Microwave measuring device for detecting the charge of a two-phase flow

A microwave measurement and fluid technology, which is used in measurement devices, liquid/fluid solid measurement, and material analysis using microwave methods, can solve problems such as complex installation, insufficient measurement accuracy, and air flow conditions, and achieve economical structure and measurement results. Accurate, Simple Cost Results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

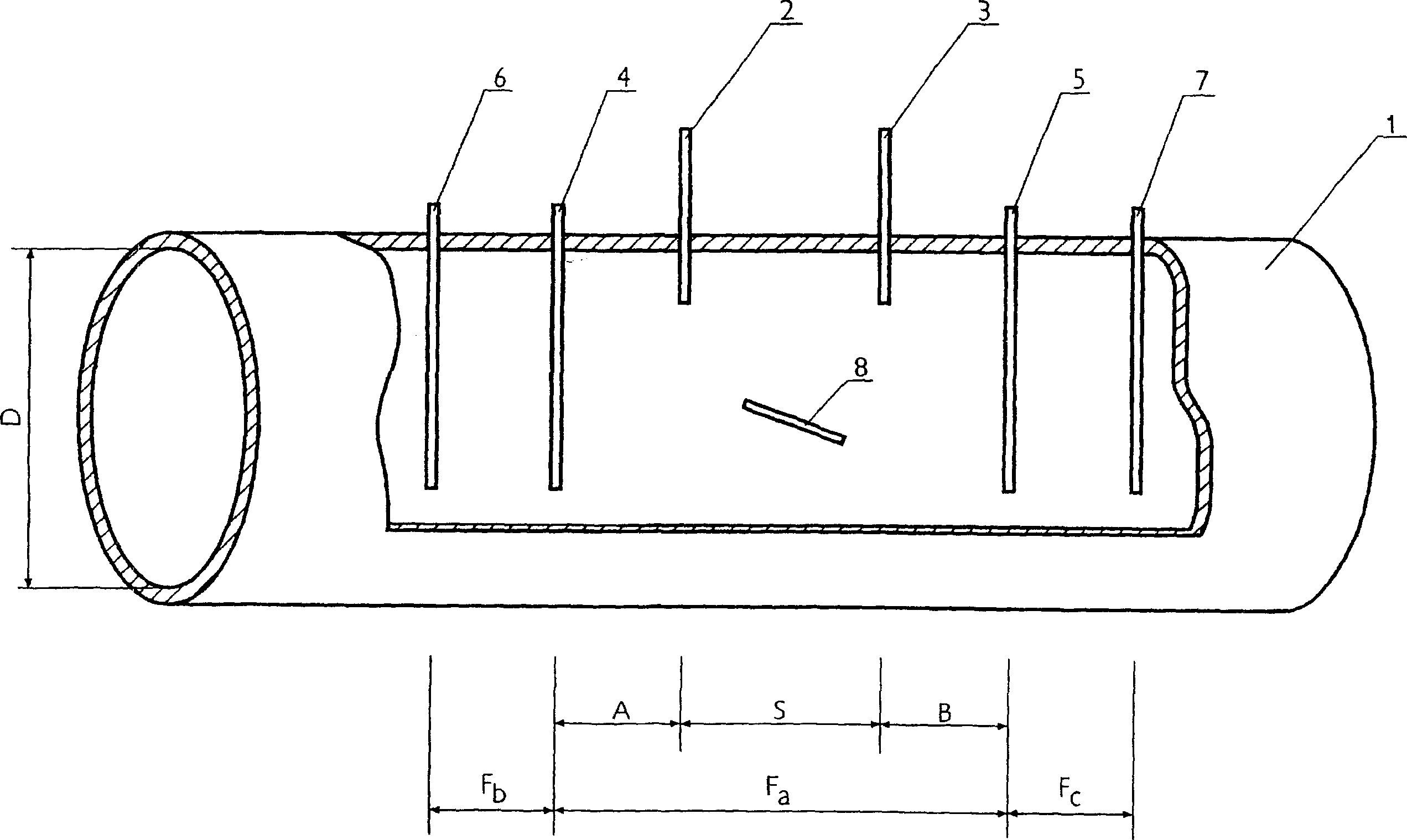

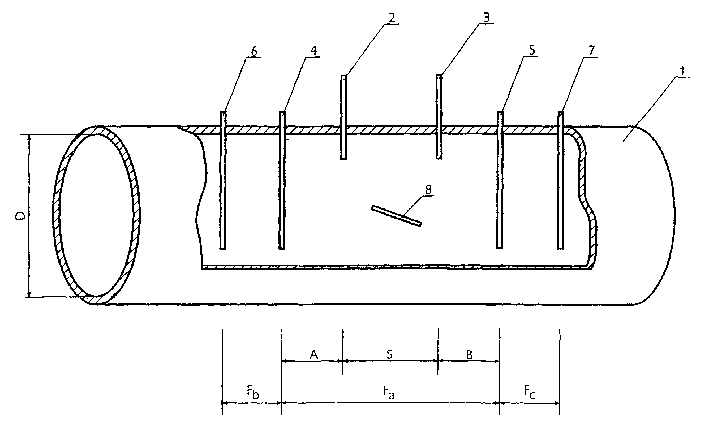

[0021]The figure depicts a section of a feed line 1 for pneumatically conveying pulverized coal in a partially cutaway manner. The feed pipe 1 is of the type usually used in pulverized coal fired furnaces in power stations. The feed pipe 1 is made of corrosion-resistant steel. It has an approximately circular cross-section with a diameter D=200mm. The transmitting antenna 2 and the receiving antenna 3 extend from the outside into the feeding pipe, are installed continuously at intervals of 300 mm in the longitudinal direction of the feeding pipe, and form a measuring path S. Microwaves with a frequency between 840 and 860 MHz are coupled through the transmission antenna 2 . These microwaves correspond to the waveguide fundamentals of the feed pipe 1 . Along the longitudinal direction of the feeding pipe 1, in front of the transmission antenna 2 and behind the receiving antenna 3, in the polarization plane of the input microwave, there are field rods 4 and 5 extending radial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com