Electrostatic eliminator for product line

A static eliminator and production line technology, which is applied in the field of static electricity devices, can solve the problems of poor static electricity elimination effect, low cost, and complexity of static electricity elimination devices, and achieves excellent static electricity elimination effects, good preventive effects, and simple production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be specifically described below in conjunction with the accompanying drawings and specific embodiments.

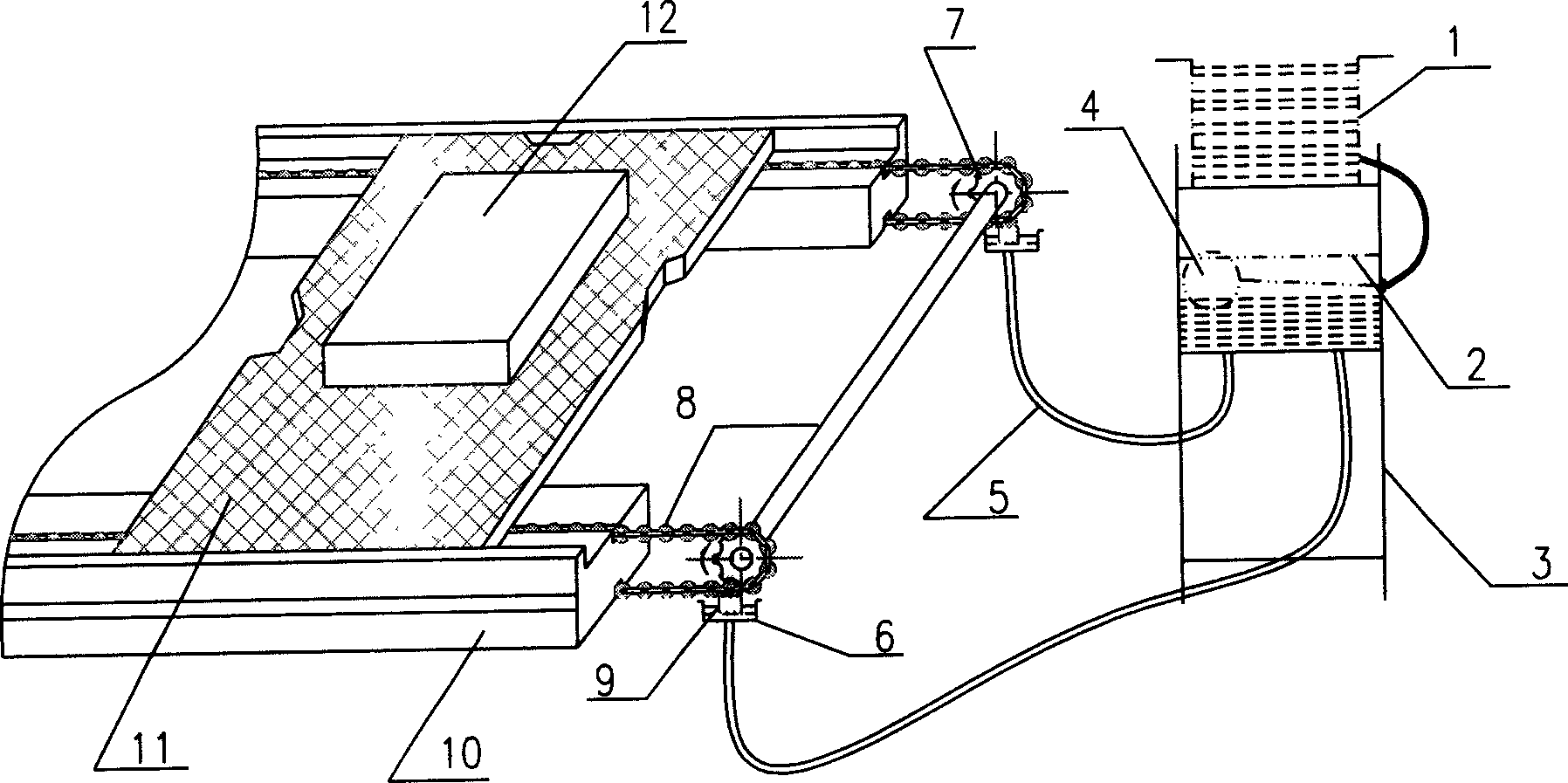

[0022] The production line static eliminator of the present embodiment is as shown in the figure, mainly has replenishing water tank 1, control water tank 2, water float and switch 4, support 3, water-absorbing sponge 9, hold water box 6, plastic hose 5 several.

[0023] Place replenishment water tank 1 and control water tank 2 each one on support 3, connect with plastic hose 5 between two water tanks, replenishment water tank 1 is positioned at the top of control water tank 2. A water float and a switch 4 that controls the water level and switches automatically are placed in the control water tank 2, so that the water level in the control water tank is always kept at a fixed water level.

[0024] The production line has a guide rail 10, a bakelite mounting plate 11, a workpiece 12, a sprocket 7 and a double-speed sprocket 8, the sprocket ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap