Control apparatus and control method for loading light oil products

A light oil product and control device technology, applied in distribution devices, special distribution devices, liquid distribution, transportation or transfer devices, etc., can solve problems such as product integration difficulties, lack of openness, poor scalability, etc., and achieve reasonable design , easy to manufacture, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

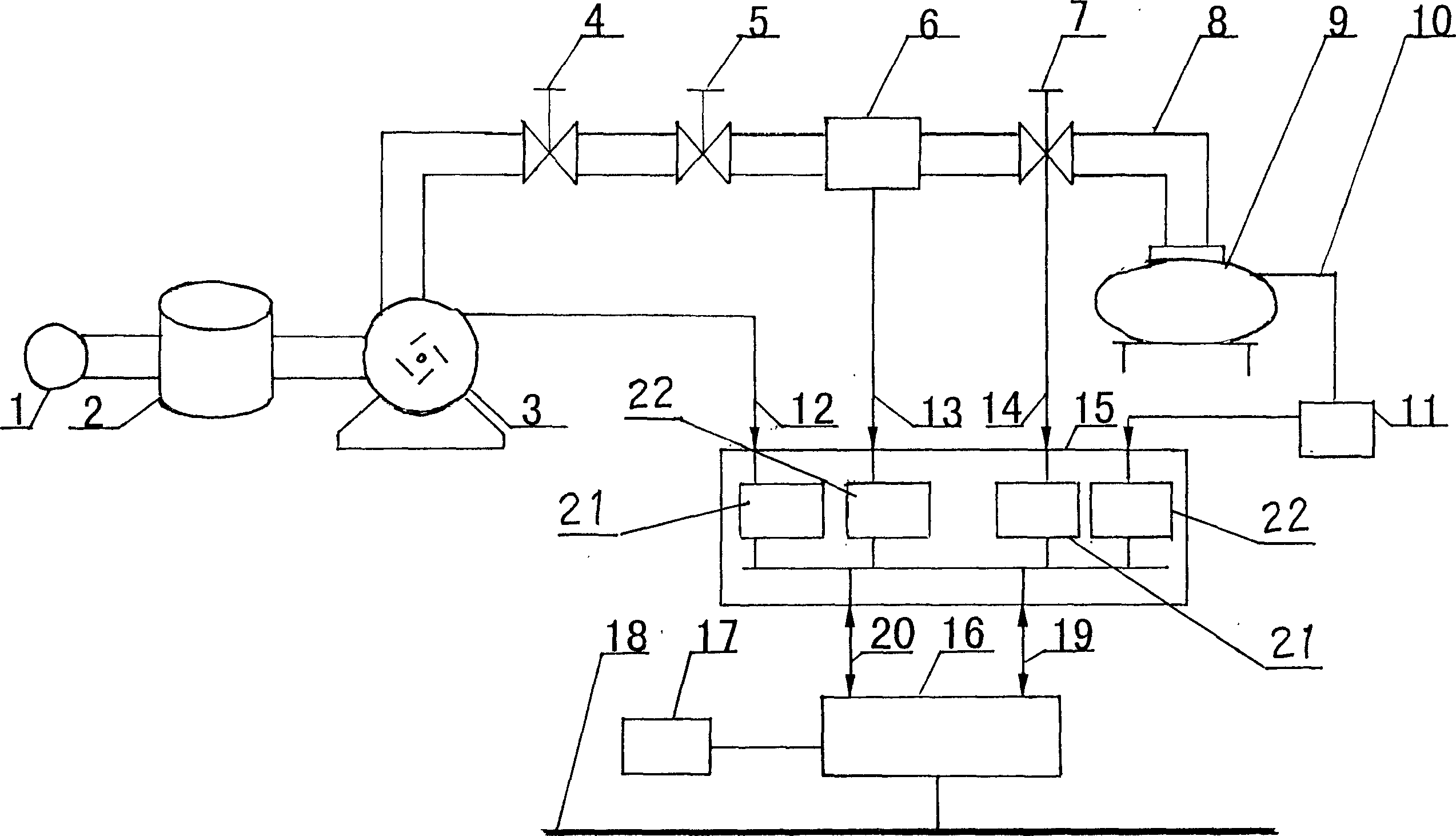

[0032] Example 1: The structure of the present invention is as figure 1 with figure 2 As shown, the software flow is as image 3 Shown. It is composed of oil inlet pipe 1, filter 2, oil pump 3, manual valve 4, one-way valve 5, flow meter 6, solenoid valve 7, automatic loading control cabinet 15 and microcomputer control device 16, oil pump 3, flow meter 6 The solenoid valve 7 is connected to the automatic loading control cabinet 15, the automatic loading control cabinet 15 is connected to the microcomputer control device 16, and the microcomputer control device 16 is connected to the Ethernet cable 18; the automatic loading control cabinet 15 is connected to the oil tanker 9 There is an anti-static device 11 between.

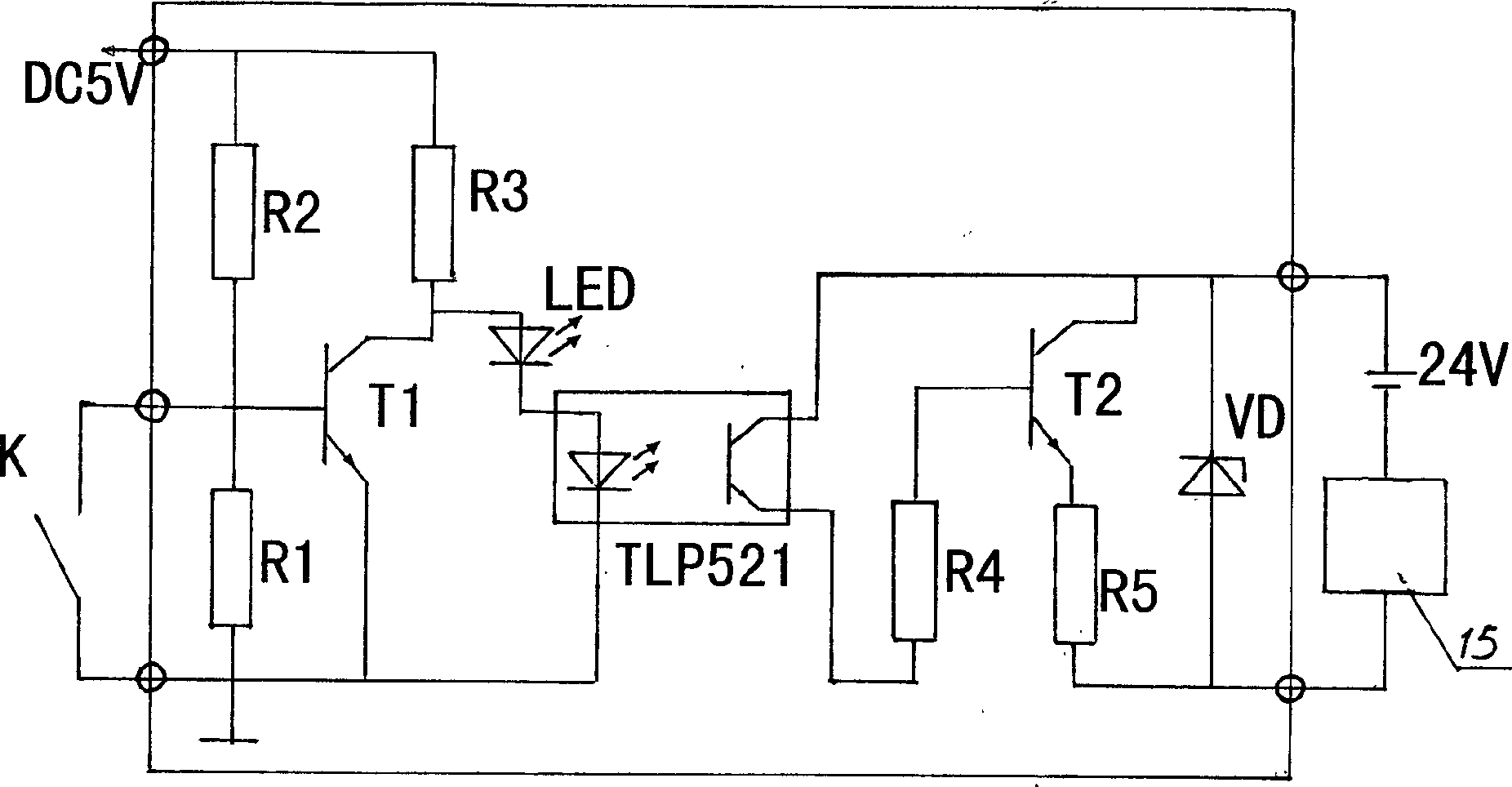

[0033] The anti-static device is composed of an explosion-proof contact suction cup switch K, two triodes T1 and T2, and a photoelectric coupler TLP521. The explosion-proof contact suction cup switch K is adsorbed on the oil tank of the tanker, and the switch K and...

Embodiment 2

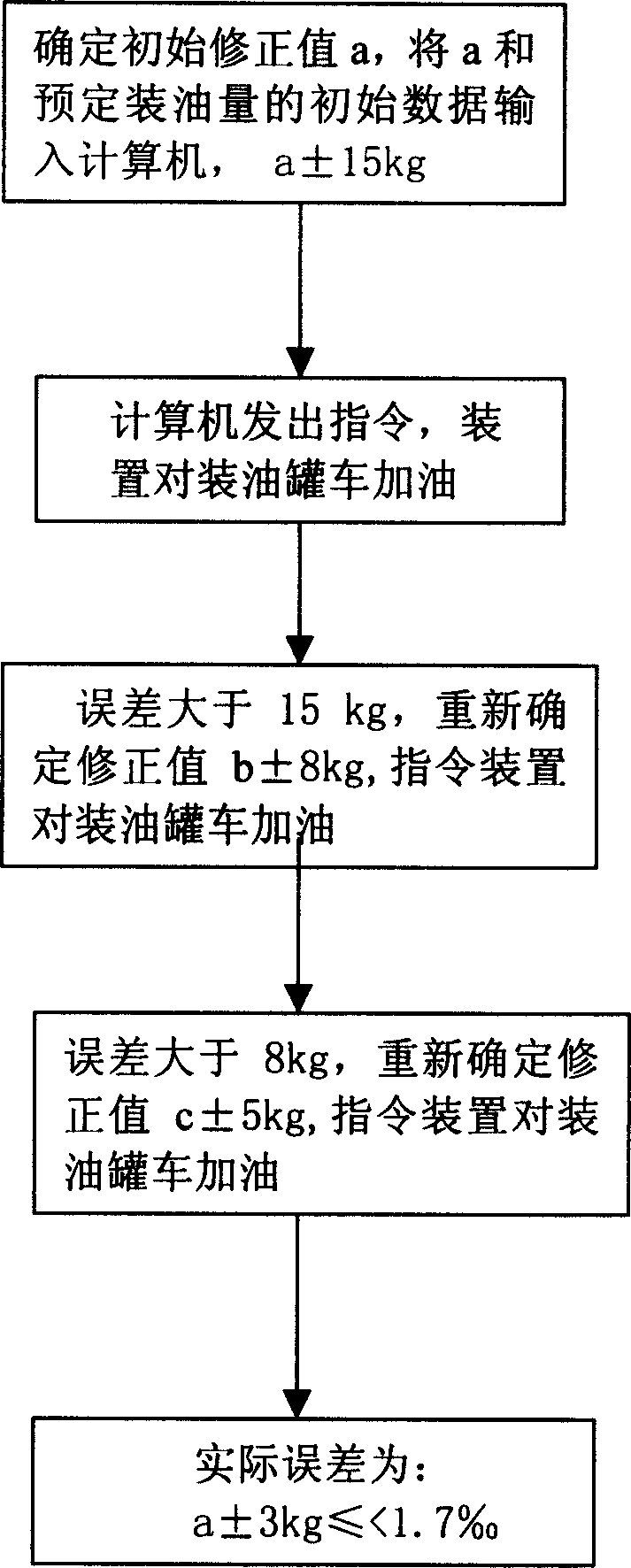

[0047] Embodiment 2: The device and method of the present invention are the same as Embodiment 1, except that the specific steps are as follows:

[0048] (1) Confirm that the initial correction value a of the oil load before starting the device is 18kg;

[0049] (2) Input the initial correction value a (18kg) of the oil filling quantity and the initial data of the predetermined oil filling quantity into the computer;

[0050] (3) The computer sends out the fueling instruction, and the oil pump and solenoid valve are activated through the automatic control cabinet to complete the fueling process of the fuel tanker;

[0051] (4) If the actual error between the actual fuel volume of the first vehicle and the predetermined fuel volume is 24kg, which is greater than a (18kg), then re-determine the correction value b as 9kg;

[0052] (5). Input the correction value b (9kg) and the initial data of the predetermined oil volume into the computer, and repeat step (3);

[0053] (6). If the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com