Module varying transmission mechanism

A technology of transmission mechanism and gear modulus, which is applied to transmission devices, gear transmission devices, wheel transmission devices, etc., and can solve problems such as pitting of transmission gears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

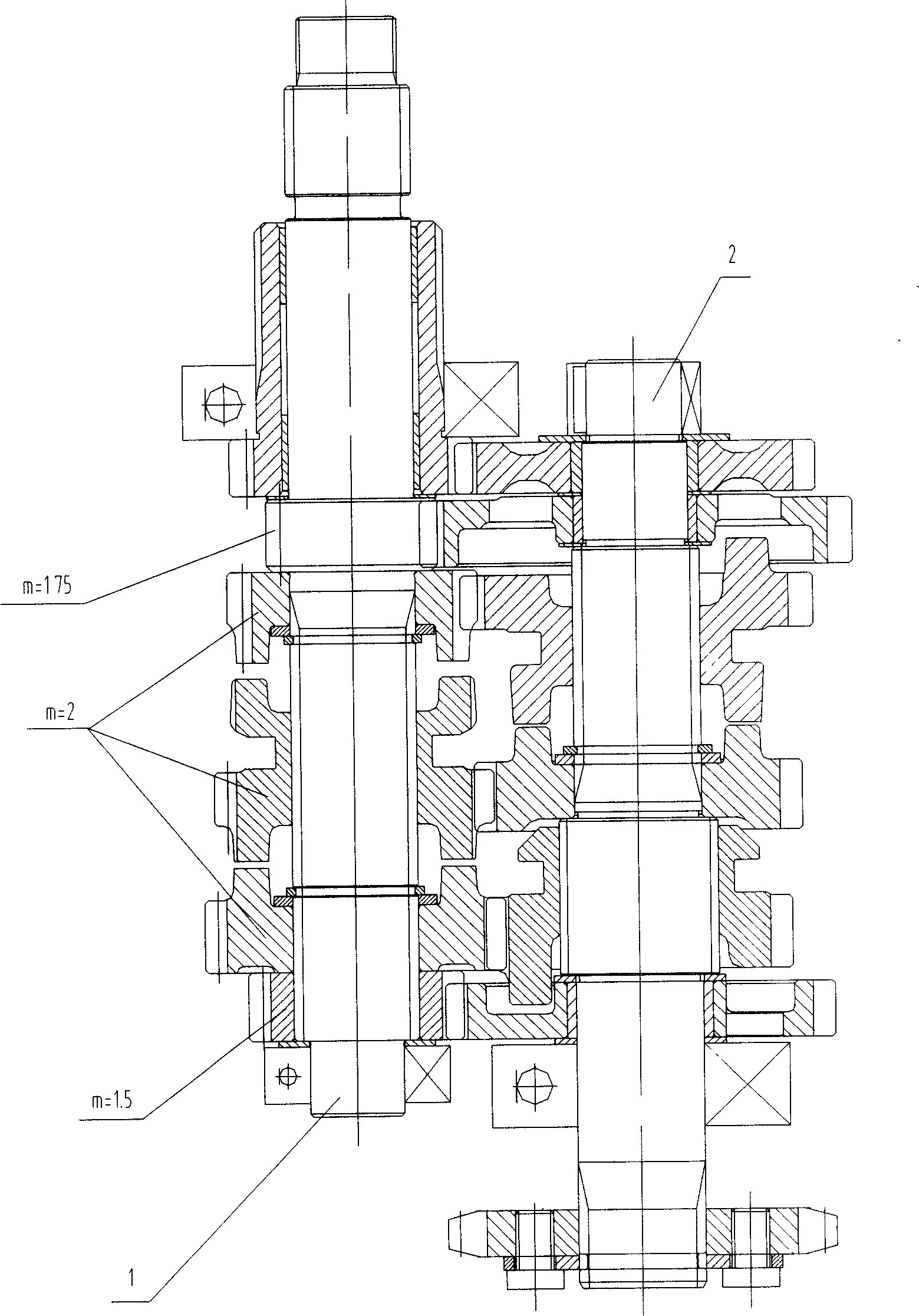

[0006] The specific structure of the present invention will be further described below in conjunction with the accompanying drawings.

[0007] see figure 1 , a variable mode transmission mechanism of the present invention, including a main shaft assembly 1 and a countershaft assembly 2, the key of which is to select different gear modules for gears of different gears to meet the requirements of different working conditions. In this embodiment: the first gear m=1.75, the second, third and fourth gears m=2, and the fifth gear m=1.5. The gear modulus is large, and the second, third, and fourth gears correspond to greater loads when the motorcycle is climbing, so the selected gear modulus is also large. The fifth gear corresponds to the flat road with the smallest load when driving at high speed, so the selected gears The modulus is the smallest. Since different gears use different modulus, each gear corresponds to the change of working conditions under normal driving, which sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com