Digit controlled machine tool real time error compensator for off centering machine tool exterior coordinate system

A numerical control machine tool and real-time compensation technology, which is applied to feeding devices, automatic control devices, metal processing machinery parts, etc., can solve the problems of high cost of foreign exchange, poor reliability, narrow application range, etc., and achieve convenient and simple compensation implementation, effective compensation, and The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

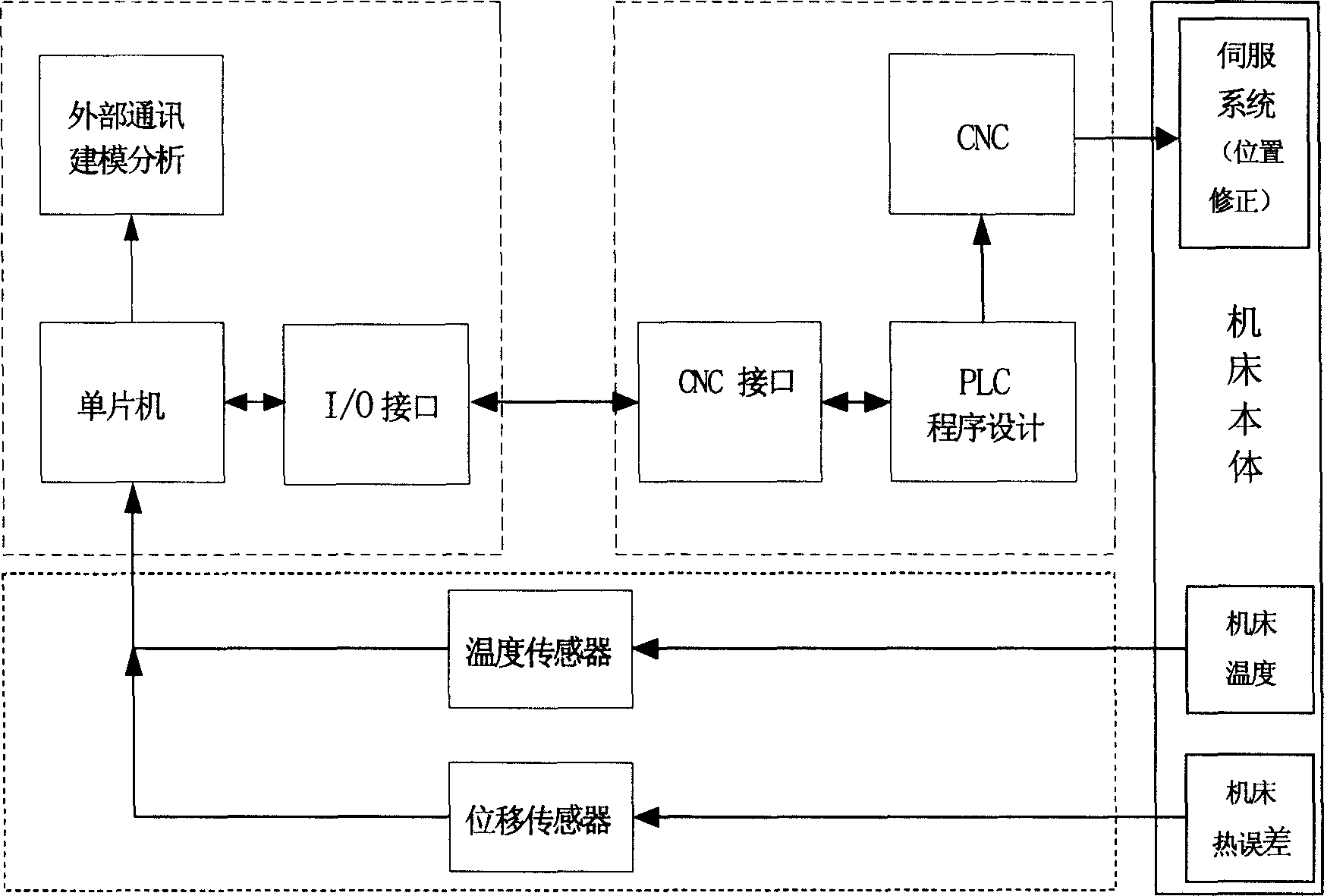

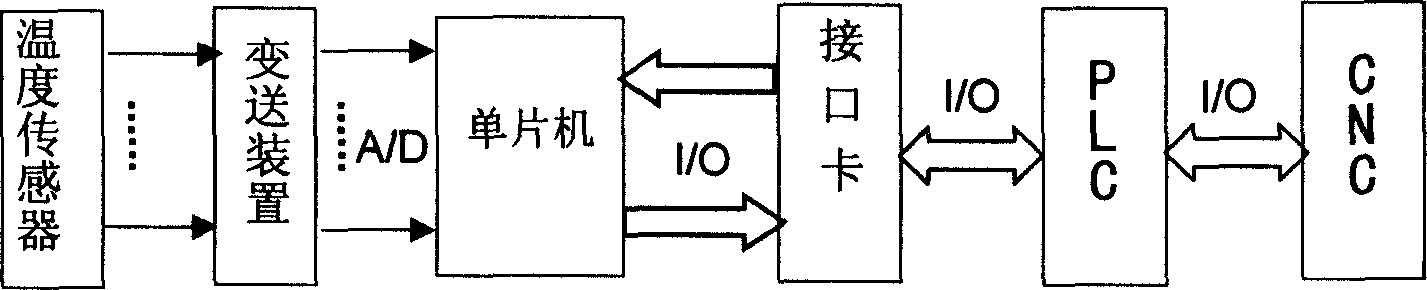

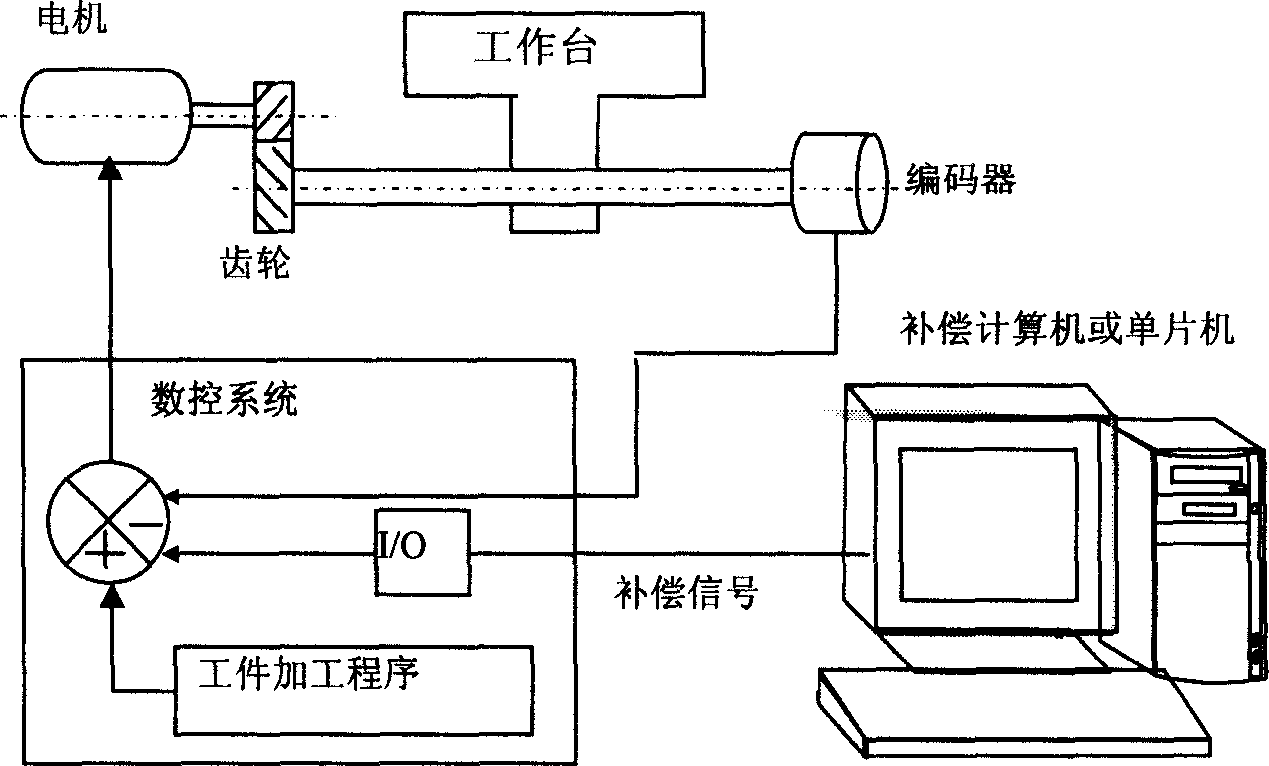

[0014] Such as figure 1 As shown, the present invention includes: calculation processing module, CNC interface and motion control module, sensor and transmission module, connected by data line between sensor and transmission module and calculation processing module, calculation processing module and CNC interface and motion control module They are connected through data lines and communication protocols. The calculation and processing module realizes the input and output, storage and calculation of signals. The CNC interface and motion control module accept the signals output from the calculation and processing module and offset the external coordinate system of the machine tool according to the compensation value. The additional movement of the machine tool is performed through the servo system, and the sensor and the transmission module realize multi-channel acquisition of the temperature and thermal error signals of the machine tool, and the signal is processed and input to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com