Riser reactor

A reactor and riser technology, which is applied in the field of hydrocarbon feedstock catalytic cracking riser reactors, can solve the problems that cannot meet the cooling requirements of regenerated catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

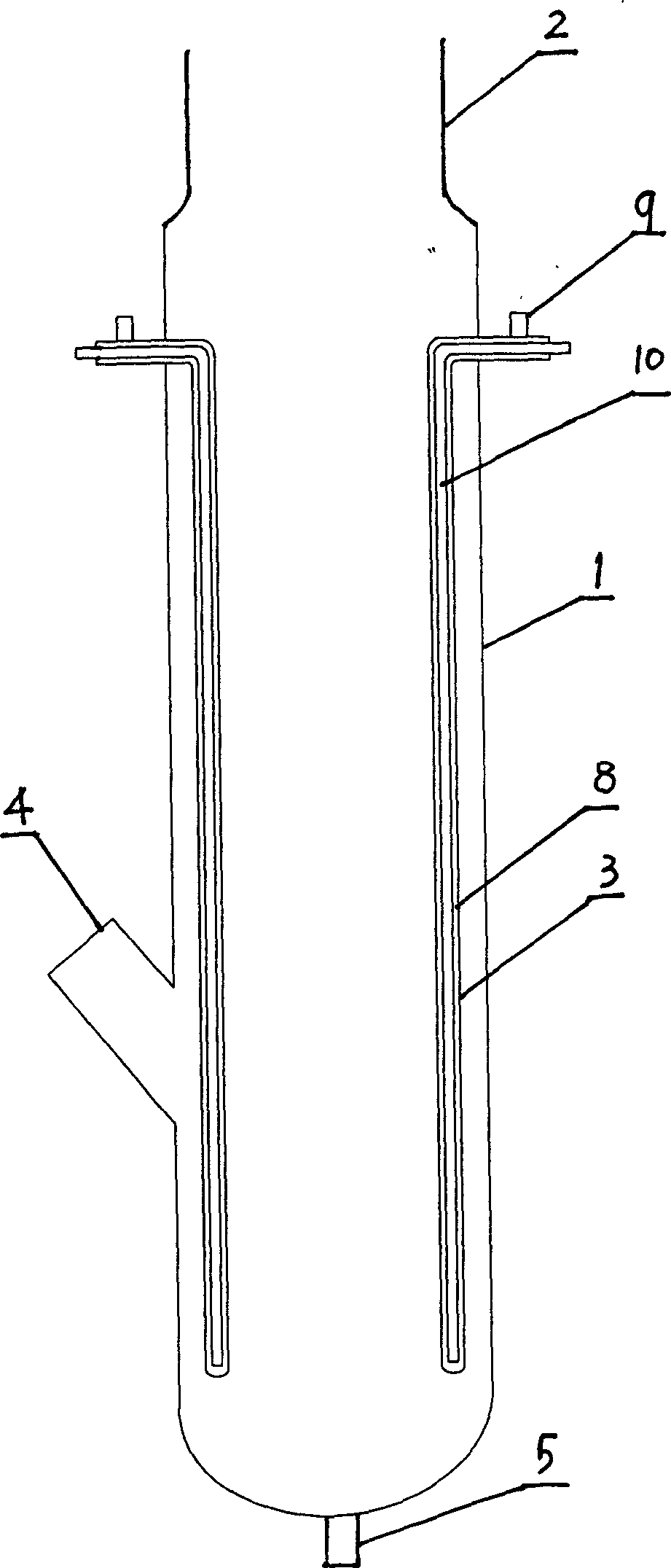

[0013] Embodiment 1. A riser reactor, comprising a reaction section 2, a catalyst heat exchange device 3 is provided in the housing of the pre-lift section 1 below the reaction section 2, a catalyst inlet pipe 4 is provided at the lower part of the side wall of the housing, and a catalyst inlet pipe 4 is provided at the lower end of the housing. There is a lifting medium to enter the pipe 5. The inner diameter of the shell of the pre-lifting section 1 is 1.1 times the inner diameter of the adjacent reaction section 2 . The heat exchange device 3 is a sleeve pipe arranged vertically along the inner side of the shell with uniform intervals, and the upper end of the sleeve pipe passes through the shell; The tube is connected, and the upper end passes through the upper end seal of the outer tube. During use, the low-temperature heat exchange medium enters from the inner tube 10 of the casing, and flows out from the outlet 9 of the outer tube 8 of the casing after absorbing heat. ...

Embodiment 2

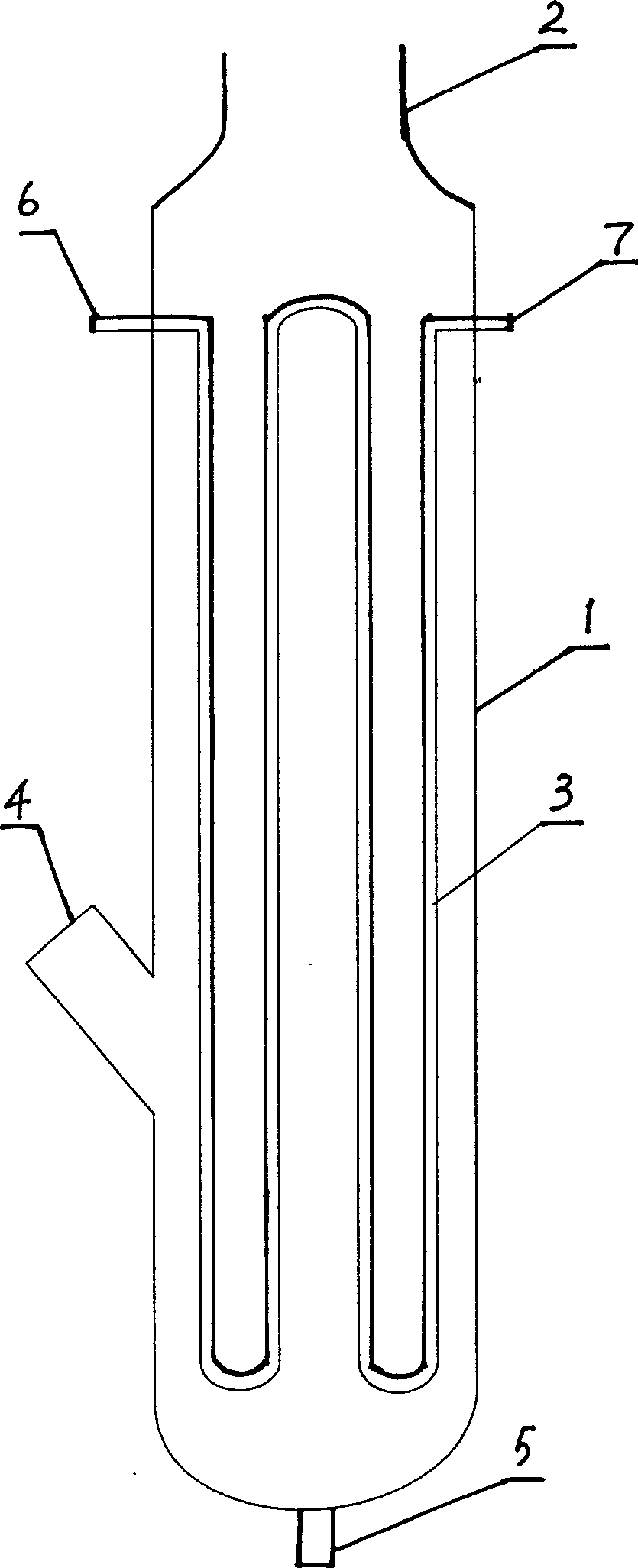

[0014] Embodiment 2. In this embodiment, the inner diameter of the casing of the pre-lifting section 1 is 1.5 times the inner diameter of the adjacent reaction section 2 . The heat exchange device 3 is a U-shaped coil vertically arranged along the inner wall of the shell, and the inlet 6 and the outlet 7 of the coil are located on the side wall of the shell of the pre-lift section 1 . During use, the low-temperature heat exchange medium enters from the inlet 6 of the coil, and flows out from the outlet 7 of the coil after absorbing heat. Others are the same as embodiment 1

[0015] In the above two embodiments, the temperature of the regenerant can be regulated by controlling the temperature and flow rate of the low-temperature heat exchange medium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com