One-way rotary plug valve

A plug valve and functional technology, applied in the field of plug valves, can solve the problems of cumbersome assembly, maintenance and inspection operations, large size, complex structure, etc., and achieve the effect of size reduction, performance improvement, and good actual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Hereinafter, embodiments of the present invention are described based on the drawings.

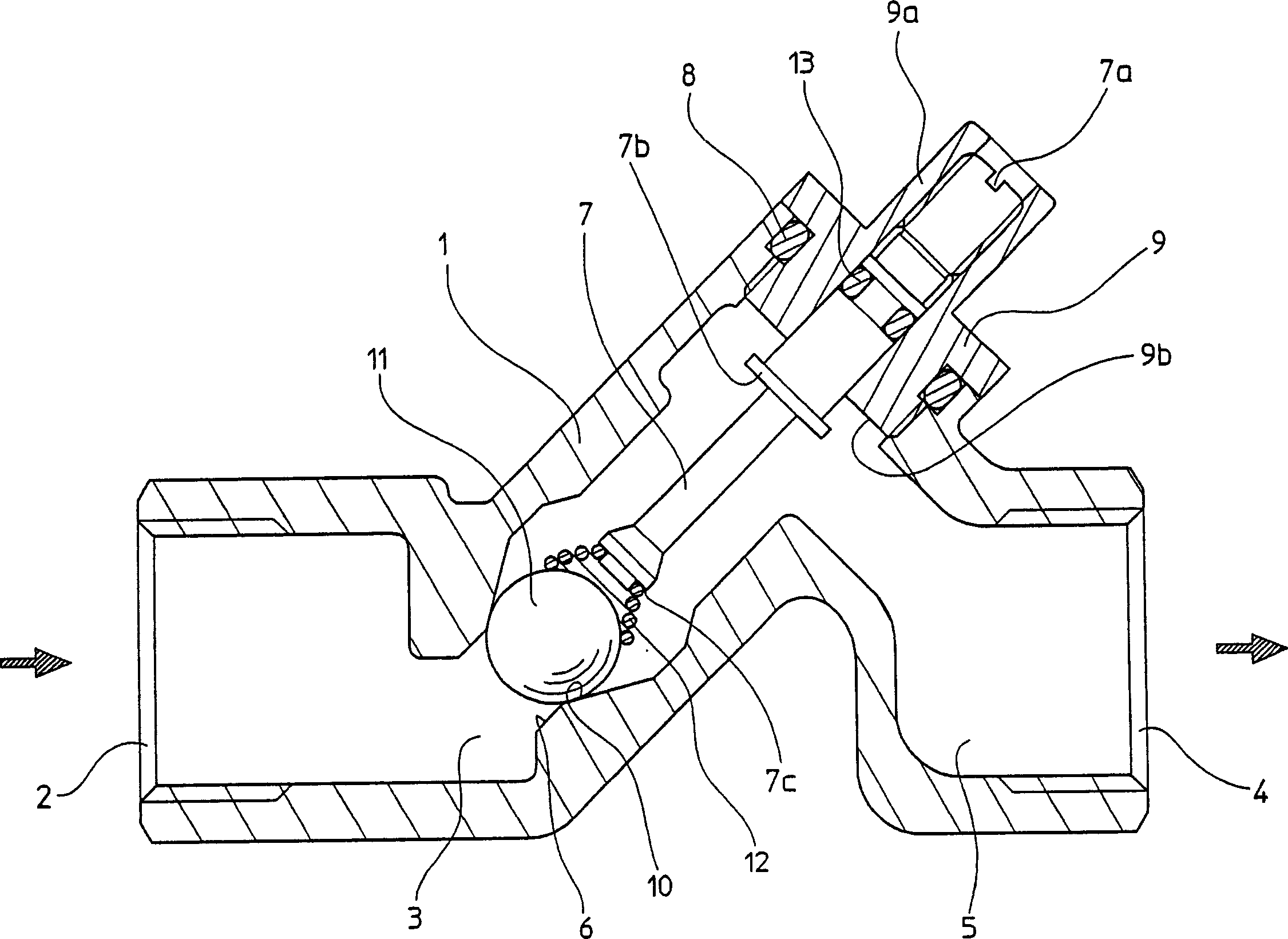

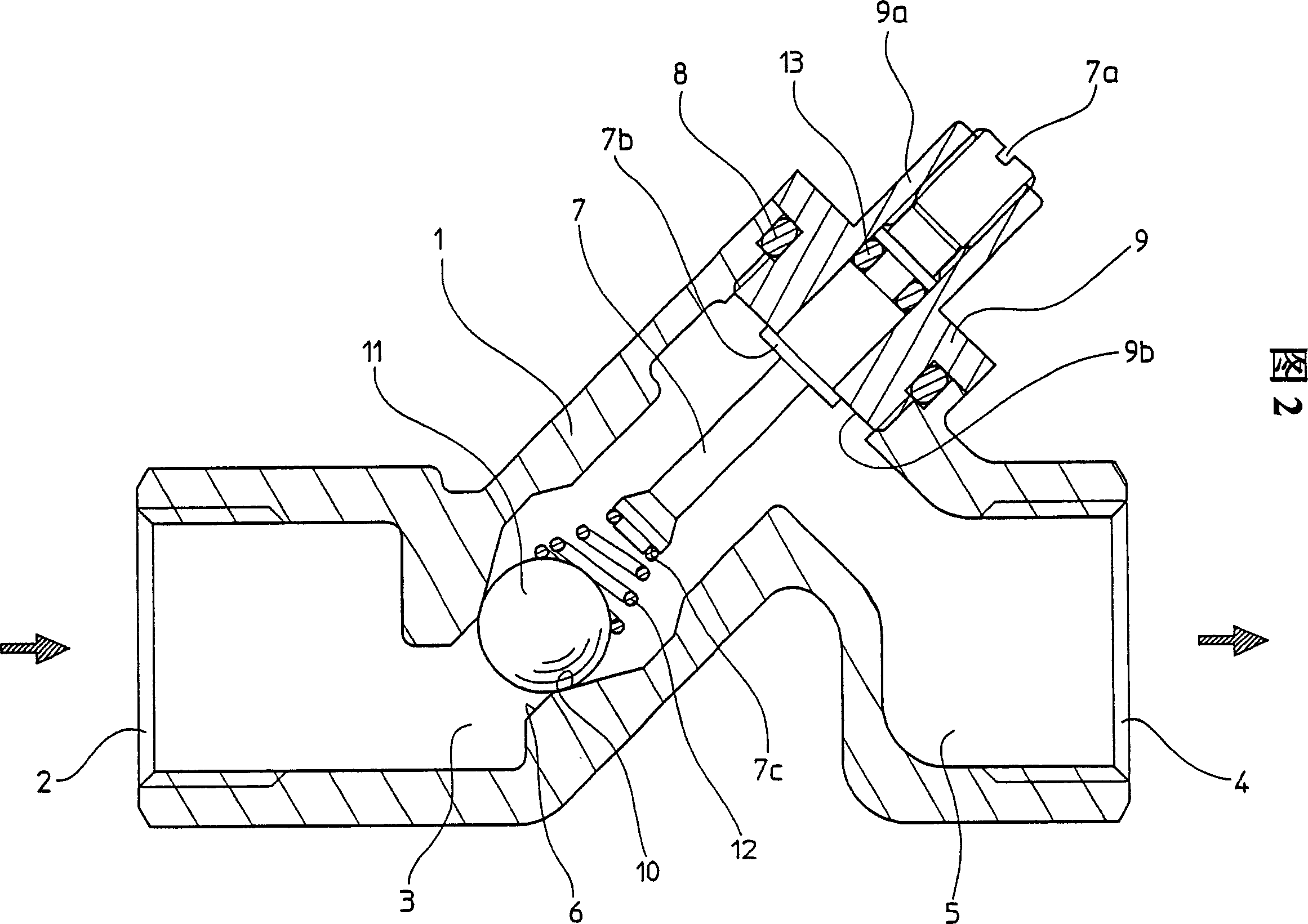

[0015] figure 1 and 2 are longitudinal sectional views of a plug valve with check function. Specifically, figure 1 A state where water is cut off is shown, while FIG. 2 shows a state where water is cut off when backflow has occurred.

[0016] The valve housing 1 of the plug valve is formed into a so-called Y shape, in which the center line of the flow path 3 (located on the primary side) of the inlet 2 communicating with the water supply source side and the flow path 5 of the outlet 4 communicating with the drain side (located on the secondary side) is on the same straight line, and the axis extending toward the secondary side of the valve port 6 for communicating between the primary side flow path 3 and the secondary side flow path 5 and the secondary side The flow path 5 forms an acute angle.

[0017] The upper portion of the valve sleeve 1 is formed in a substantially cylindr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com