Method for prestress binding steel reinforced concrete structure

A concrete structure and prestressing technology, which is applied in building construction, building maintenance, construction, etc., can solve the problems that the improvement effect of bearing capacity and stiffness is not obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

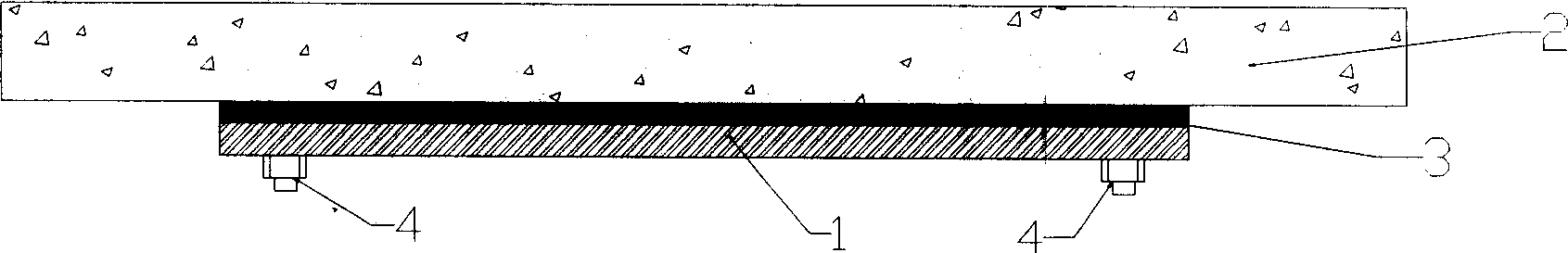

[0024] 1 The method of pasting the steel plate with initial tension to strengthen the concrete structure adopts the following process:

[0025] ①. According to the original design data of the reinforced concrete structure, as well as the inspection and evaluation of the structure, design the reinforcement parameters.

[0026] ②. Surface treatment is carried out on the reinforced structure and the bonding surface of the steel plate, mainly grinding and cleaning.

[0027] ③. Drill high-strength bolt holes at the corresponding positions of the structure to be reinforced and the steel plate (the position of the bolt hole on the steel plate should consider the elongation of the tensioned steel plate).

[0028] ④. Install the steel plate on a special stretching frame that can be used repeatedly, and stretch it to control the stress.

[0029] ⑤. Use a spatula to apply structural adhesive on the treated concrete surface and steel plate at the same time.

[0030] ⑥. Use fasteners to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com