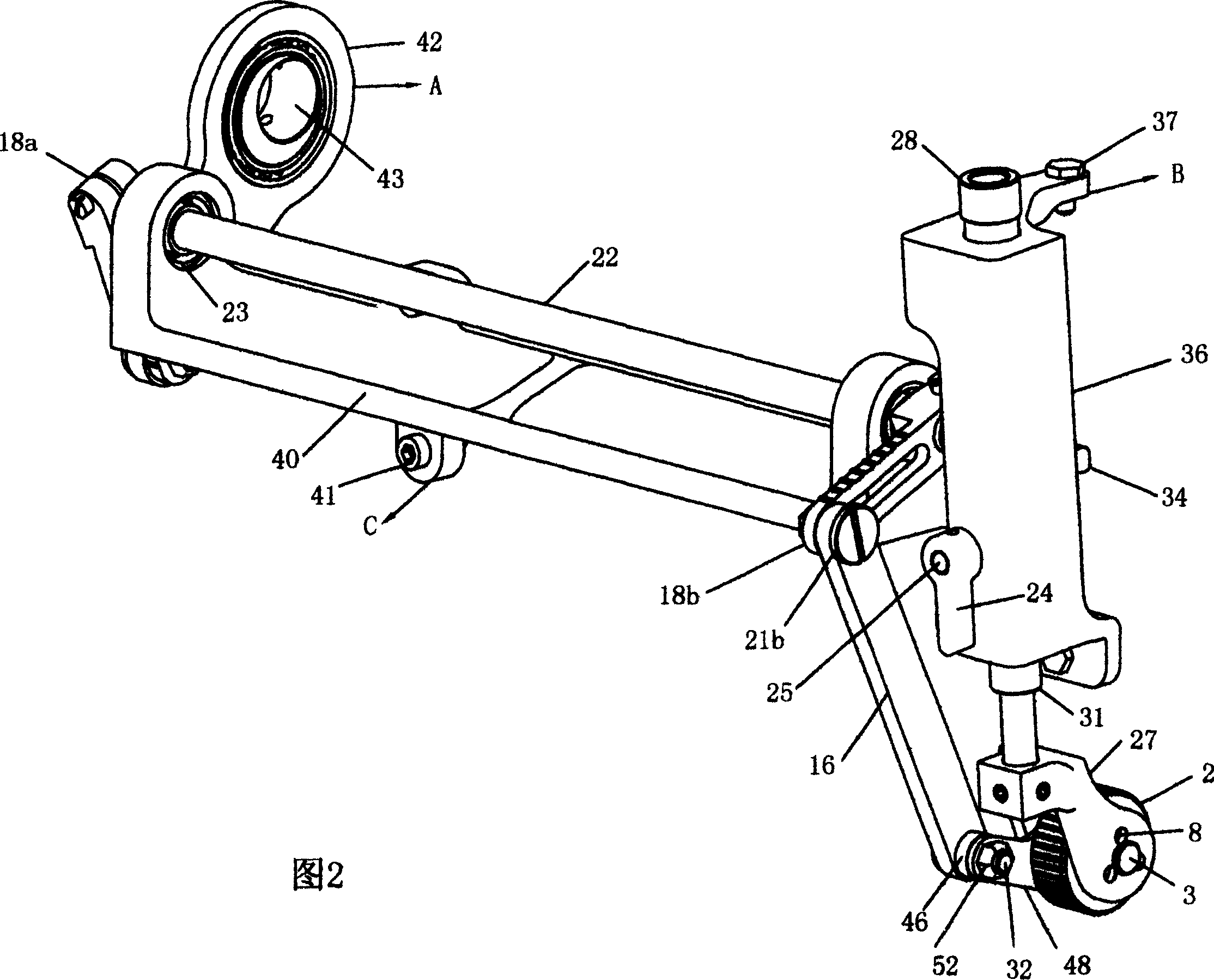

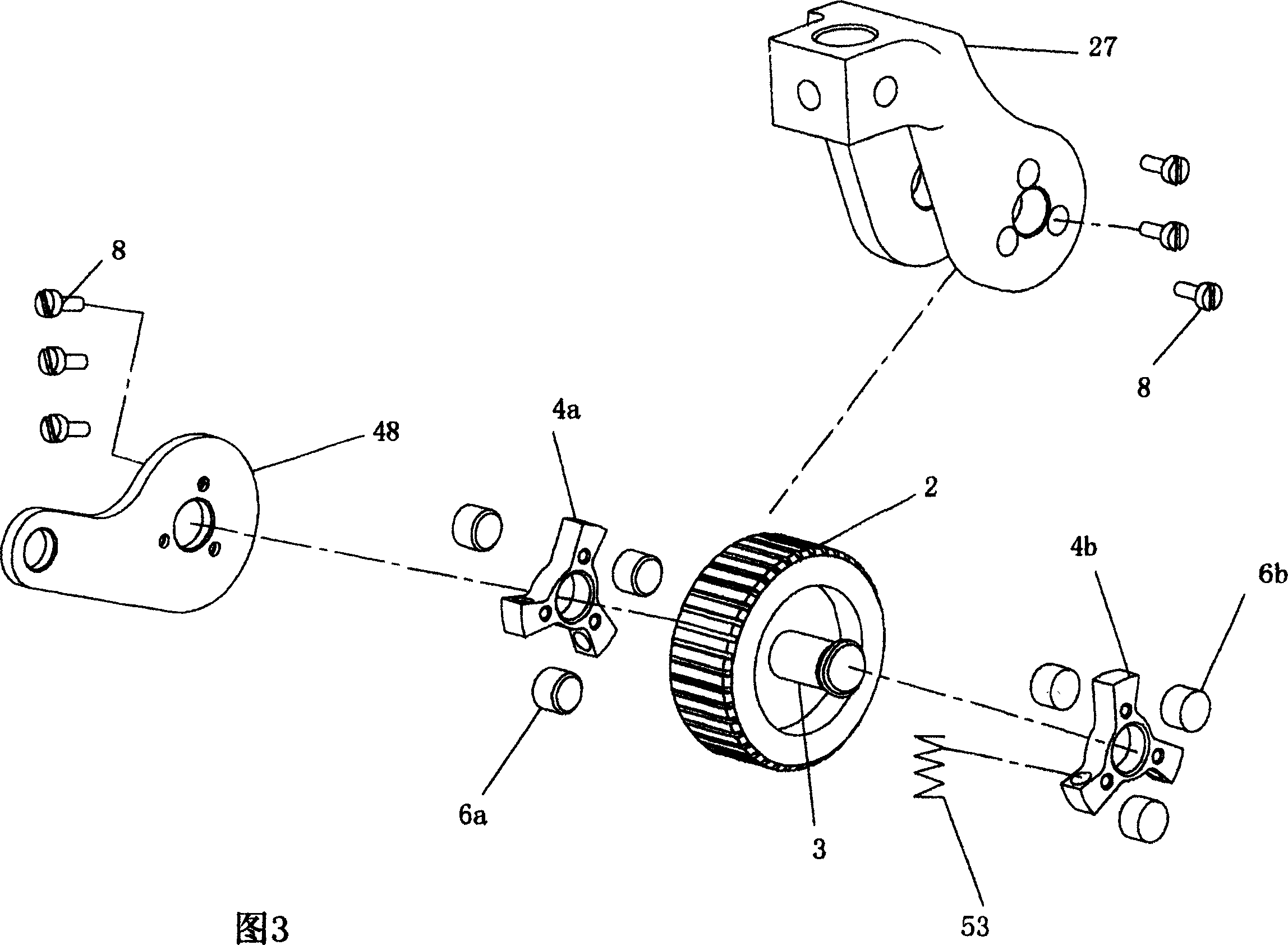

[0023] The auxiliary cloth mopping mechanism of the sewing machine of the present invention includes a swing mechanism composed of a swing shaft 22 installed on the base frame 40 and swing assemblies at both ends thereof, a one-way rotation mechanism composed of a lower cloth wheel and a rotating locking assembly in its abdominal cavity, The adjustment mechanism of the lower cloth wheel mainly composed of the pressure rod, its guide block and the large spring. The swing mechanism is connected with the one-way rotation mechanism through the cloth wheel connecting rod 48, and the one-way rotation mechanism is passed through the long support of the cloth wheel. 27 is connected with lower cloth wheel adjusting mechanism. The following are their specific structures.

[0024] 1. The connection relationship between the swing shaft and its two ends (swing mechanism).

[0025] As shown in FIGS. 1 and 2 , the swing shaft bearings 23 installed on the swing shaft 22 are fixed in the hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com