Automatic thread-cutting device for cylindrical sewing machine

A sewing machine, straight type technology, applied in the sewing machine to cut off the thread mechanism, sewing machine components, sewing equipment, etc., can solve the problems of angle error, inconvenience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Relevant detailed description and technical contents of the present invention are as follows now in conjunction with the accompanying drawings:

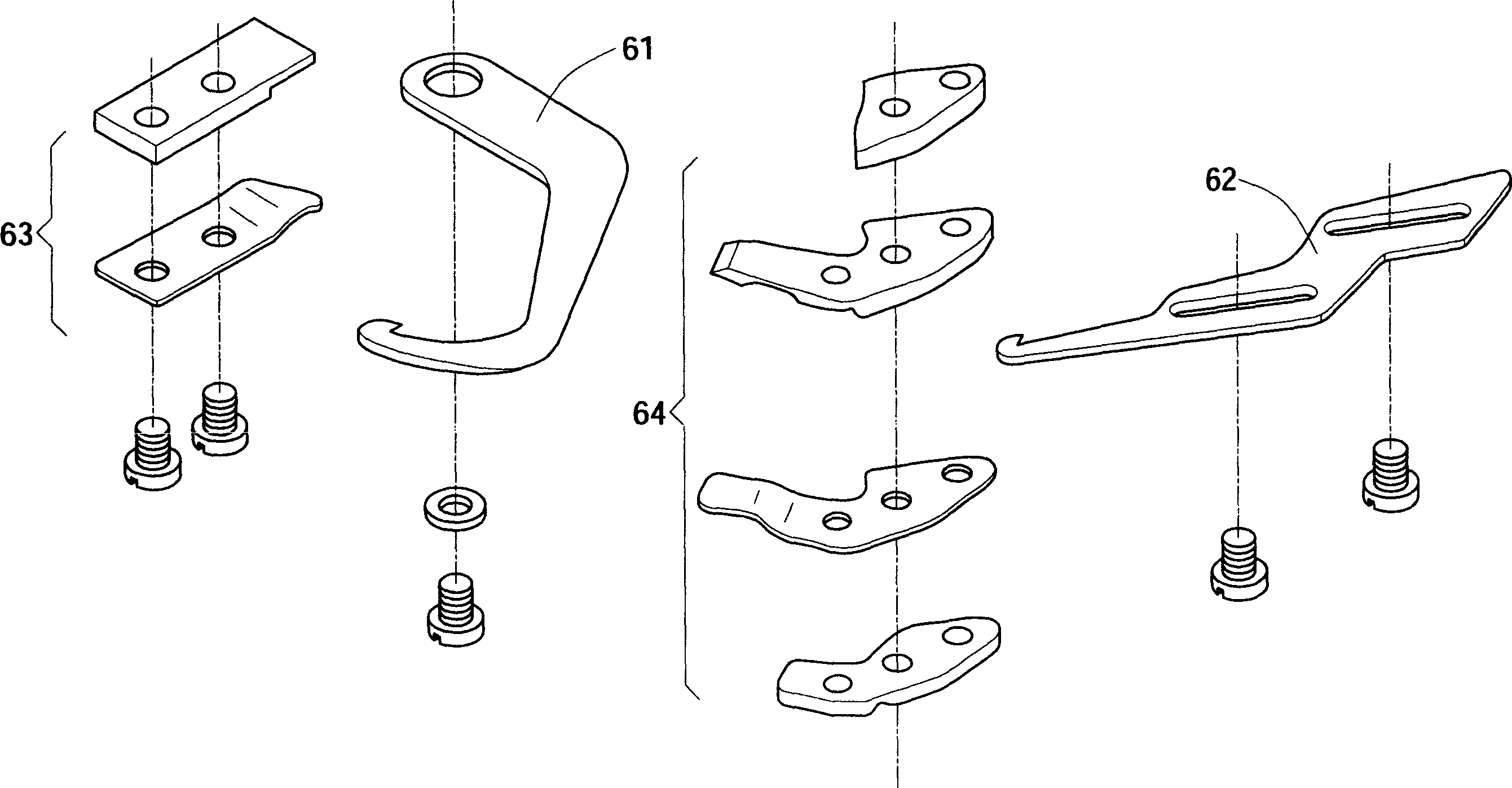

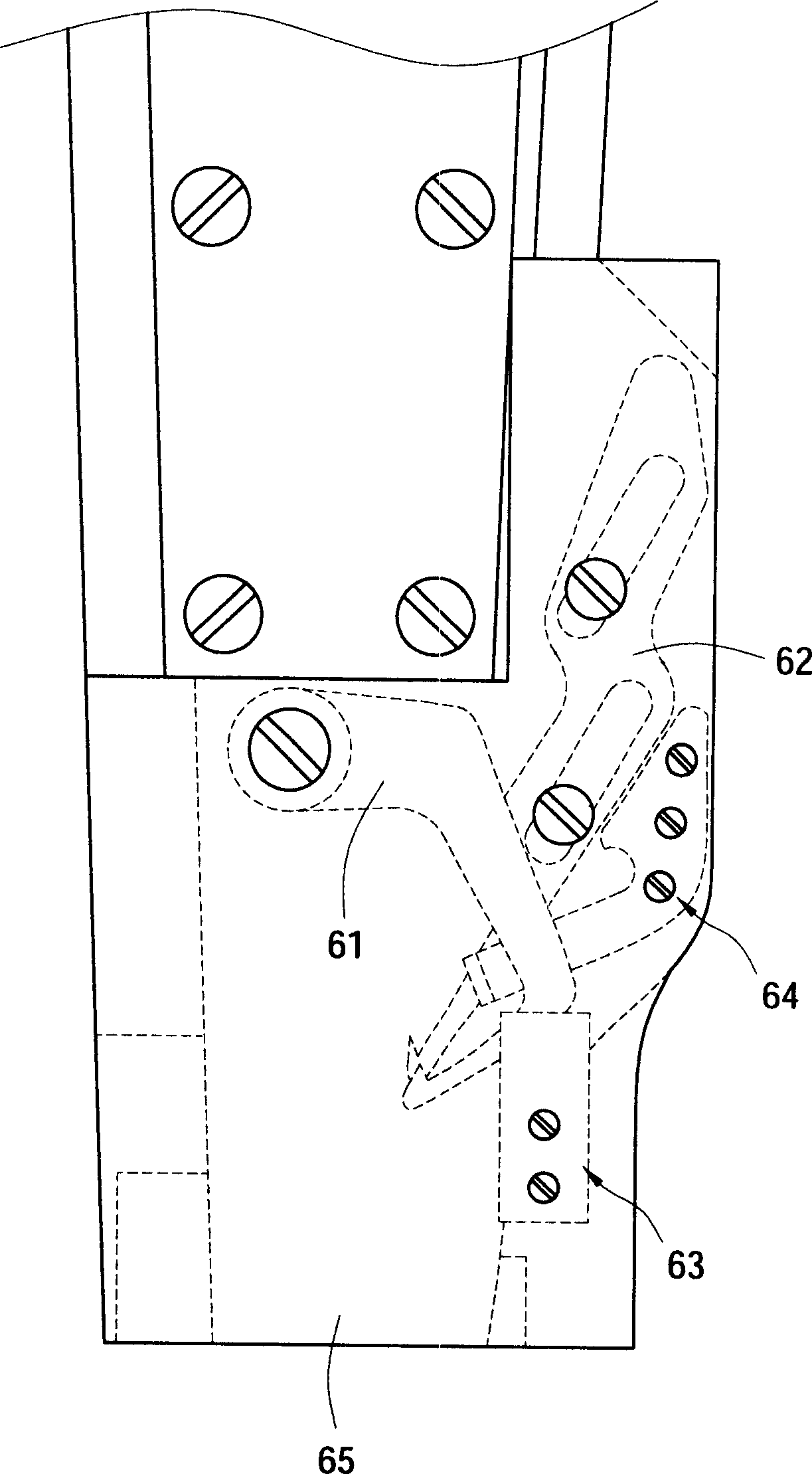

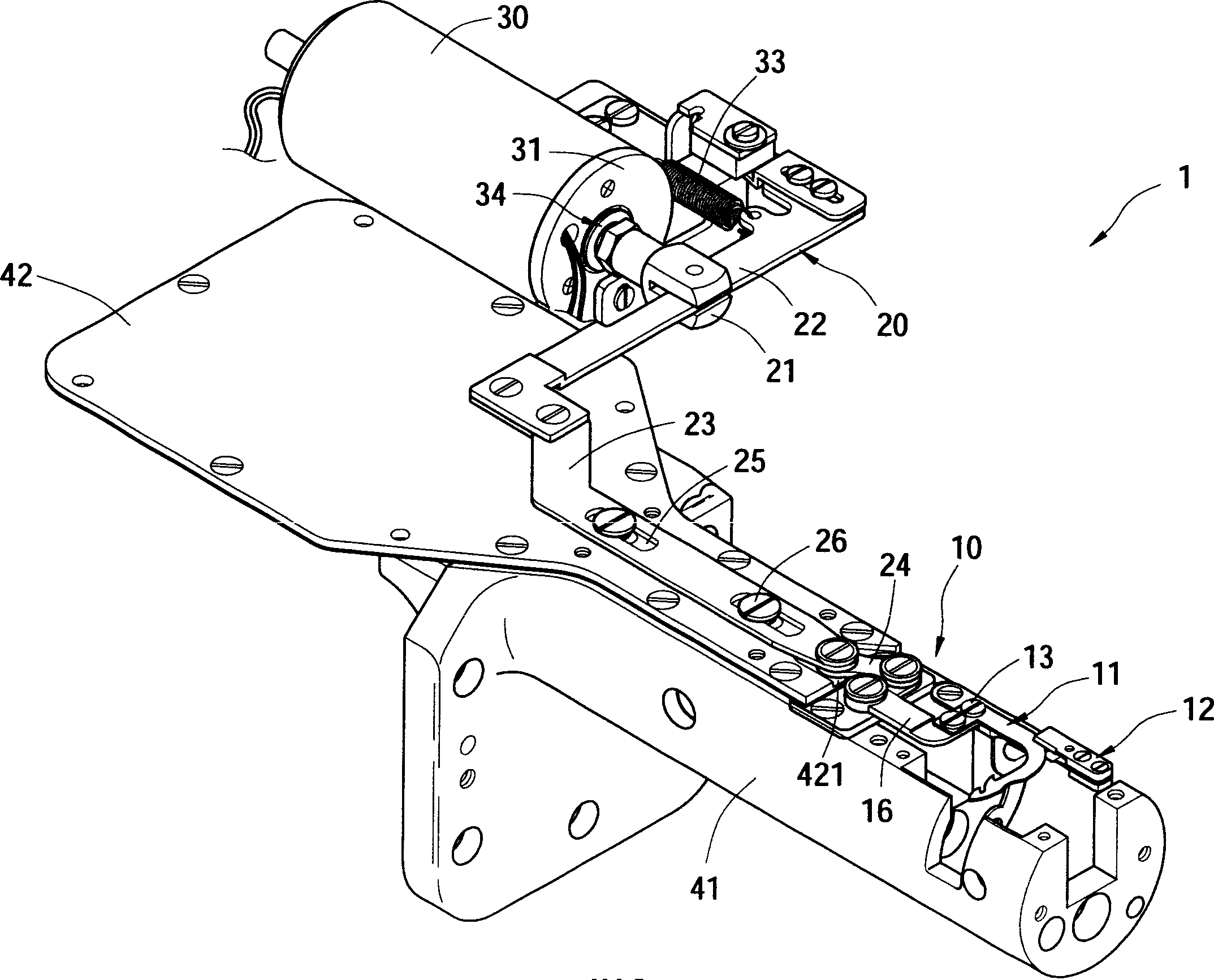

[0018] see image 3 , the automatic thread cutting device 1 includes a thread cutter 10, a linkage mechanism 20, and a driver 30, wherein the driver 30 is placed on a support portion 31 to provide power, and then drives the linkage mechanism 20 to move, and the linkage mechanism 20 Then link the thread cutter 10 to carry out the thread cutting action.

[0019] see Figure 4 , the driver 30 can provide a two-way electromagnet for the continuous two-way movement of the linkage mechanism 20, and then the yarn cutter 10 is linked to cut off the yarn 50, and the driver 30 is erected on the support part 31, with the action part 34 and the linkage mechanism The turning part 21 of 20 is connected, and the supporting part 31 is connected with the blocking plate 32, and the blocking plate 32 is used for connecting the elastic element ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com