Metal boride catalyst with high activity to hydrogen and its preparing method

A metal boride, high-activity technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as high price, achieve rapid reaction, strong operability, simple and convenient processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Take 3mol / l CoCl 2 100ml of the solution was placed in a flask, and then 200ml of 5% NaBH 4 The solution was added to the flask; the solution in the flask was mechanically stirred during this process. After the reaction, the mechanical stirring was stopped, and the suspension was separated into layers. Remove the supernatant; take out the lower precipitate, wash with deionized water, and filter until AgNO is added dropwise to the eluate. 3 The solution no longer produces a white precipitate. The above suction-filtered precipitate was vacuum-dried at 50° C. for 72 hours to obtain an amorphous product. The chemical composition of the obtained metal boride is Co 2.49 b.

[0021] In order to detect the dehydrogenation activity of metal borides, a certain amount of NaBH 4 The solution is placed in the reactor, and then a certain amount of the above-mentioned metal borides are added to the reactor, and NaBH 4 The solutions are in full contact; the hydrogen gas produced...

Embodiment 2

[0023] Take 5mol / l CoCl 2 Solution 100ml, placed in a flask, then 500ml concentration of 5% NaBH 4 The solution was added to the flask; the solution in the flask was sonicated during this process. After the reaction, the ultrasonic oscillation was stopped to separate the layers of the suspension. Remove the supernatant; take out the lower precipitate, wash with deionized water, and filter until AgNO is added dropwise to the eluate. 3 The solution no longer produces a white precipitate. The above suction-filtered precipitate was vacuum-dried at 160° C. for 72 hours to obtain an amorphous product. The chemical composition of the obtained metal boride is Co 2.08 b.

[0024] The dehydrogenation activity of the metal boride was detected by the method described in Example 1, and the dehydrogenation efficiency of the above metal boride was measured to be 95%.

Embodiment 3

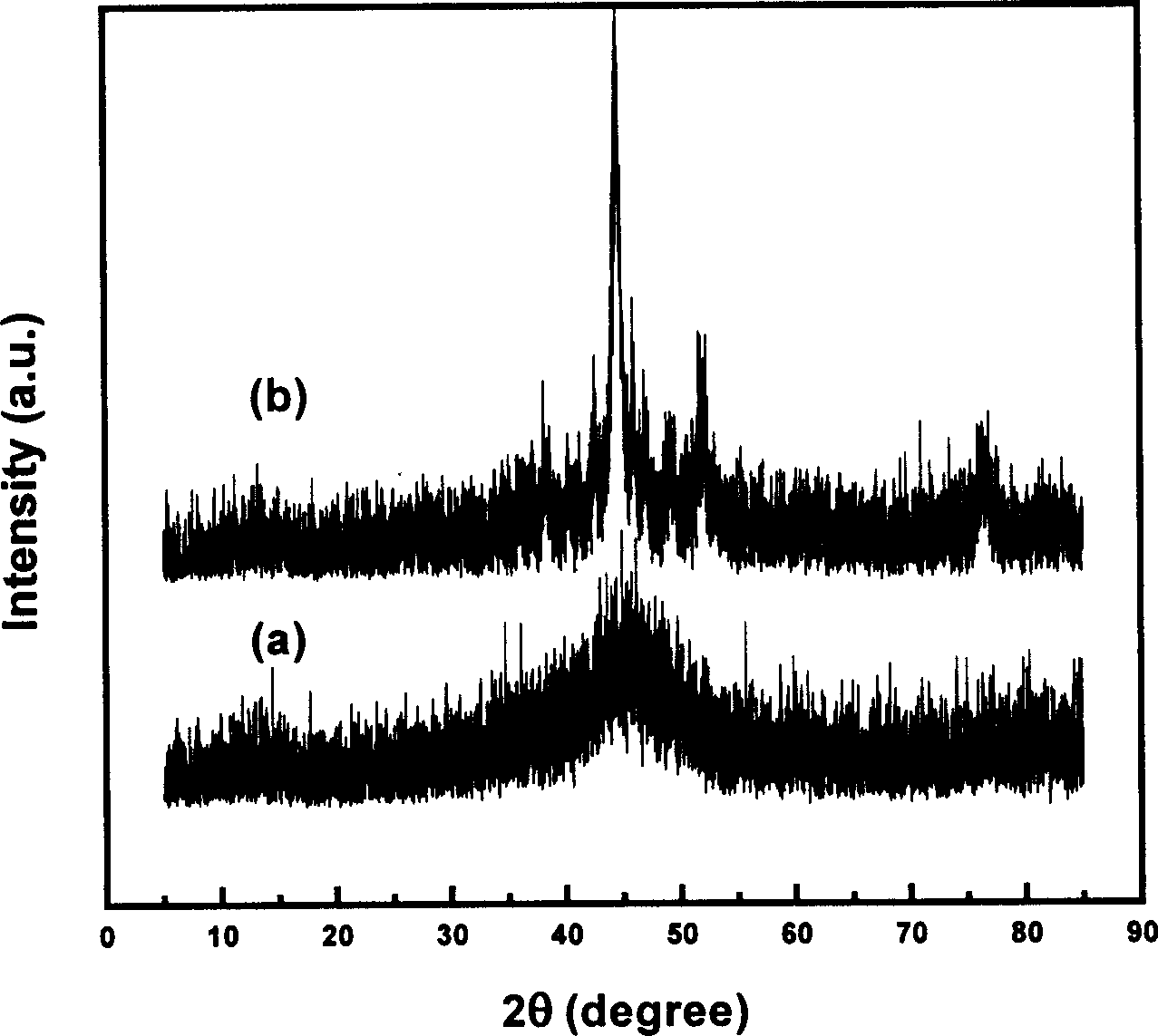

[0026] Take 8mol / l NiCl 2 Solution 150ml, placed in a flask, then 500ml concentration of 10% NaBH 4 The solution was added to the flask; the solution in the flask was mechanically stirred during this process. After the reaction, the mechanical stirring was stopped, and the suspension was separated into layers. Remove the supernatant; take out the lower precipitate, wash with deionized water, and filter until AgNO is added dropwise to the eluate. 3 The solution no longer produces a white precipitate. The above suction-filtered precipitate was vacuum-dried at 90° C. for 84 hours to obtain an amorphous product, whose X-ray diffraction spectrum is shown in curve (a) in the accompanying drawing.

[0027] The dehydrogenation activity of the metal boride was detected by the method described in Example 1, and the dehydrogenation efficiency of the above metal boride was measured to be 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com