Welding machine fault detecting and protecting system, and its method

A fault detection and protection system technology, applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor system consistency and large performance impact, so as to protect welding parameters, reliable and effective detection, and avoid serious accidents. loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

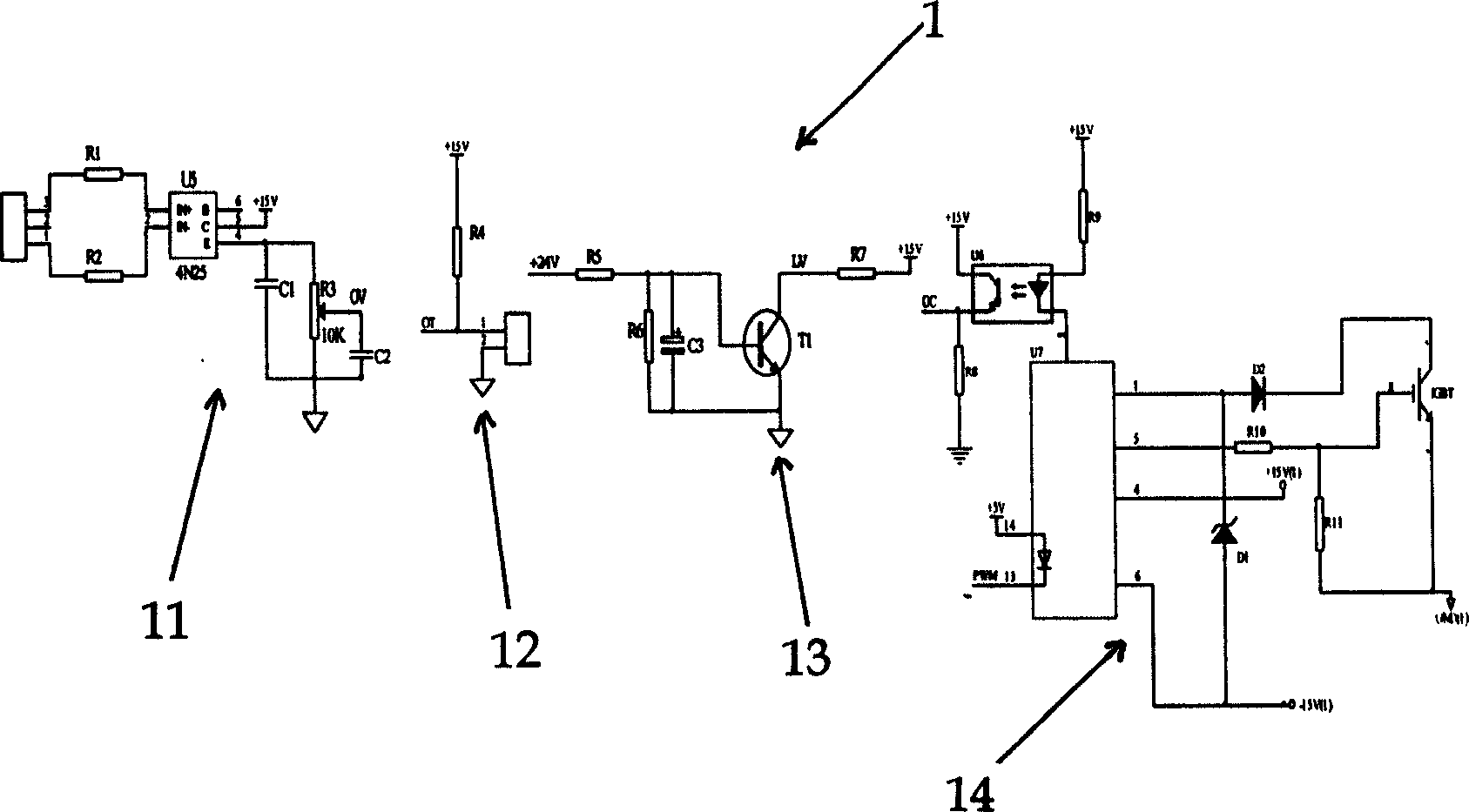

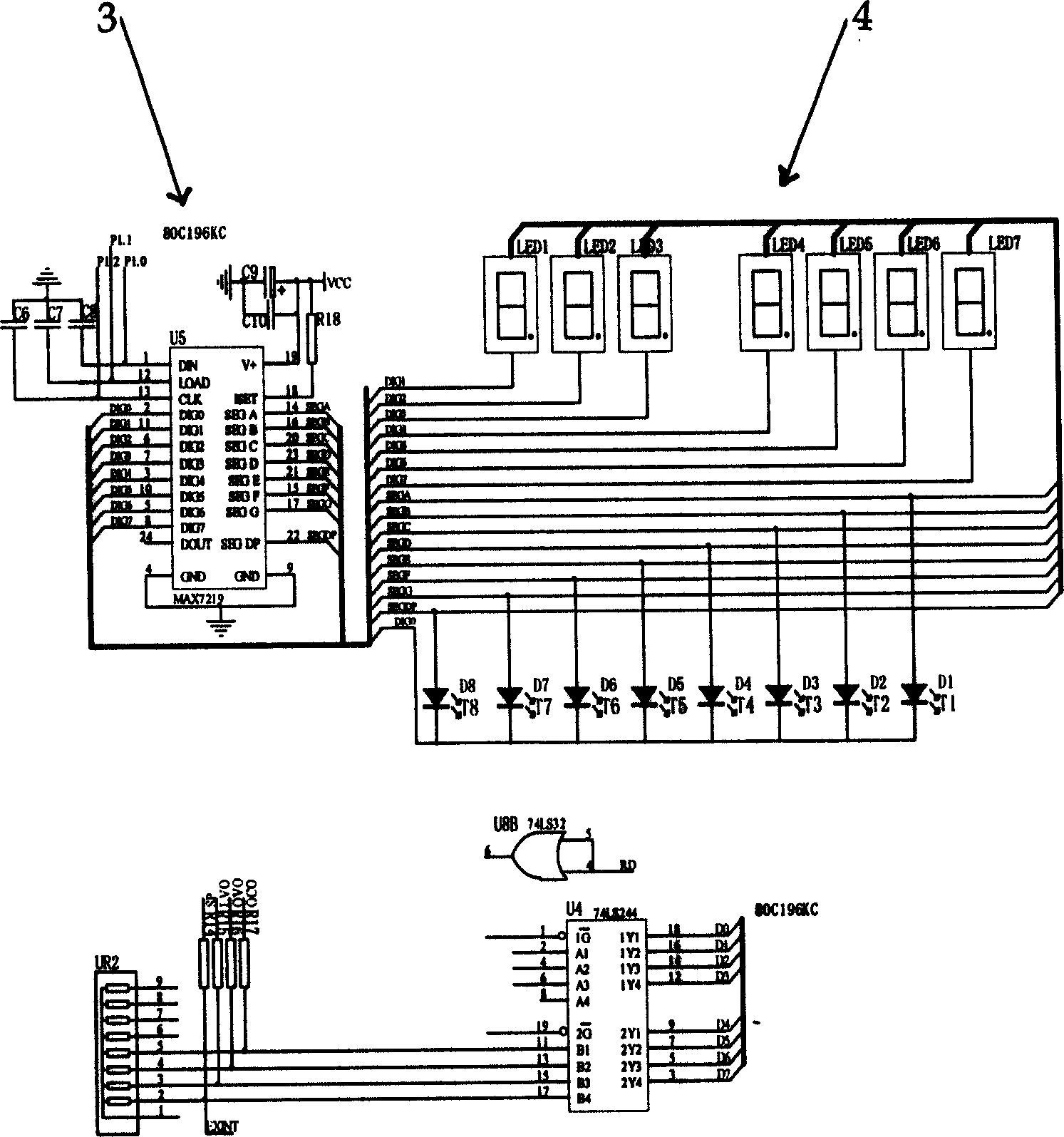

[0015] The welding machine fault detection and protection system of the present invention includes: a fault signal acquisition circuit 1 , a signal latch circuit 2 , a signal processing circuit 3 , and a display circuit 4 connected in sequence.

[0016] Such as figure 1 As shown: the fault signal acquisition circuit 1 of the present invention includes: an overvoltage signal acquisition circuit 11 , an overheat signal acquisition circuit 12 , an undervoltage signal acquisition circuit 13 , and an overcurrent signal acquisition circuit 14 . Since the above-mentioned sampling circuits are in the prior art, details will not be repeated here.

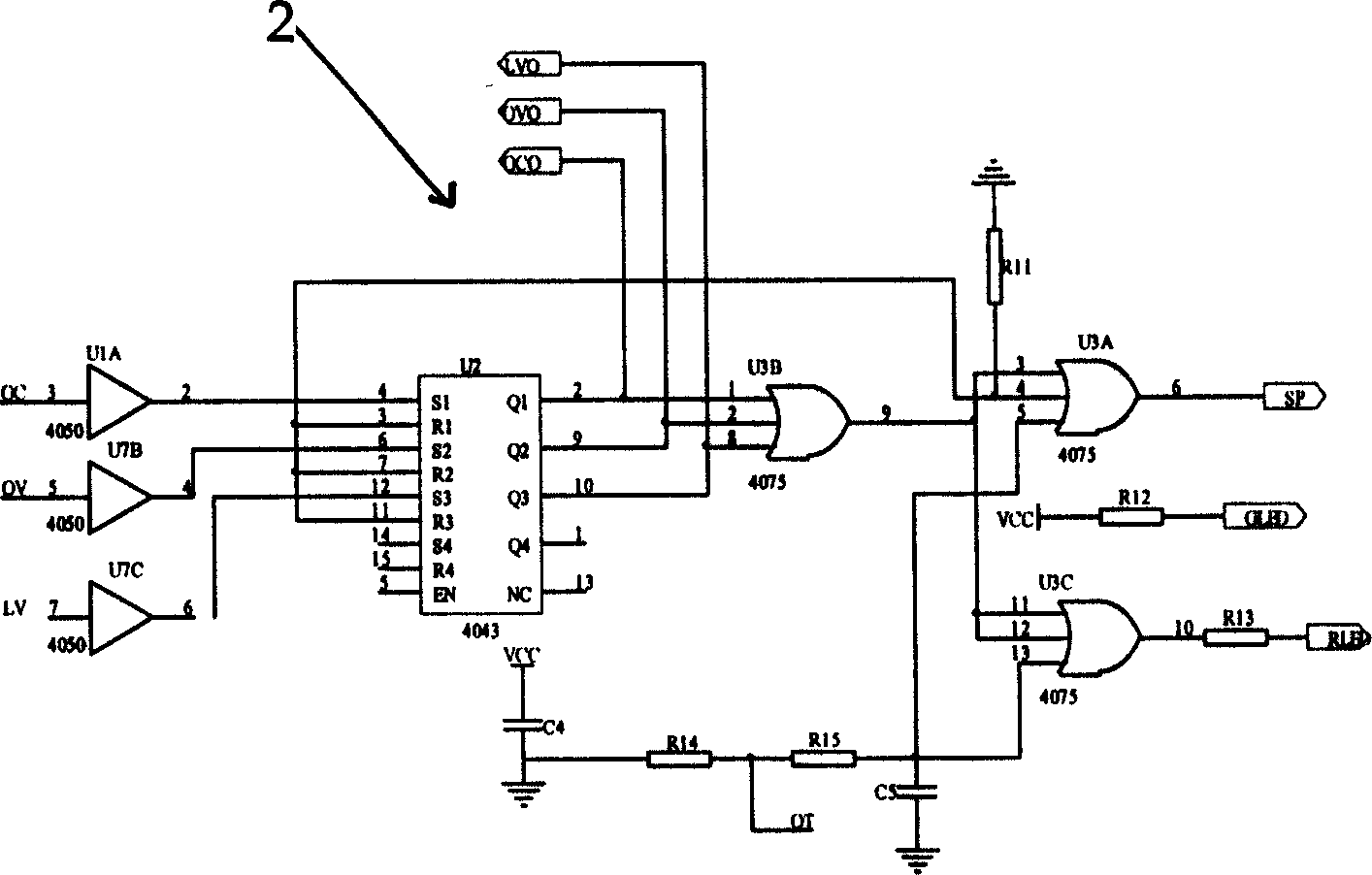

[0017] Such as figure 2 Shown: signal latch circuit 2 of the present invention receives the overcurrent, overvoltage, undervoltage signal from fault signal acquisition circuit 1, and it comprises:

[0018] Six in-phase buffer converters 4050, the over-current, over-voltage, and under-voltage signals are input to pins 3, 5, and 7 of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com