Device and method for manufacturing bead array, and method for detecting target substance

A manufacturing method and technology for manufacturing devices, which can be used in biological testing, measuring devices, chemical instruments and methods, etc., and can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

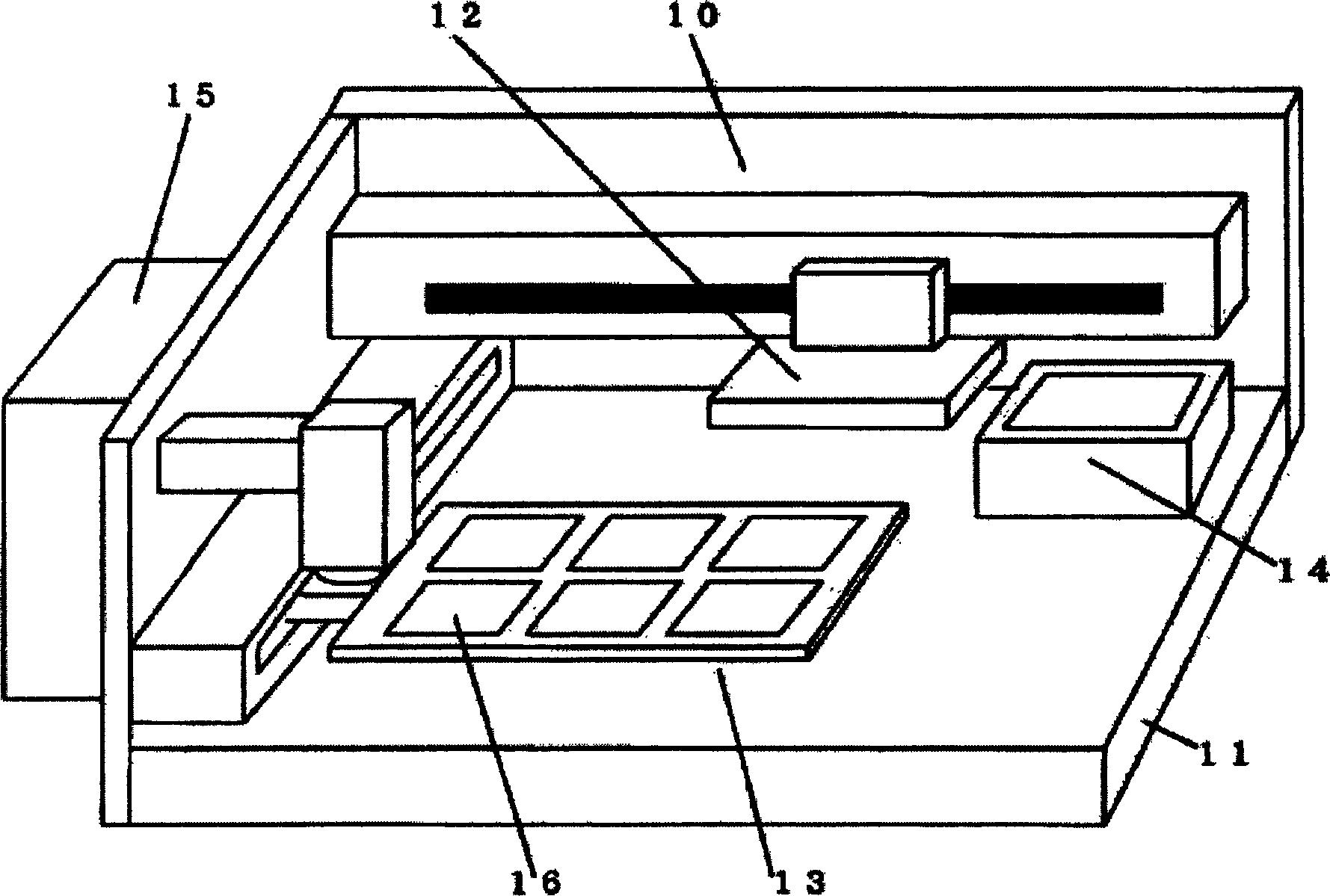

[0040] figure 1 It is a perspective view showing the outline of the microarray manufacturing apparatus used in this example. The microarray manufacturing apparatus 10 is equipped with a chuck support (sledge) 12 that can reciprocate on the X-axis on the base 11 and a table 13 that can reciprocate in the Y-axis direction perpendicular to the X-axis. A suction unit 14 for filling the ejection liquid, and a carriage and table driving unit 15 are disposed at the starting point position of the holder 12 (a storage position in an area other than the movable area of the table 13 ). The driving unit 15 moves the chuck holder 12 and the stage 13 by a numerical control method, etc., using a timing pulley mechanism or a ball screw mechanism, so as to determine the supply position of the ejection liquid to the microarray substrate 12 . A discharge head (not shown) is mounted on the chuck holder.

[0041] In this embodiment, a discharge head using an electrostatic driver is used. fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com