Ultralow-density polyurethane midsole or insole composite material containing recoverable waste particles and preparation method thereof

An ultra-low density, polyurethane technology, applied in the field of polyurethane, can solve the problems of mechanical properties to be improved, high molding defect rate, high cost, achieve the comprehensive advantages of excellent low density and high mechanical properties, reduce product density, adhesiveness Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

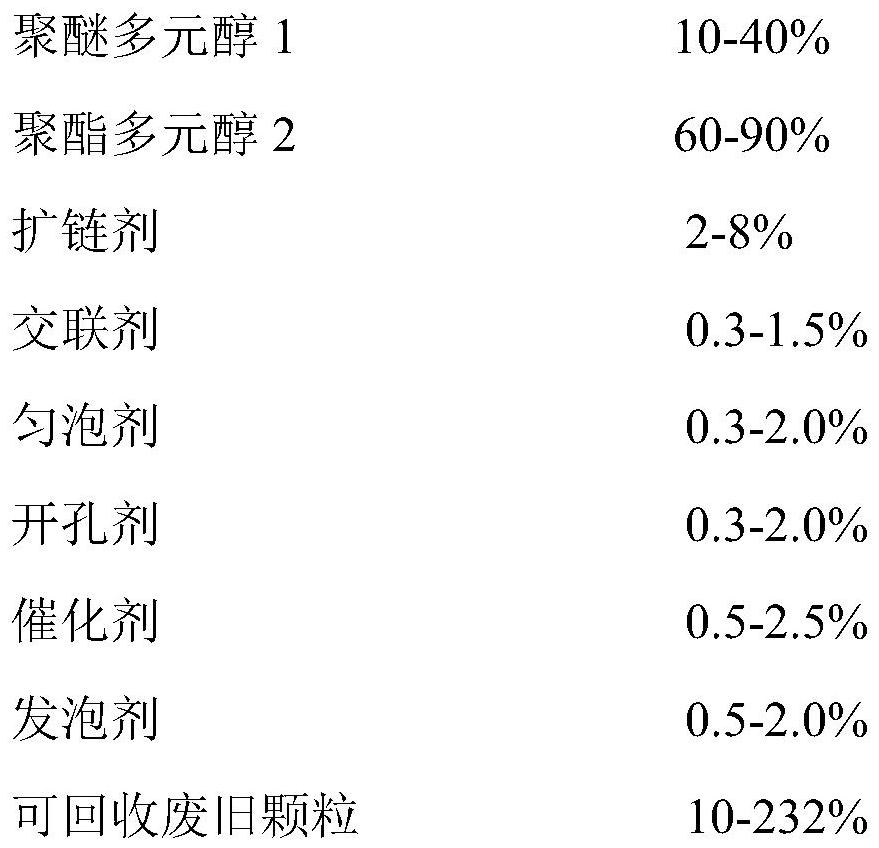

[0035] A component comprises the raw material of following mass percentage:

[0036]

[0037]

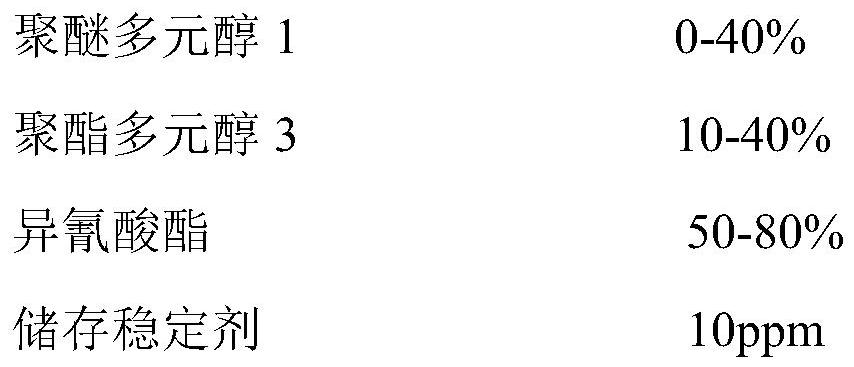

[0038] Component B includes the following raw materials in mass percentages:

[0039]

[0040] Other raw materials of component A that do not contain recyclable waste particles: Polyether polyol 1 uses ED-28 with a functionality of 2.0 and a molecular weight of 4000 (manufactured by Shandong Bluestar Dongda Chemical Co., Ltd.), and ethylene glycol , diethylene glycol, 1,4-butanediol and adipic acid through polycondensation reaction to obtain polyester polyol 2 with a number average molecular weight of 1800, the chain extender is ethylene glycol, and the crosslinking agent is diethanolamine. The foaming agent is B8905, the cell opening agent is IMR412T, the catalyst is a compound of Dabco XD104 and Dabco XD102 in a weight ratio of 1:1, and the foaming agent is water; put it into the reaction kettle in proportion at room temperature, and stir for 1 hour to get Other raw mate...

Embodiment 2

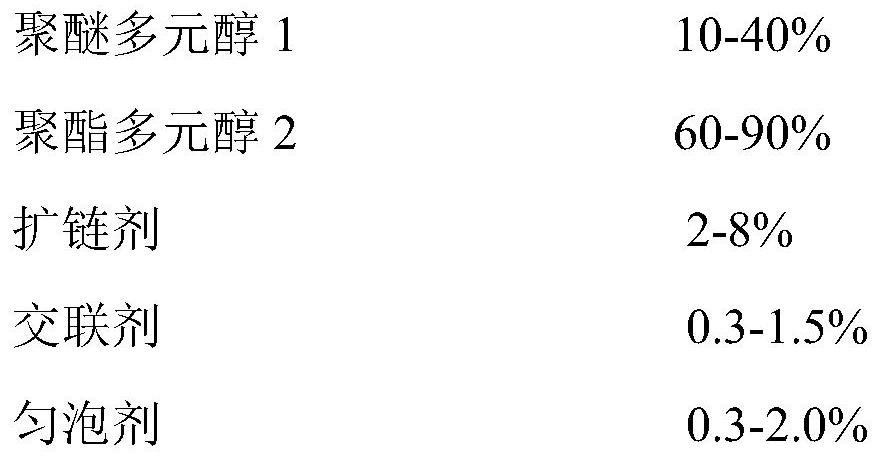

[0045] A component comprises the raw material of following mass percentage:

[0046]

[0047] Component B includes the following raw materials in mass percentages:

[0048]

[0049]Other raw materials of component A that do not contain recyclable waste particles: Polyether polyol 1 uses DL-3000D with a functionality of 2.0 and a molecular weight of 3000 (manufactured by Shandong Bluestar Dongda Chemical Co., Ltd.), and ethylene glycol 1. Diethylene glycol and adipic acid undergo polycondensation to obtain polyester polyol 2 with a number average molecular weight of 1500. The chain extender is ethylene glycol, the crosslinking agent is triethanolamine, the foam stabilizer is B8905, and the cell opener It is IMR412T, the catalyst is a compound of Dabco XD104 and Dabco XD102 according to the weight ratio of 1:2, and the foaming agent is water; it is put into the reaction kettle in proportion at room temperature, and after stirring for 2 hours, A that does not contain recycl...

Embodiment 3

[0054] A component comprises the raw material of following mass percentage:

[0055]

[0056] Component B includes the following raw materials in mass percentages:

[0057]

[0058] Other raw materials of component A that do not contain recyclable waste particles: polyether polyol 1 uses PPG6000 with a functionality of 2.0 and a molecular weight of 6000 (manufactured by Kumho Petrochemical Company of Korea), and ethylene glycol and diethylene glycol 1, 6-hexanediol and adipic acid undergo polycondensation reaction to obtain polyester polyol 2 with a number average molecular weight of 2000, the chain extender is ethylene glycol, the crosslinking agent is diethanolamine, and the foam stabilizer is B8905, The cell opener is IMR412T, the catalyst is a compound of Dabco XD104 and Dabco XD102 at a weight ratio of 2:1, and the foaming agent is water; put it into the reaction kettle in proportion at room temperature, and stir for 1 hour to obtain no recyclable waste Other raw m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com