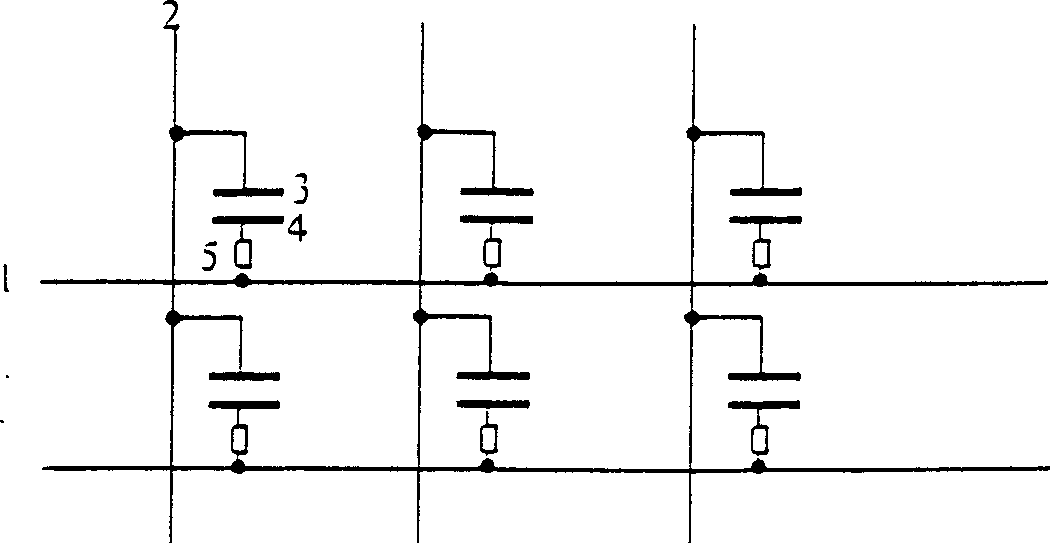

Cathode component with resistor field emission electron

A cathode component, field emission technology, applied in the direction of discharge tube/lamp parts, cathode ray tube/electron beam tube, electrical components, etc., can solve the problem of unstable field emission process, affecting emission uniformity and stability, Issues such as large fluctuations in launch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

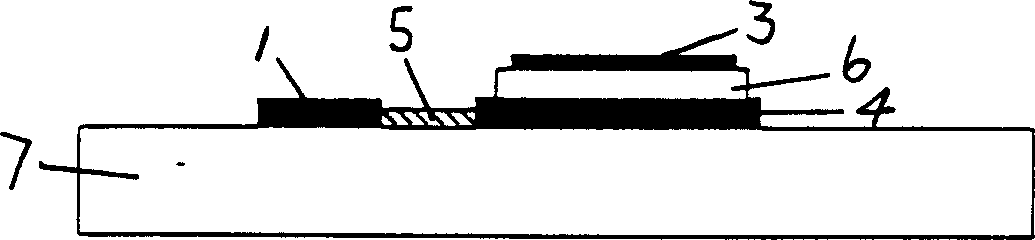

[0012] In the cathode part, the upper and lower electrodes are gold film and aluminum film respectively, the electron transport layer is aluminum oxide, the thickness is 10 nanometers, 10 nanometers and 100 nanometers respectively, and the feedback resistor is thin film amorphous silicon. The area of the transmitting unit is 0.1 square millimeters, the feedback resistance is 30 kΩ, the transmission current is 0.1 mA, the voltage drop across the resistor is 3 volts, and the driving voltage is 11 volts. Under the above conditions, the difference in emission between the units is less than 2%, which meets the basic requirements of the display device.

[0013] In the cathode part, the upper and lower electrodes are gold film and aluminum film respectively, the electron transport layer is aluminum oxide, the thickness is 10 nanometers, 10 nanometers and 100 nanometers respectively, and the feedback resistor is thin film zirconium nitride. The area of the transmitting unit is 0.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com