Method and system for monitoring etch process

A process system and etching technology, which can be used in photoengraving process exposure device, pattern surface photoengraving process, microlithography exposure equipment, etc., can solve the problem of reducing the dimensional accuracy of components and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

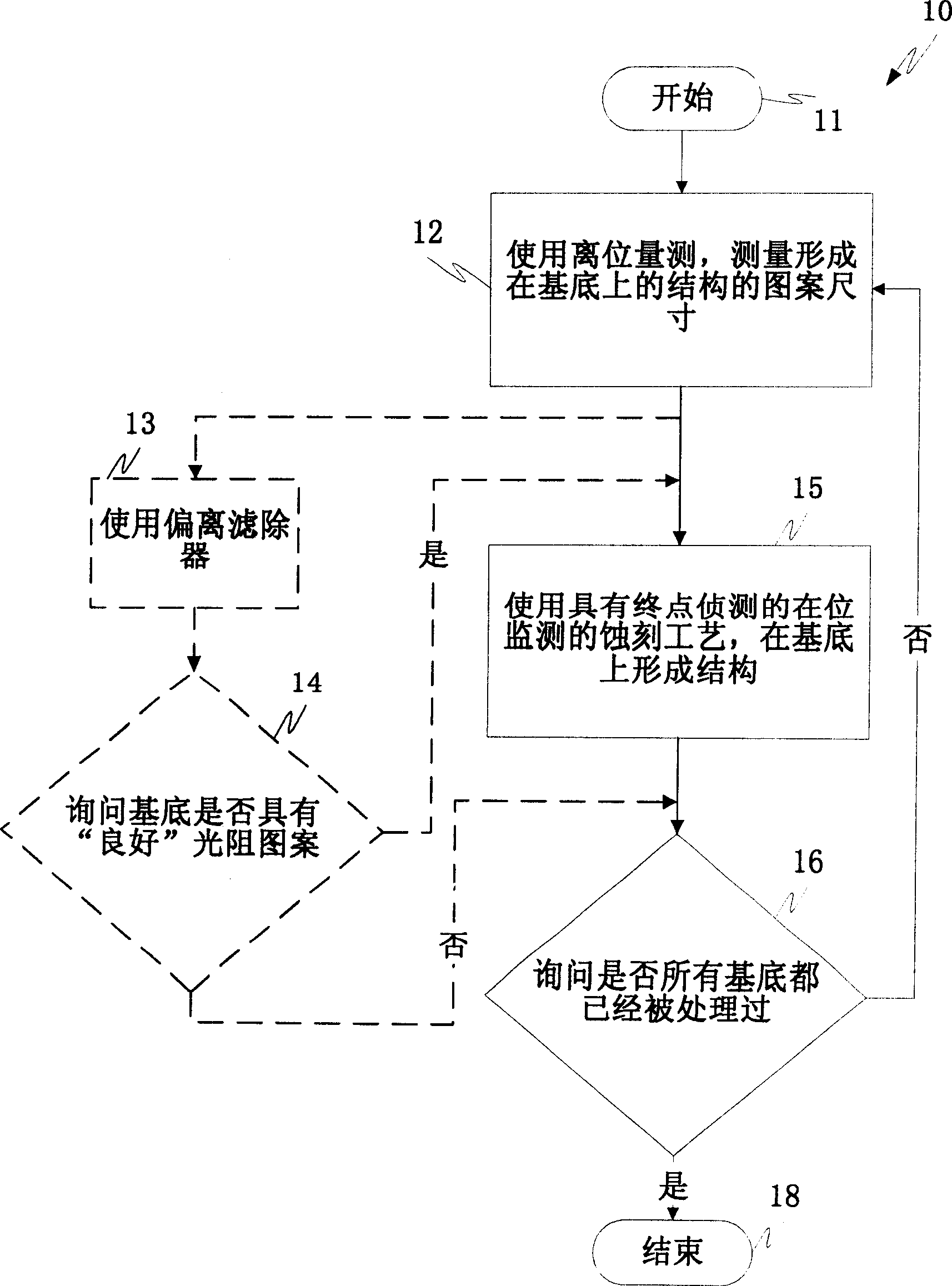

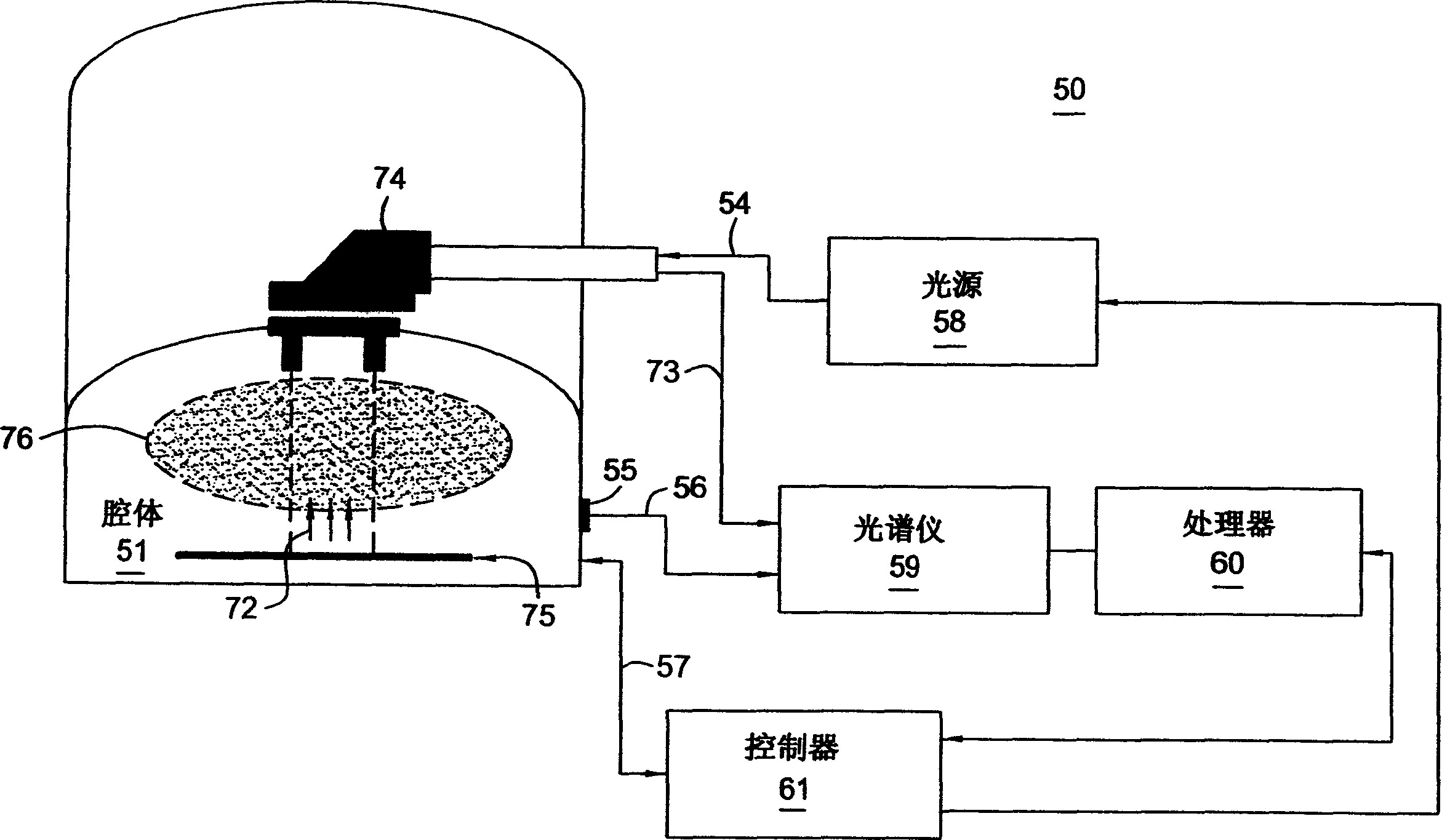

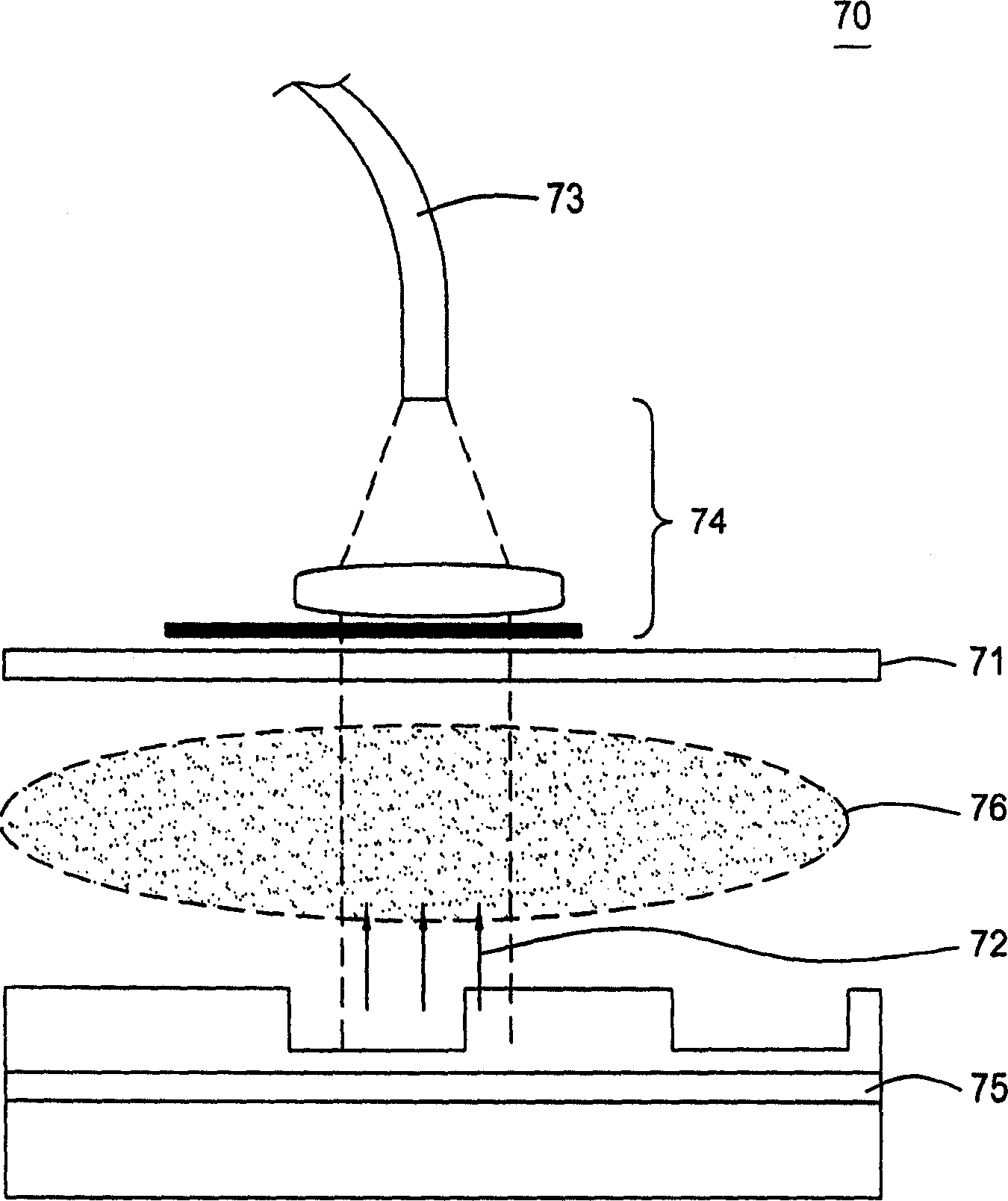

[0120] The present invention relates to a method and a system for monitoring an etching process. The etch process can be monitored using metrology information (eg, critical dimension (CD), or thickness of layers, etc.). The metrology information is obtained through ex-situ and in-situ monitoring (e.g., spectroscopic analysis, interferometry, scatterometry, and Reflectometry, etc.) provided. Off-site measurement information and on-site monitoring can be used to monitor, for example, an end point of an etching process, a feature of the etch depth profile formed on a substrate, and fault detection of an integrated circuit process, etc. . Error detection for an integrated circuit process may include, for example, monitoring the etch process to decide to terminate the process when the critical dimension (CD) of the etched feature falls outside a predetermined range.

[0121] Ex-situ measurements are performed before or after the etch process. The off-site measurement informatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com