Winded fabrics testing device

A technology of textile and rolling inspection machine, which is applied in the direction of textile and papermaking, textile material inspection, winding strips, etc., which can solve the problems of operator's hand injury, waste of time, increase of work space, etc., to ensure normal and stable The effect of using, reducing manufacturing cost, and saving work space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

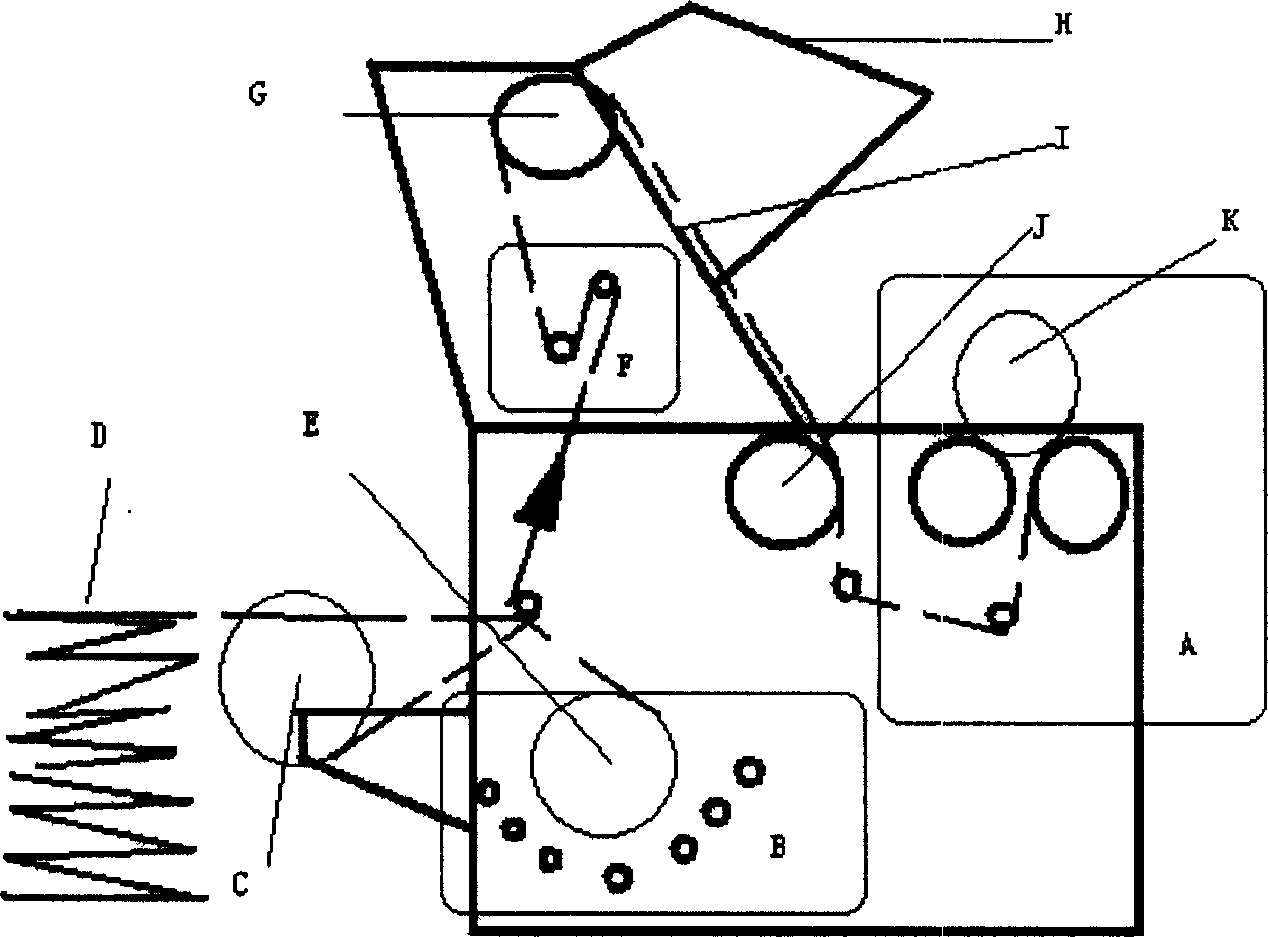

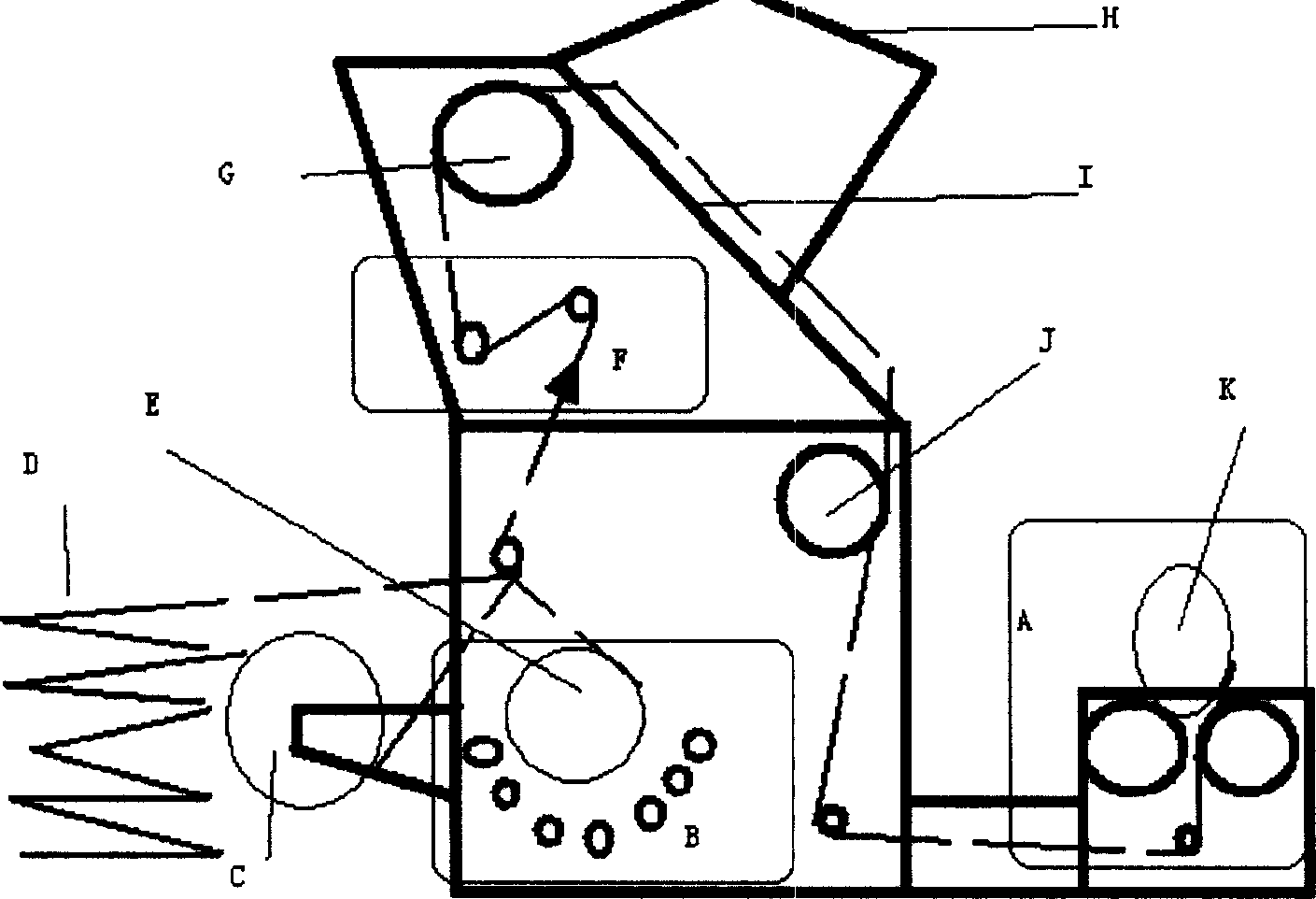

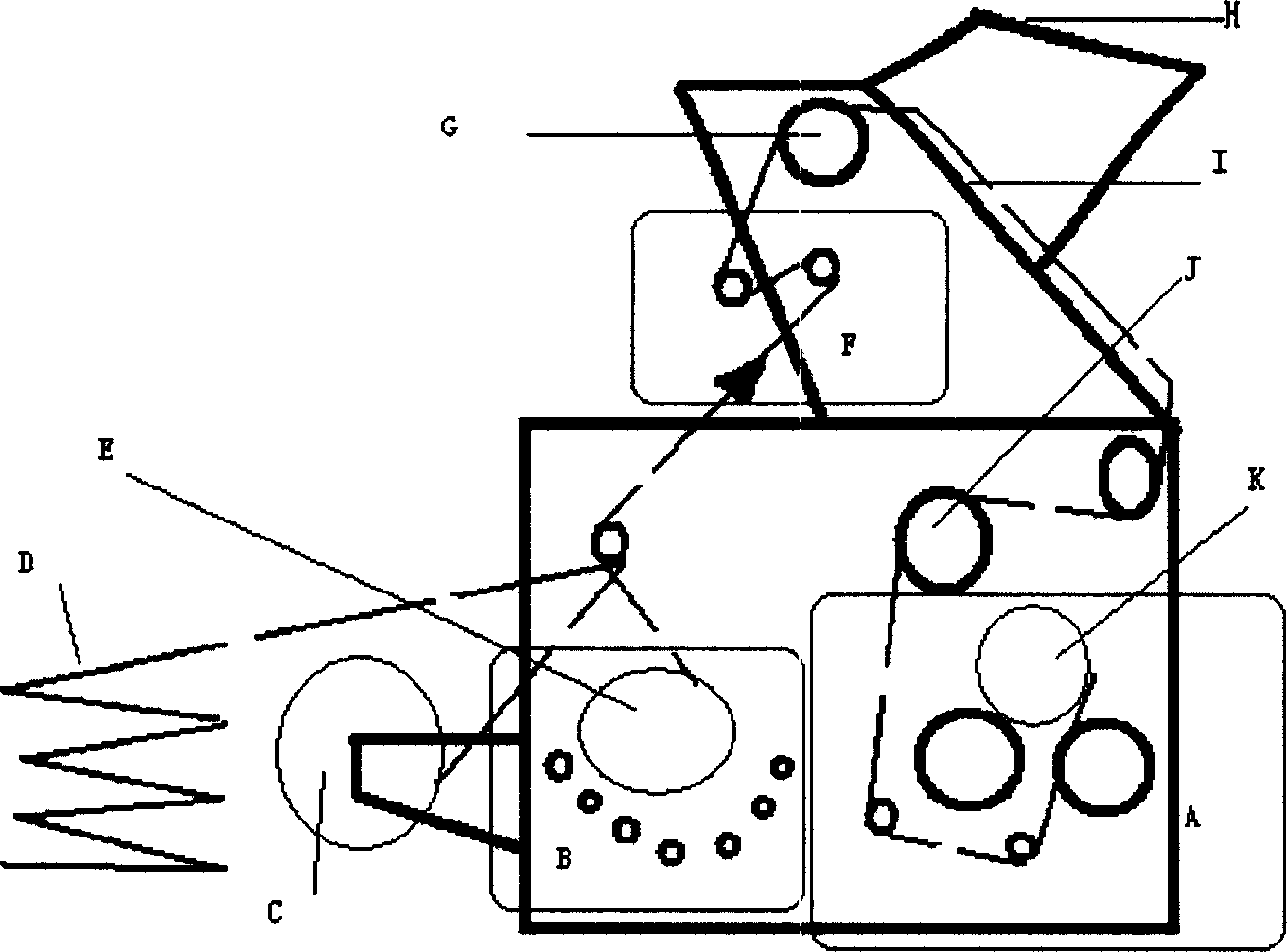

[0064] Two kinds of textile rolling inspection machines implementing the technical solution of the present invention, a kind of as shown in the accompanying drawing 3 of the description, the key is to implement the A part (the winding device with the infrared ray detection edge and the left and right moving side-aligning dolly) installed in the I part ( The other is shown in Figure 4 of the instruction manual, the key is to implement the L part (without infrared detection edge, the winding device that moves the side-aligning trolley left and right) installed in the I part ( Tilt the bottom of the translucent cloth inspection panel). The left and right sides of the two machines adopt the overall chassis structure, and the components including the motor, frequency converter, transmission chain, transmission belt, electromagnetic brake device, etc. that are easy to be polluted by dust and cause failure are installed in the overall chassis on both sides, which can effectively guara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com