Group III nitride crystal, method of its manufacture, and equipment for manufacturing group III nitride crystal

A technology of nitride crystals and equipment, applied in chemical instruments and methods, crystal growth, semiconductor/solid-state device manufacturing, etc., can solve problems such as slow growth rate of GaN crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

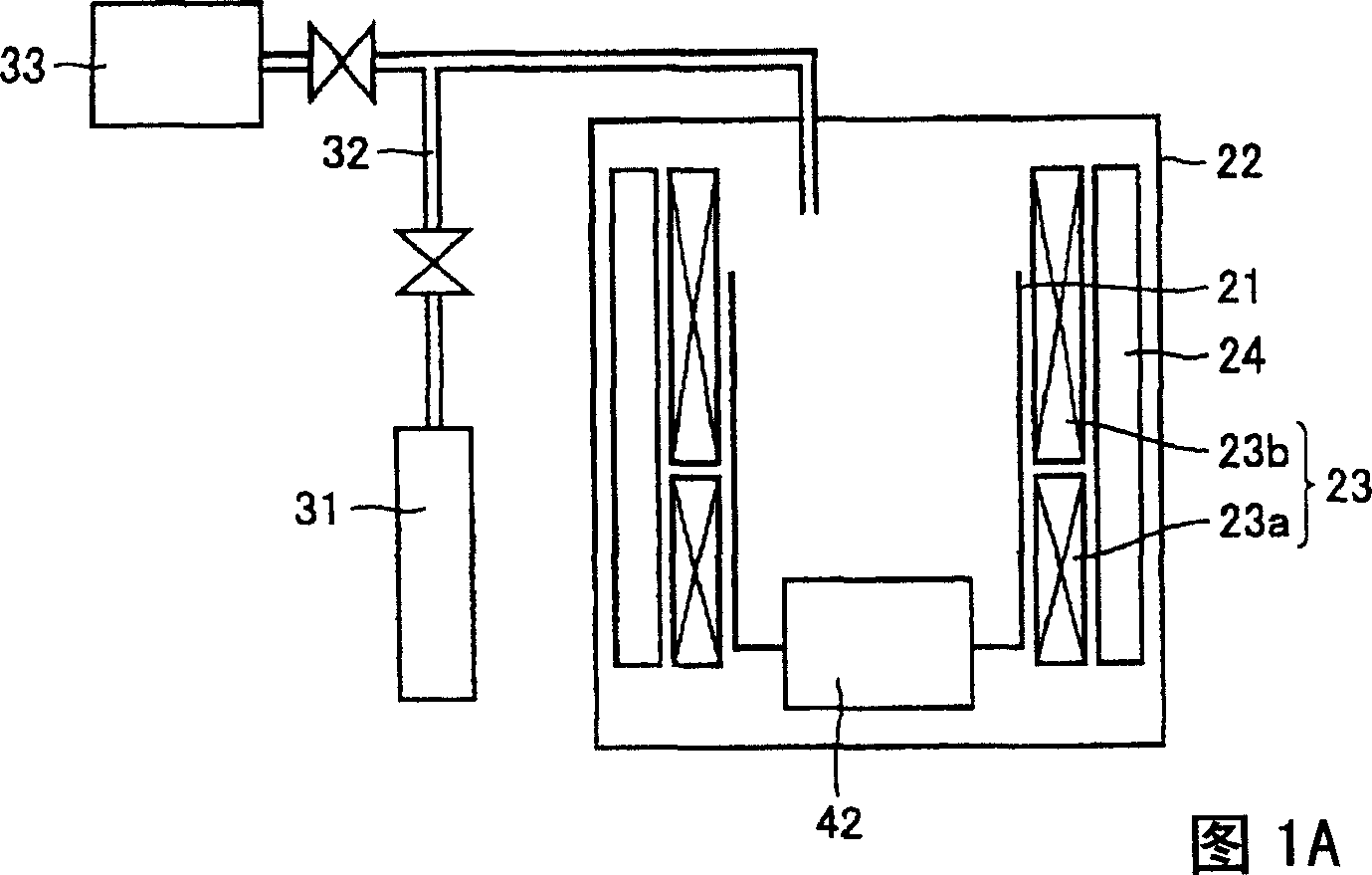

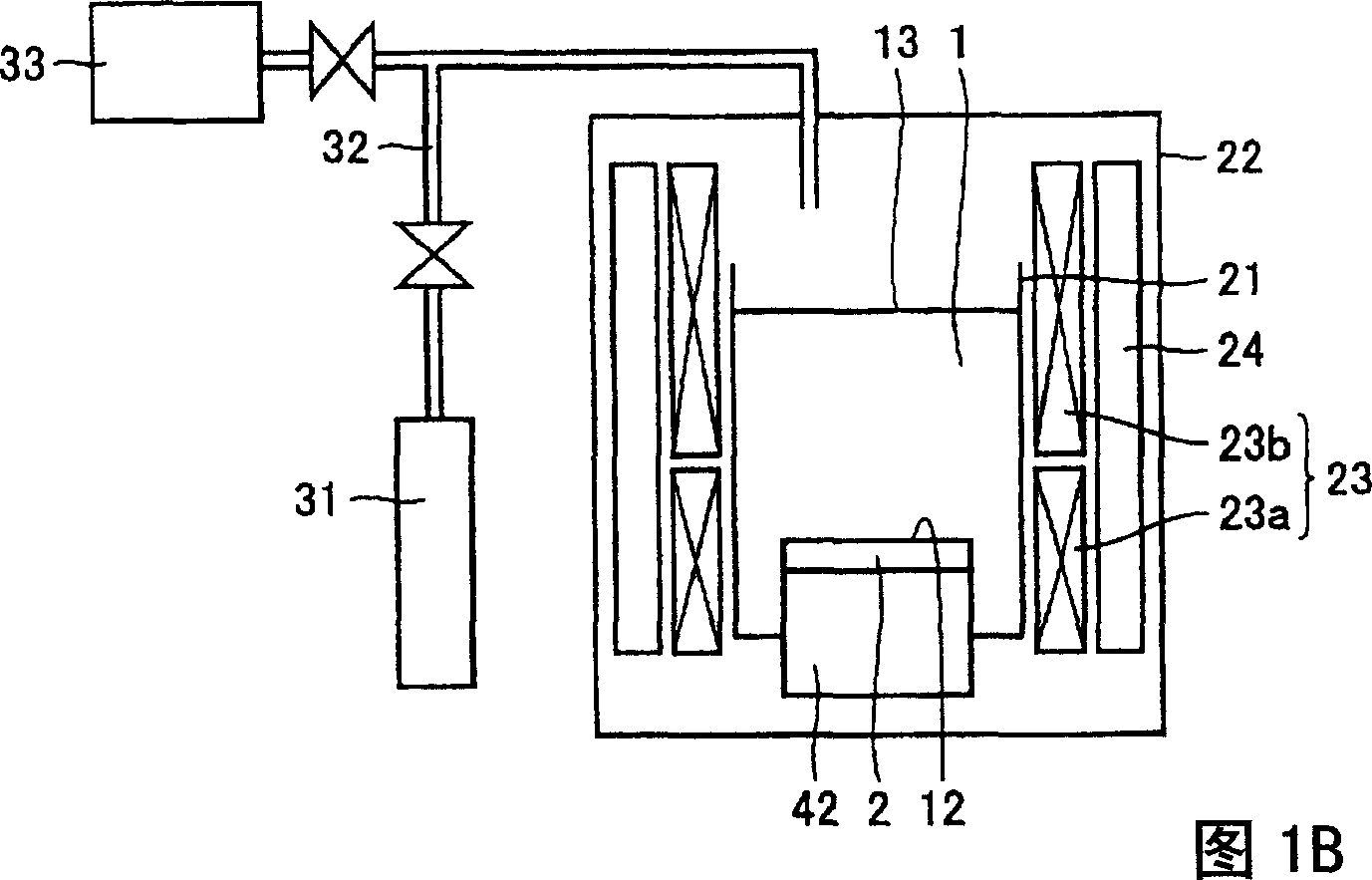

[0028] A method for preparing group III nitride crystals involved in the present invention is illustrated in FIG. 1 . In the production apparatus for this production method, at least one reaction vessel 21 is equipped in the outer vessel 22, heaters 23 (low temperature heater 23a and high temperature heater 23b) for heating the reaction vessel, and an insulating member 24, respectively Specifically, a nitrogen-containing substance supply device 31 and a nitrogen-containing substance supply line 32 for supplying the nitrogen-containing substance into the reaction vessel 21 are equipped.

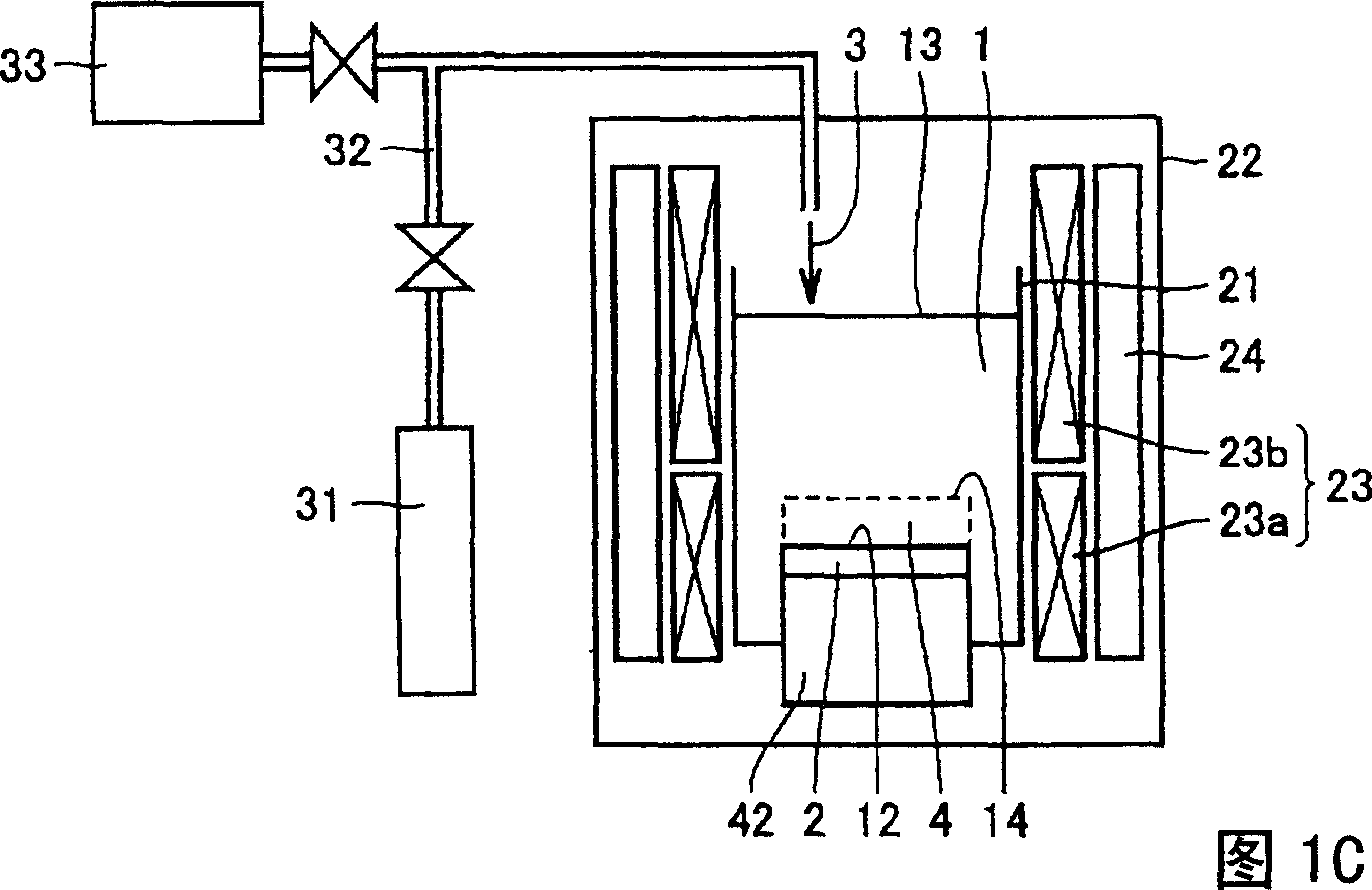

[0029]The method for preparing the Group III nitride crystals involved in the present invention comprises: referring to FIG. 1B , in a reaction vessel 21 , forming a melt 1 of a melt 1 comprising at least one Group III element and a catalyst around a seed crystal 2 . body forming step; and referring to FIG. 1C , a crystal growth step in which a nitrogen-containing substance 3 is supplied to th...

Embodiment approach 2

[0044] As shown in Figure 1, a kind of preparation equipment that the independent method that the present invention relates to preparation Group III nitride compound utilization utilizes comprises: at least one reaction vessel 21 that has opening in outer container 22, heater 23 and insulating member 24 , wherein the heater 23 and the insulating member 24 are made of graphite, wherein the method includes: as shown in FIG. 1B , in the reaction vessel 21, surrounding the seed crystal 2 to form A melt forming step of a melt 1 of one or more elements; and a crystal growth step of supplying a nitrogen-containing substance 3 to the melt 1 so as to grow a Group III nitride crystal 4 on the seed crystal 2, as shown in FIG. 1C . Utilizing small surface area materials such as graphite in the heater and insulation helps to control oxygen and / or water vapor that is primarily passed through the heater and insulation from dissolved in the Produced in the melt in the reaction vessel, it pro...

Embodiment approach 3

[0046]A separate method for preparing Group III nitride crystals according to the present invention includes, referring to FIG. 1 : the step of pretreating the reaction vessel by heating the reaction vessel 21 as shown in FIG. 1A to remove moisture; as shown in FIG. 1B In the reaction vessel 21 from which moisture has been removed, a melt forming step of forming a melt 1 comprising at least one or more elements selected from group III elements, alkali metal elements, and transition metals around the seed crystal 2; And a crystal growth step of supplying nitrogen-containing substance 3 to melt 1 to grow Group III nitride crystal 4 on seed crystal 2 as shown in FIG. 1C . Pretreatment of the reaction vessel 21 by heating the reaction vessel 21 to remove moisture reduces the dissolution of water vapor in the melt 1 and promotes the dissolution of nitrogen in the melt 1 thereby promoting the growth of Group III nitride crystals. Although in this respect, the conditions under which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com