Voltage blocked diaphragm and producing method thereof

A technology of voltage clamping and diaphragm, which is applied in the direction of circuits, electrical components, battery pack components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] specific implementation

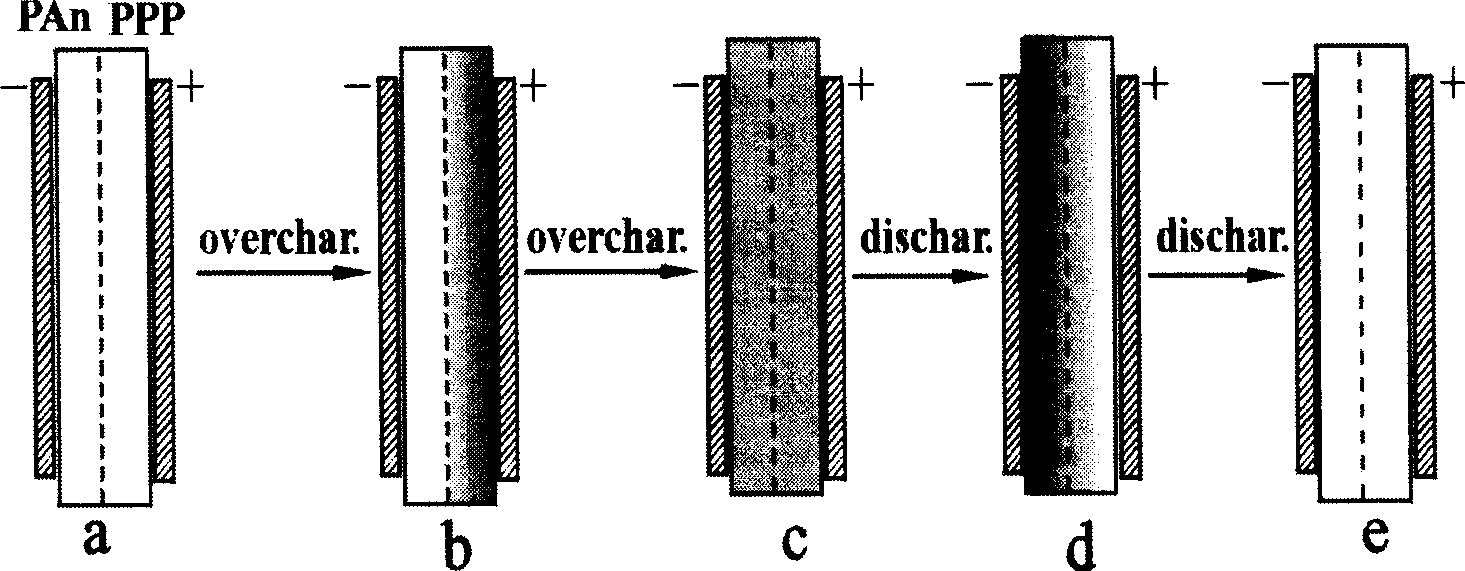

[0018] Application examples. Using polyaniline (PAn) and polyphenylene (PPP) as electroactive polymer materials on the negative side and positive side of the separator, nano-SiO 2 Powder is an inert component additive, polytetrafluoroethylene (PTFE) emulsion is a binder, and rolls are used to make films with a thickness of about 25 μm, and then the two films are laminated and integrated by hot pressing. With this integrated PPP / PAn composite film as a separator, LiCoO 2 as positive electrode, Li sheet as negative electrode, 1mol / L LiPF 6 The / EC+DMC solution was used as the electrolyte to assemble the experimental lithium battery. In the assembled battery, the PPP side of the composite film is next to the LiMn 2 o 4 electrode, while the PAn face is next to the Li electrode.

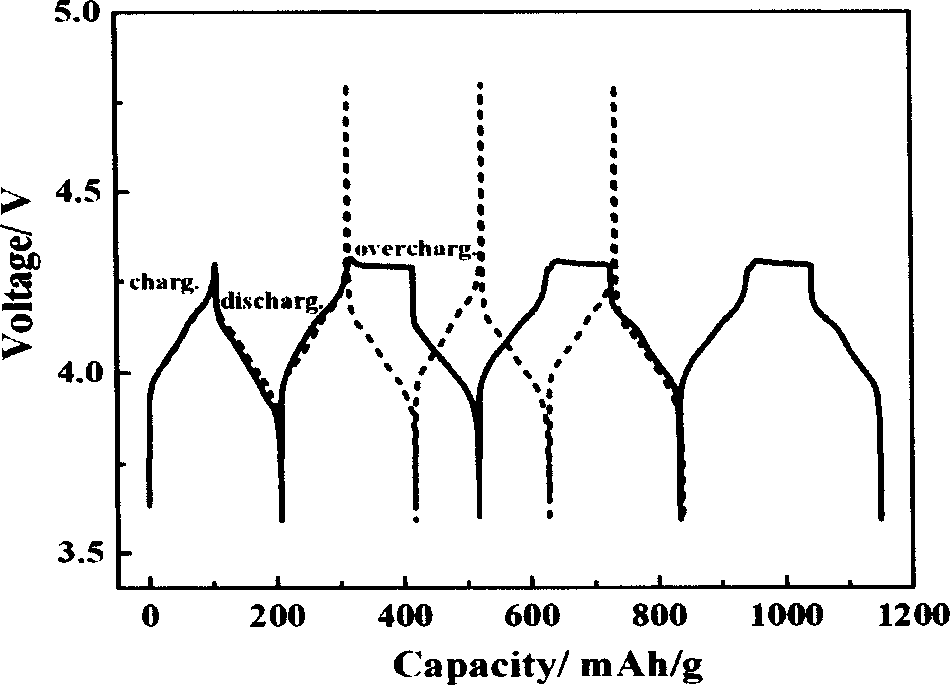

[0019] figure 1 Comparing Li / LiMn with conventional polypropylene separator and PPP / PAn composite film 2 o 4 The charging and discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com