Manufacturing process of drawn anti-felting worsted yarn, drawn anti-felting worsted yarn and low speed drawing machine

A technology of worsted spinning and woolen yarn, which is applied in the direction of textiles and papermaking, and can solve problems such as hydraulic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Precursor preparation

[0038] First, worsted yarn used as a raw material used in the method of the present invention will be described.

[0039] The worsted wool yarn used in the present invention includes pure wool and wool blended yarn, but is not limited thereto. In particular, with the method of the present invention, high-quality fine-count worsted yarns can be produced from cheap medium-count or coarse-count worsted yarns, which has a cost advantage.

[0040] Since the spinning of worsted wool yarn in the present invention can be carried out by the spinning method of worsted wool yarn known in the art, and commercially available worsted wool yarn can be used in the present invention, the description about spinning of worsted wool yarn is omitted. detail.

[0041] It is not preferable to use a less twisted yarn as the worsted yarn stretched by the method of the present invention because slippage occurs during stretching due to insufficient bonding force and fr...

Embodiment 1

[0088] Wool fibers having a denier of 21.7 μm were spun to produce 1 / 40 Nm worsted wool yarn of 100% wool. After two-for-one twisting of the worsted wool yarn, twisting with S950 TPM and vacuum setting at 98°C.

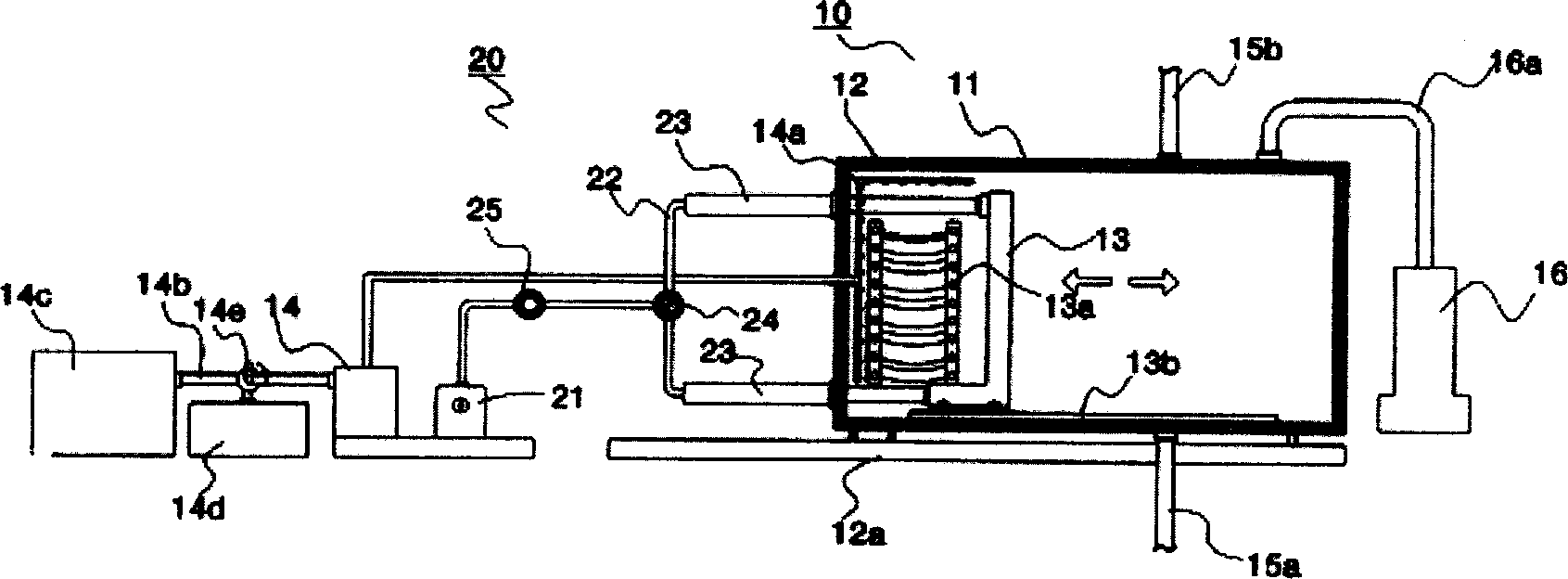

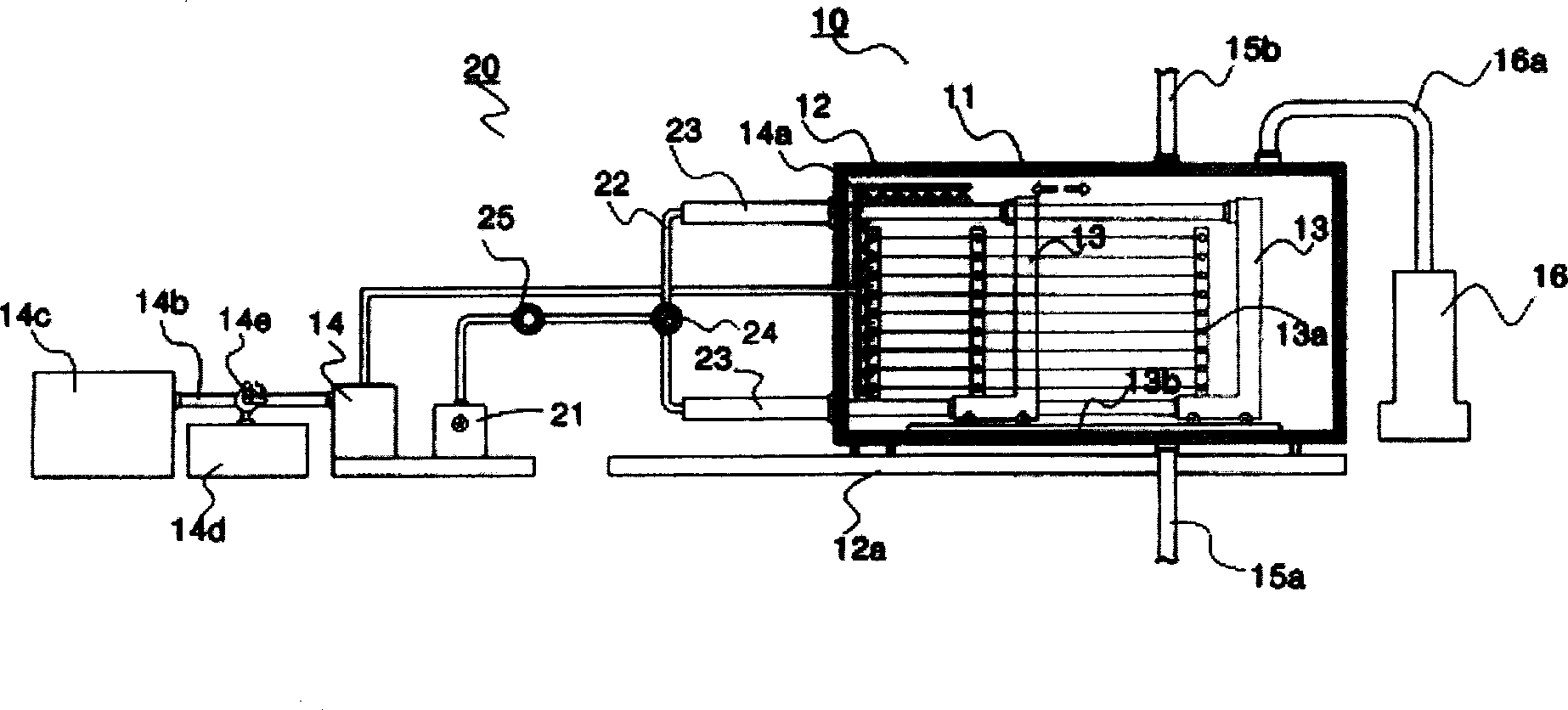

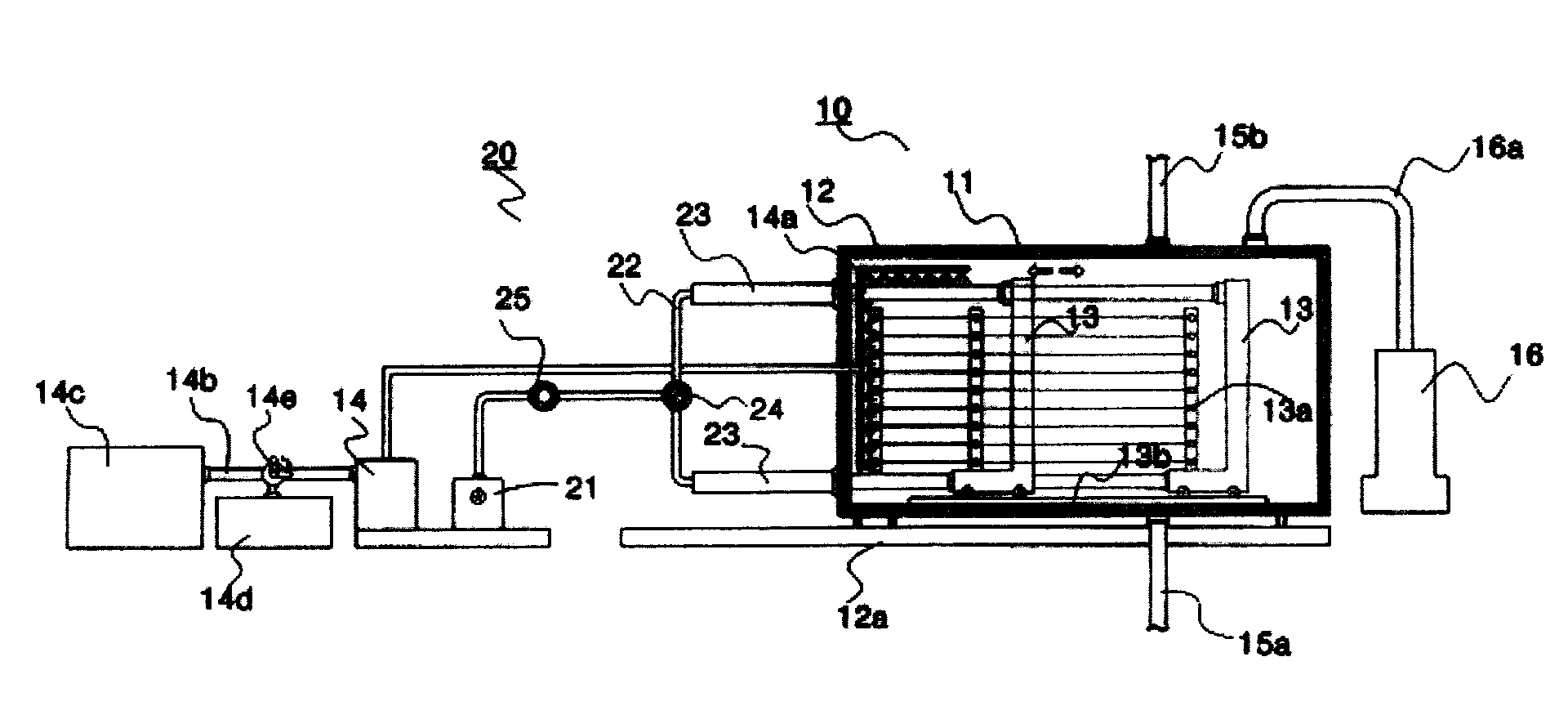

[0089] The shaped worsted wool yarn was wound into a skein form having a size of 12 cm, and then loaded on a pair of draw rolls installed horizontally inside the pressure-resistant tank. After closing the pressure tank, the rolls were rotated for 5 minutes while a sufficient 2.0 g / l aqueous solution of sodium bisulfite was sprayed on the worsted wool.

[0090] Thereafter, after the pressure-resistant tank was evacuated to 70%, steam was supplied into the pressure-resistant tank to raise the internal temperature to 110°C. This temperature was maintained for 10 minutes to evenly retain the wool. The worsted woolen yarn was stretched slowly for 30 seconds to 300 seconds to 1.7 times its original length and relaxed by 15%.

[0091] The relaxed drawn yarn was set at 98°...

Embodiment 2~3

[0094] Two wool fibers having a denier of 20.5 μm were spun to produce worsted wool yarns each of 1 / 60 Nm. After two-for-one twisting of the worsted wool yarn, it was twisted with the S120 TPM. Subsequently, low-speed drawing of the worsted woolen yarn was carried out in the same manner as in Example 1. At this time, the elongation rate of the worsted wool yarn was 135% (Example 2) and 150% (Example 3), and the relaxation was performed at 0% (Example 2) and 5% (Example 3).

[0095] Determination of physical properties of drawn worsted wool yarn. The results are summarized in Table 1 below.

[0096] physical properties

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com