Wafer positioning method and apparatus, processing system, and method for positioning wafer seat rotating axis of wafer positioning apparatus

A technology of positioning device and positioning method, which is applied to measurement devices, optical devices, instruments, etc., can solve problems such as low positioning accuracy, and achieve the effects of high wafer positioning, high precision, and shortening operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

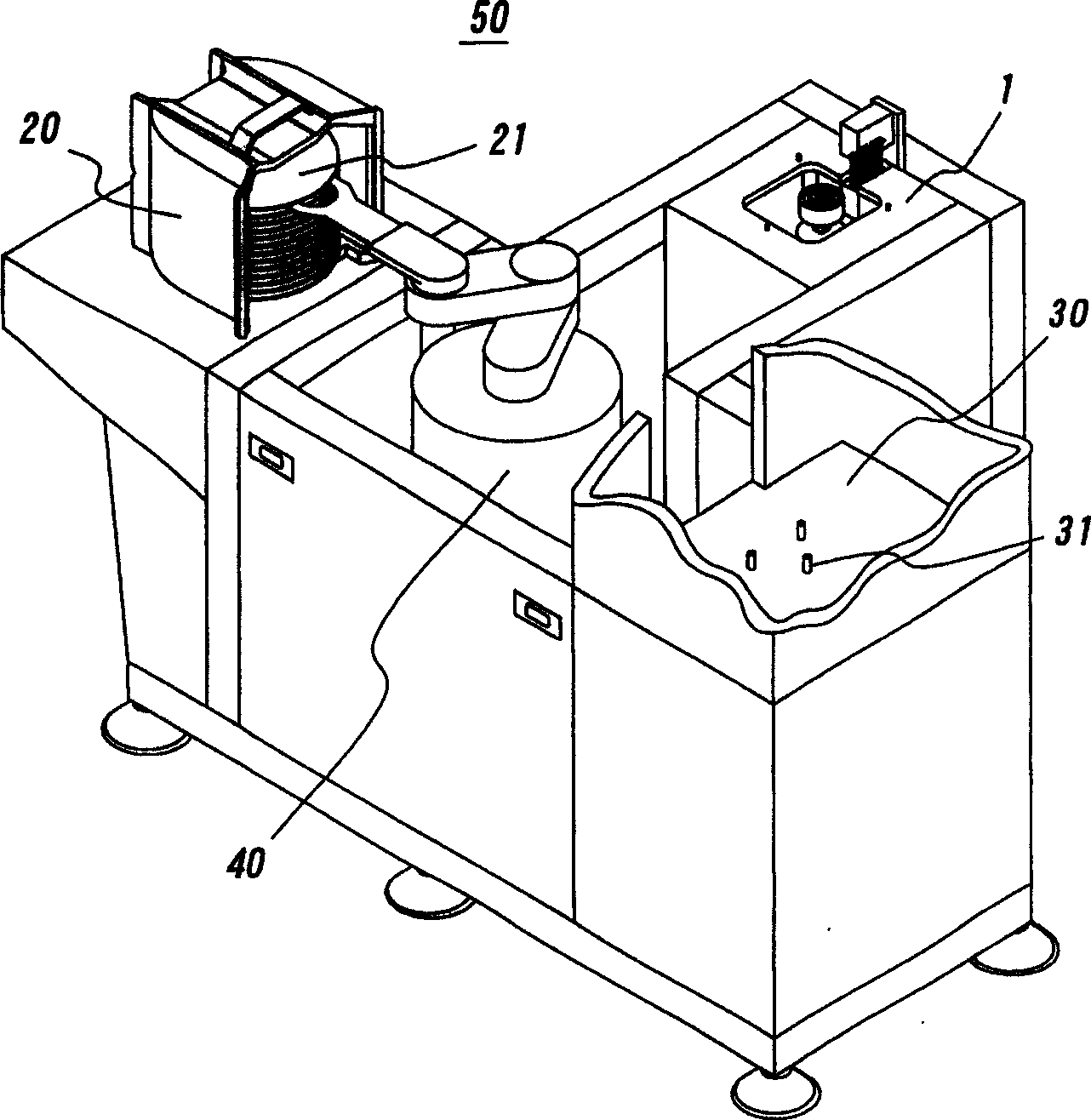

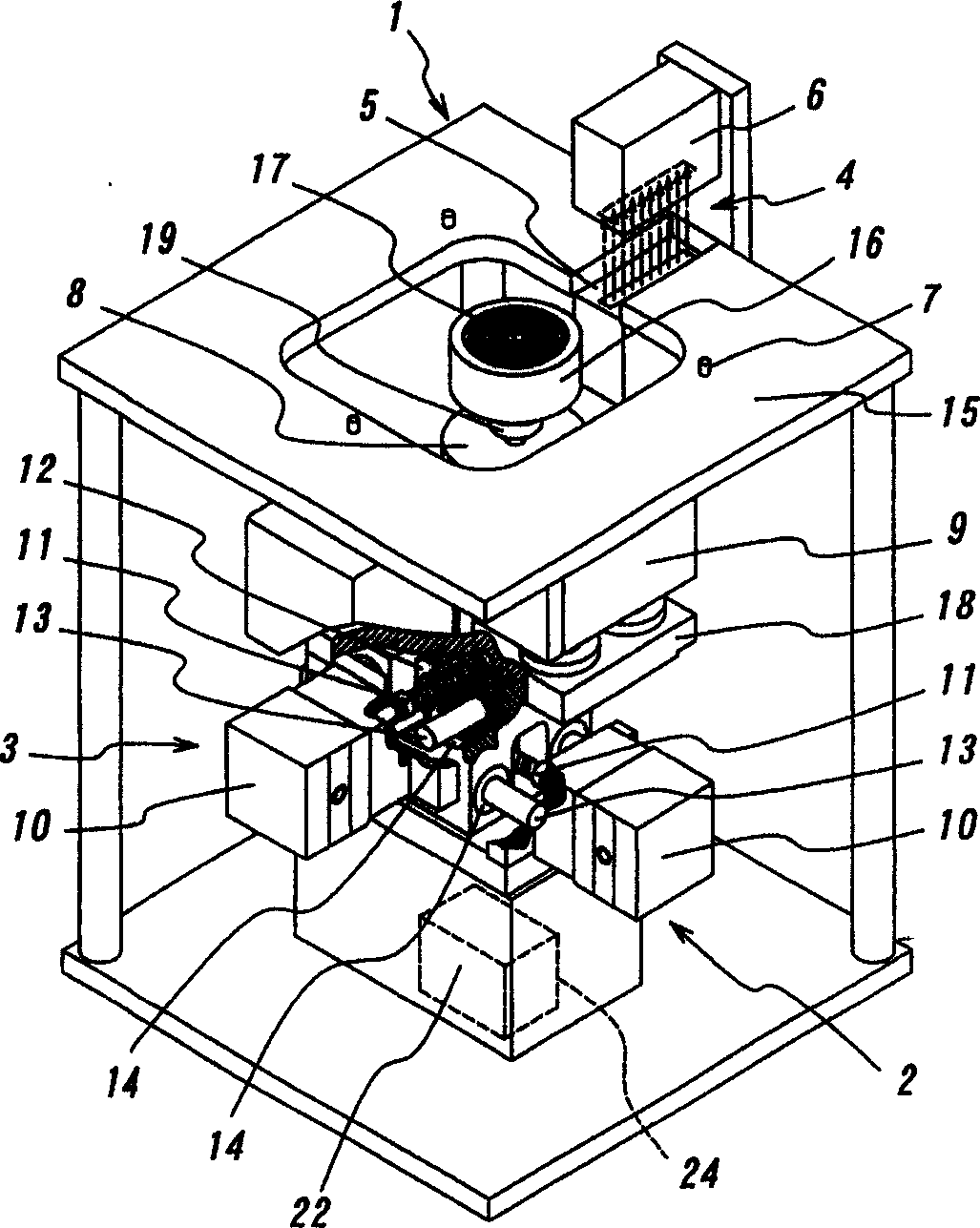

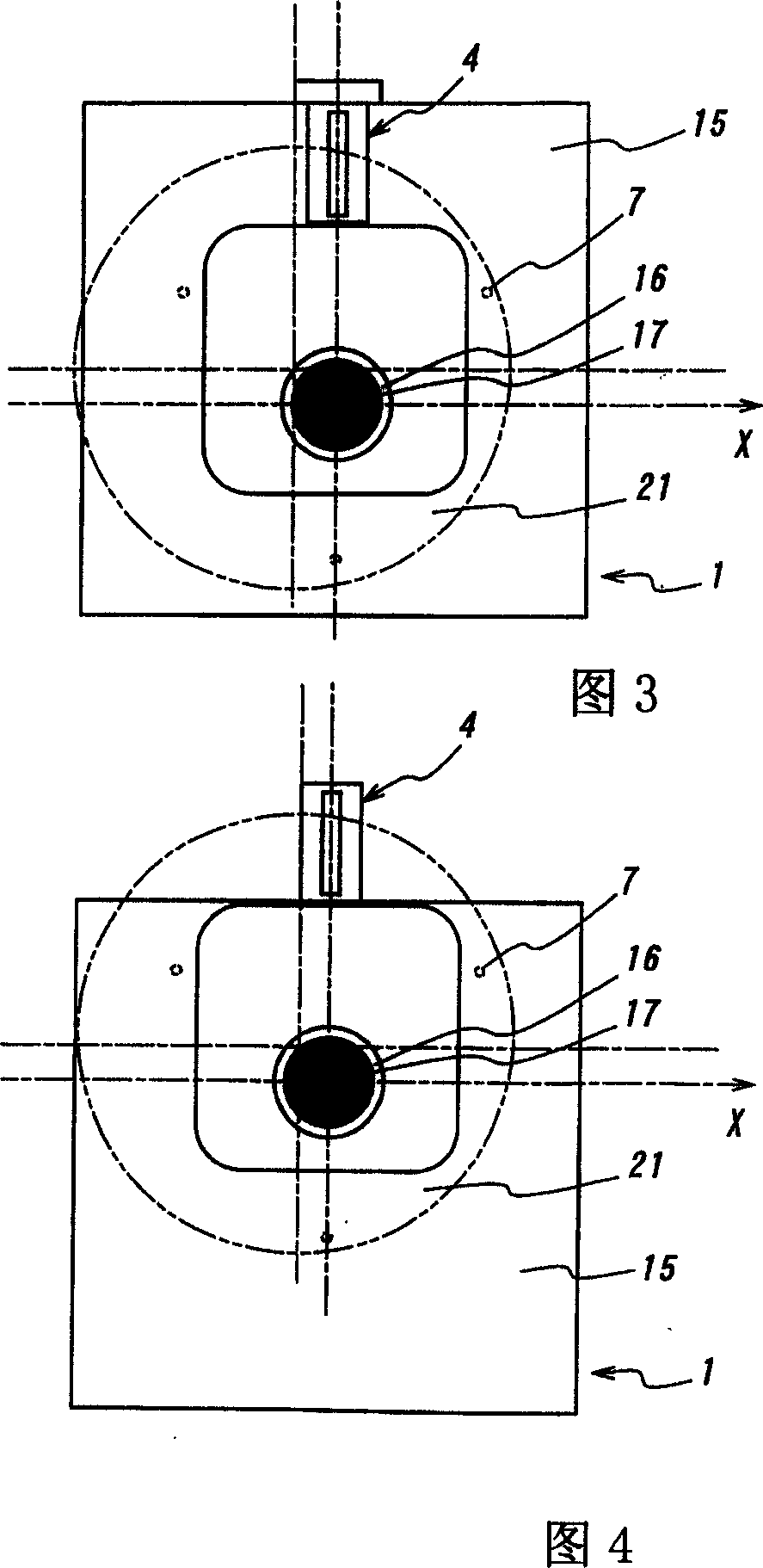

[0087] Hereinafter, an embodiment of the present invention will be described in detail by way of example based on the drawings. figure 1 is a perspective view, partially in section, of a wafer processing system including an embodiment of the wafer positioning apparatus of the present invention utilizing an embodiment of the wafer processing method of the present invention. Such as figure 1 As shown, the wafer positioning apparatus 1 is placed next to a conventional wafer transfer apparatus 40 constituted by an industrial robot or the like and a conventional wafer processing apparatus 30 for performing etching processing etc. on a wafer. The wafer positioning device 1 , the wafer transfer device 40 and the wafer processing device 30 constitute a wafer processing system 50 , which is an embodiment of the wafer processing system of the present invention. When the wafer 21 is transferred to the wafer processing device 30 by the wafer transfer device 40 from the wafer cassette 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com