Plasma processing device and plasma processing method

A plasma and processing device technology, which is applied in the fields of plasma, semiconductor/solid-state device manufacturing, coating, etc., can solve the problems of poor thermal protection film plasma processing and high plasma temperature, and achieves improved plasma processing performance and increased plasma temperature. The effect of high plasma density and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1-5

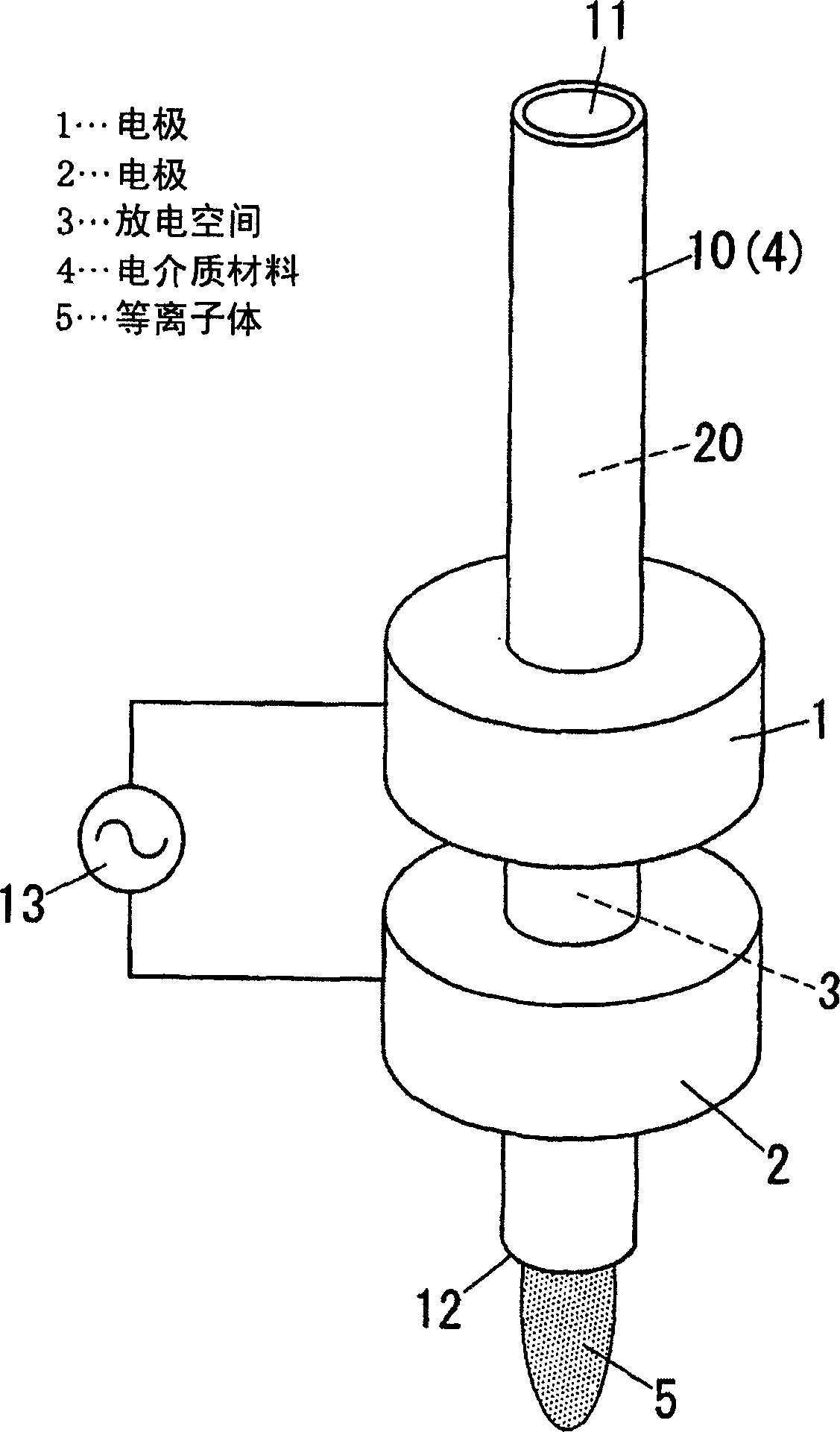

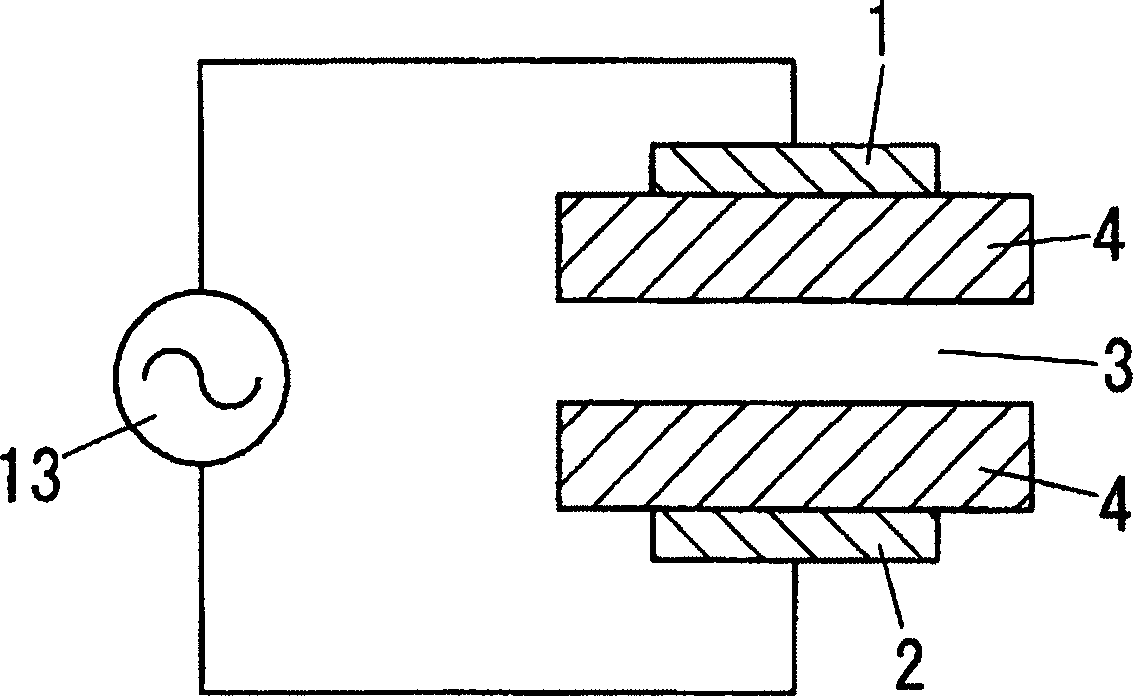

[0164] use as Figure 16 The plasma treatment apparatus shown is for spot treatment. The reactor 10 of the plasma processing apparatus was made of a quartz tube having an inner diameter of 3 mm and an outer diameter of 5 mm, which had a hollow flange portion 6 (storage area 15) having an outer diameter of 50 mm. The electrodes 1, 2 and the flange portion 6 are arranged to have as Figure 17 The cross-sectional structure shown in .

[0165] A plasma generating gas is supplied from an inlet 11 of the reactor 10 to the gas flow channel 20, and plasma is generated by a voltage supplied from a power source 13 connected to the electrode 1 on the upstream side and the electrode 1 on the downstream side. Electrode 2. Plasma 5 emerges from outlet 12 . Plasma treatment is achieved by exposing the object on the downstream side of the outlet 12 to the plasma. A mixture of argon and oxygen was used as the plasma generation gas. Other conditions for generating plasma are shown in Tabl...

example 11

[0203] use as Figure 18 The plasma treatment apparatus shown is for spot treatment. The reactor 10 of this apparatus was obtained by forming a conical nozzle portion 14 with an outlet 12 having an inner diameter of 1 mm on the lower side of the reactor 10 of Examples 1 to 5. Other structures are basically the same as examples 1 to 5. Plasma 5 was generated under the plasma generation conditions shown in Table 4. As in the case of Examples 1 to 5, evaluation was performed.

example 12

[0205] use as Figure 15 The plasma treatment apparatus shown is for spot treatment. The reactor 10 of this apparatus was obtained by forming a conical nozzle portion 14 with an outlet 12 having an inner diameter of 1 mm on the lower side of the reactor 10 of Comparative Examples 1 and 2. Other structures are basically the same as examples 1 to 5. Plasma 5 was generated under the plasma generation conditions shown in Table 4. As in the case of Examples 1 to 5, evaluation was performed. The above evaluation results are shown in Table 4.

[0206] Example 11

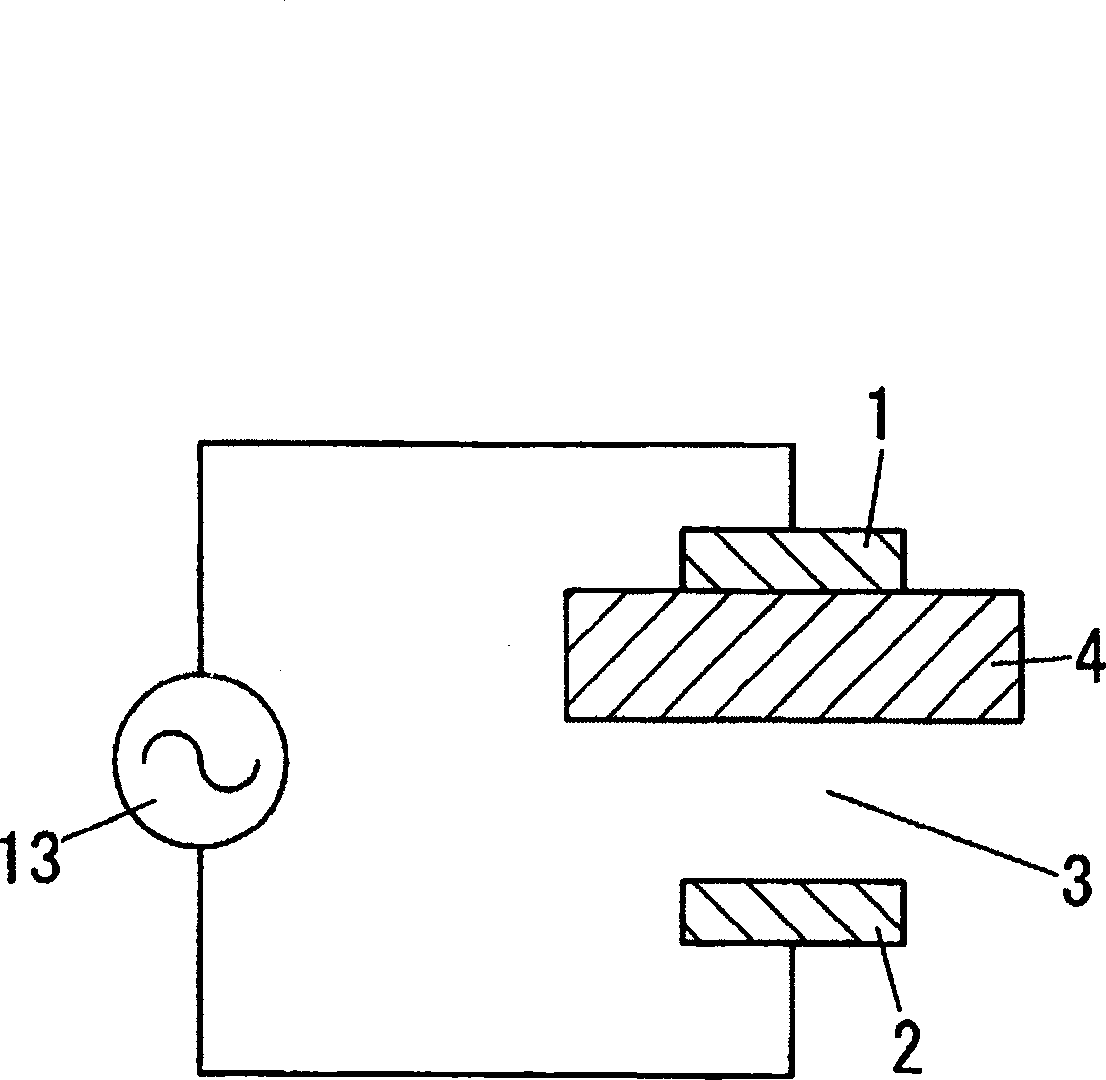

[0207] It is apparent from Table 4 that, compared with Example 4, the flow rate of plasma 5 increases due to the narrowing of the outlet 12 of the reactor 10, so that equivalent performance. However, when the voltage applied between the electrodes 1, 2 is increased to improve the plasma performance, as in Figure 12 In the reactor shown without the flange portion 6, a back discharge occurs outside the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com