Super slide wear resistance safety tyre

A safety tire, super technology, applied in tire parts, tire tread/tread pattern, transportation and packaging, etc., can solve problems such as long start-up time of brake anti-skid devices, damage to the road surface of anti-skid tires, and inappropriate movements. The ability to prevent traffic accidents, the effect of quick start and quick acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

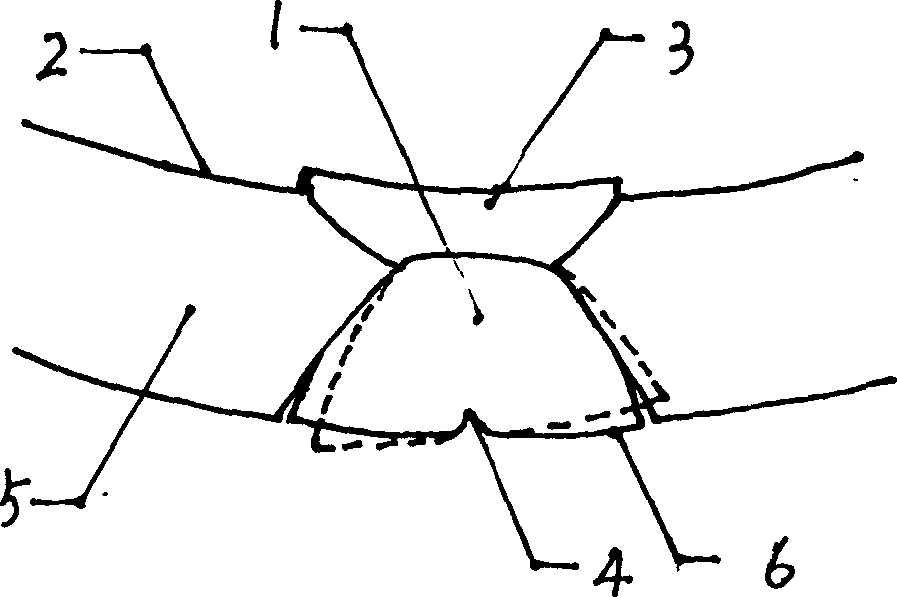

[0031] Such as figure 1 As shown, a layer of steel cords (2) is arranged slightly inwardly in the depression of the outer tread, the module (1) is inverted in a bowl shape, the bottom surface (3) is connected with the steel cords (2), and the bowl surface (6) According to needs with outer tire profile or protruding, concave, overlap. Small anti-skid lines (4) are set on the bowl surface, and most of the bowl side can be provided with protrusions to be connected with the tire rubber (5), and the outward part of the outer tread depression is not connected or flexibly connected to the outside of the bowl side of the module (1).

specific Embodiment approach 2

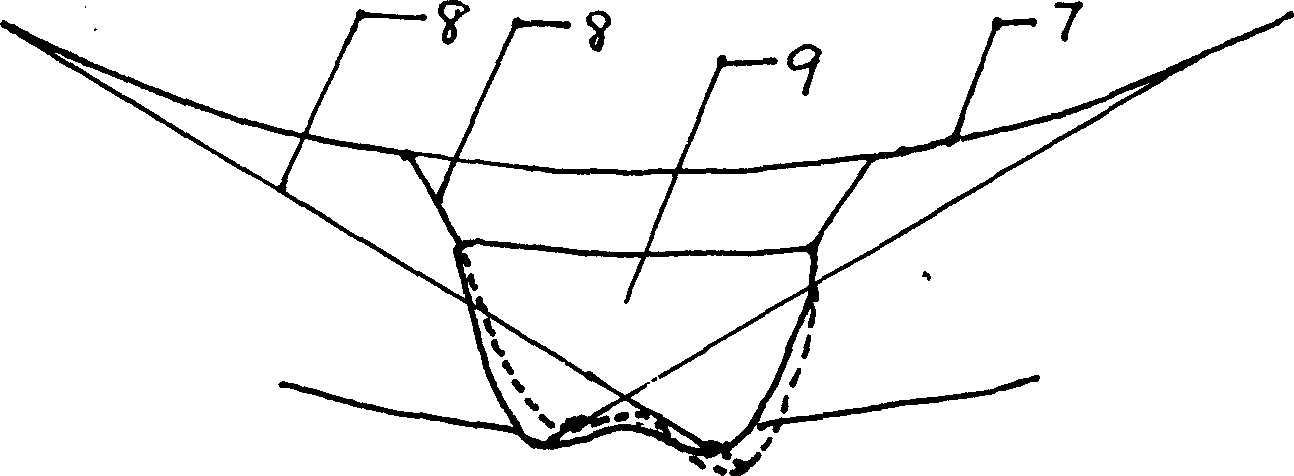

[0032] Such as figure 2 As shown, the thin tough wire (8) is connected with the cord (7), and after the shallow groove (9) is bonded with a flexible material, it slightly protrudes from the outer contour of the tire.

specific Embodiment approach 3

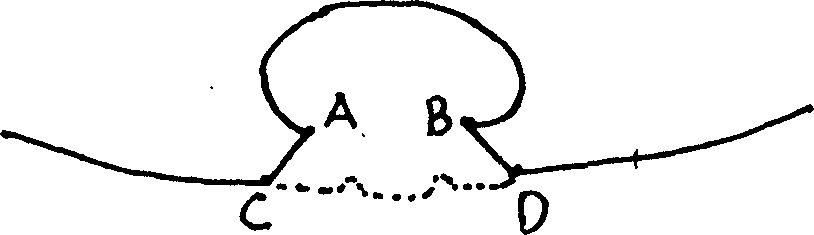

[0033] Such as image 3 As shown, the outer tire is provided with an open Ω-shaped groove, and the superglue is applied from A to B, and the module is pressed in, or A to C, B to D is coated with flexible glue or a cushion, and the module is used The gel is injected into the groove, and it can be used after setting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com