Flat type fluorescent lamp

A fluorescent lamp and flat-panel technology, applied in the direction of fluorescent lamps, light sources, discharge lamps, etc., can solve problems such as brightness differences and weakened luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

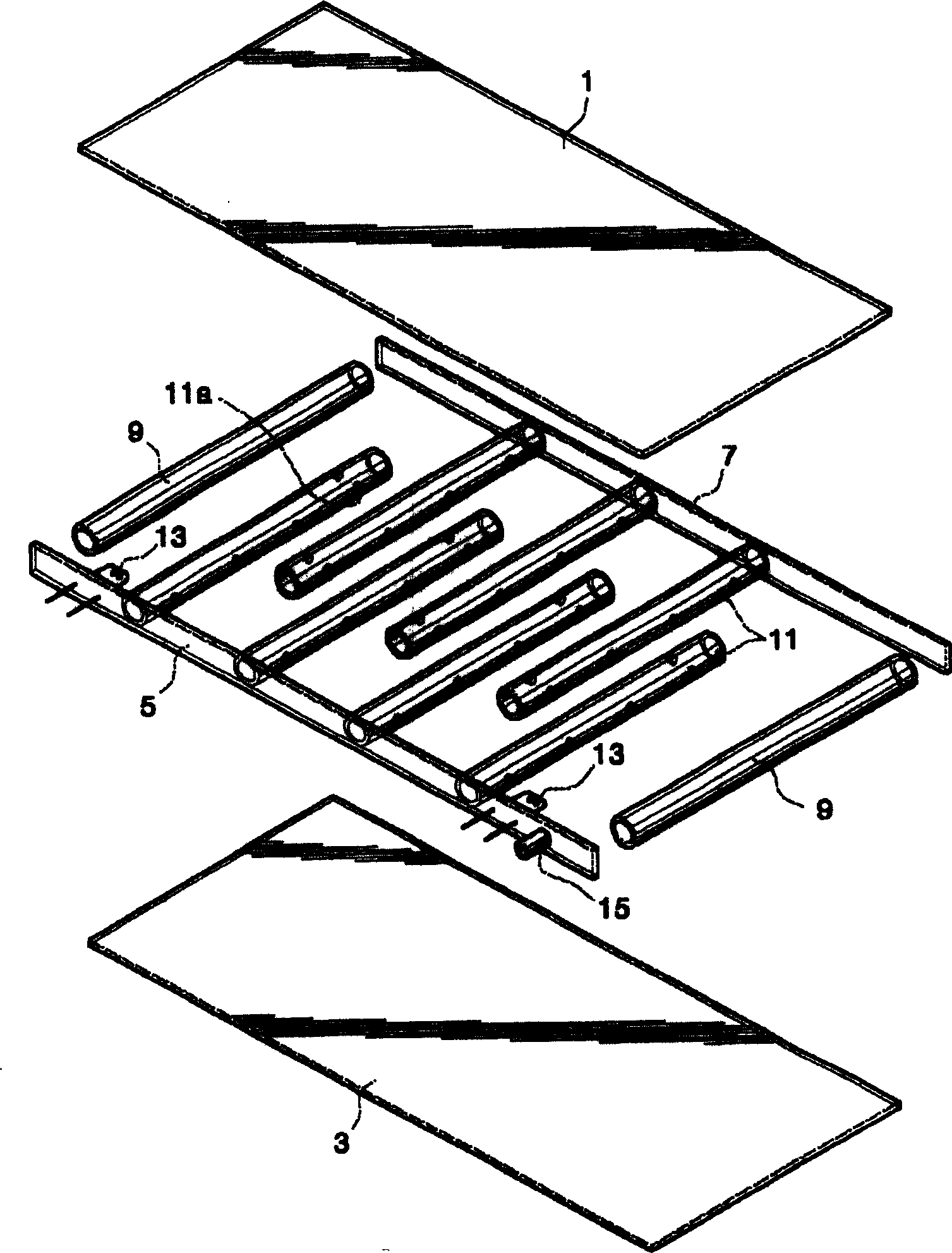

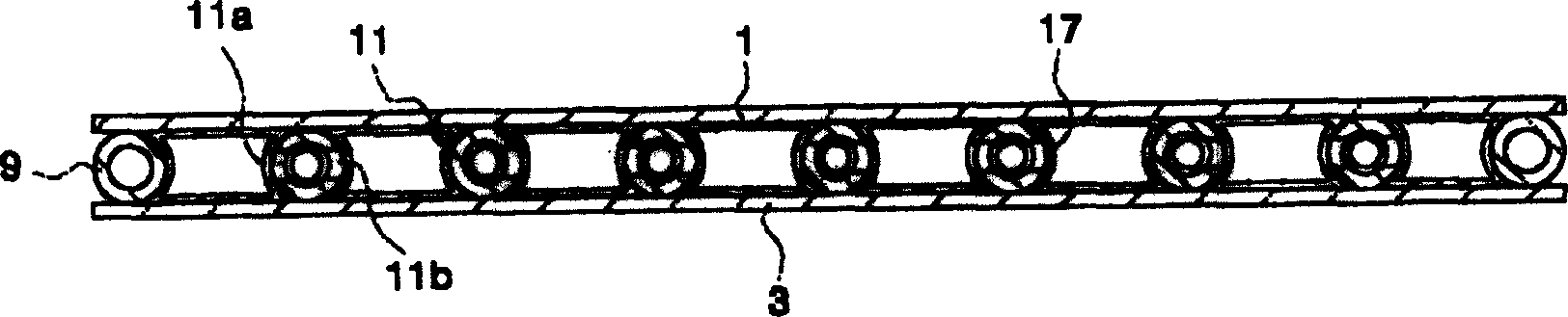

[0039] figure 1 and 2 A flat-type fluorescent lamp according to a first embodiment of the present invention is shown. As shown in the figure, the flat fluorescent lamp of the present invention is defined by a rectangular parallelepiped outer lamp body and a light emitting device for realizing a surface light source such as a backlight of a flat panel display.

[0040] The outer lamp body includes a front panel 1 and a rear panel 3 , and longitudinal and transverse seals 5 , 7 and 9 for sealing the space defined between the front panel 1 and the rear panel 3 . Here, the back plate 3 and the seals 5, 7 and 9 are made of a transparent or translucent material. Also, a reflective layer is formed on the rear plate 3 .

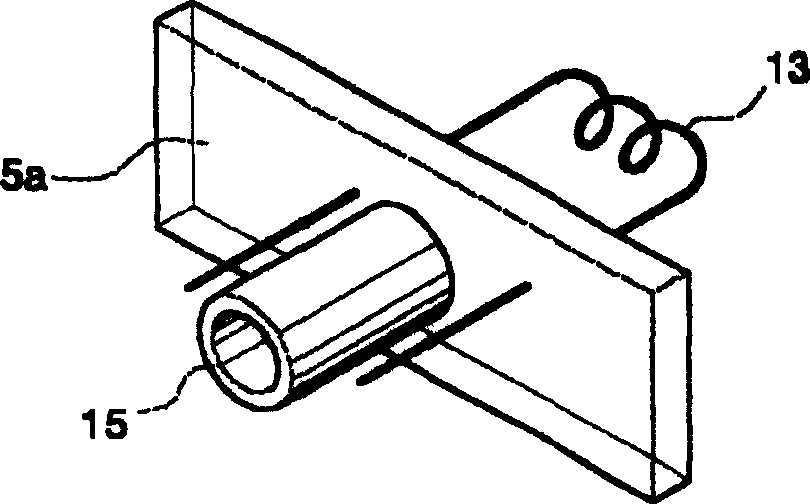

[0041] In addition, the transverse seal 9 may be formed by a tubular spacer. The length of each tubular spacer 9 is the same as the width of the outer lamp body. The longitudinal seals 5 and 7 are formed by side panels.

[0042] As a characteristic of the inven...

Embodiment 2

[0062] Figure 6 and 7 A flat-type fluorescent lamp according to a second embodiment of the present invention is shown.

[0063] As shown in the figure, the flat fluorescent lamp of the invention described in this embodiment includes the outer lamp body as in the first embodiment.

[0064] As a feature of this embodiment, a plurality of tubular spacers 111 are provided between the front panel 1 and the rear panel 3 .

[0065] Each tubular spacer 111 is designed to be shorter than the width of the outer lamp body. That is, the length of the tubular spacer 111 is 1 / 10 to 1 / 2 of the width of the outer lamp body. The tubular spacers 111 can be arranged randomly or aligned in a row. Like the first embodiment, the section of the tubular spacer 111 can be designed in various shapes, such as circular, elliptical or polygonal.

[0066] The above structure and arrangement of the tubular spacer 111 according to the present invention can make it easier to deposit the phosphor layer 1...

Embodiment 3

[0070] The third embodiment is the same as the first and second embodiments except that the phosphor layer 17 is further optimized to improve luminous efficiency and luminous brightness.

[0071] That is, in the third embodiment, the thickness "d" of the phosphor layer 17 deposited on the inner surface of the outer lamp is limited to satisfy the following range:

[0072] d=4log e W~d=4log e W+16

[0073] Among them, W represents the electric power of the lamp.

[0074] Utilize the test result that above-mentioned condition obtains as table 1 and Figure 9 shown. In this experiment, a three-wavelength phosphor was used as the fluorescent material, and for the colors of red R, green G and blue B of the fluorescent material, Y 2 o 3 :Eu, LaPO 4 : Ce, Tb and (Sr, Ca, Ba) 10 (PO 4 ) 6 C 12 :Eu. In addition, the phosphor has an average particle size in the range of 2-10 μm, and is distributed in an area of 80±10% of the entire surface area.

[0075] Alternatively, pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com