Method for preparing X-ray austenite measuring and caliberating sample

An austenite and X-ray technology, used in the field of material analysis and testing, can solve the problems of inconvenient quantitative analysis and measurement work, and cannot ensure the reliability of measurement results, and achieve long-term stability of austenite content, beautiful surface, and easy to carry. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Provide following embodiment in conjunction with content of the present invention:

[0022] (1) Powder particle size screening

[0023] Select austenite powder and ferrite powder, use a sieve with an aperture of 5 μm to limit the maximum size of the powder, and use a sieve with an aperture of 2 μm to limit the minimum size of the powder, so that the obtained particle size distribution is controlled within the range of 2 μm to 5 μm.

[0024] (2) mixed powder

[0025] Austenite volume fraction

10%

20%

30%

40%

50%

Implementation conditions

Put it into absolute alcohol and mix powder mechanically

Implementation results

Mix the two powders evenly

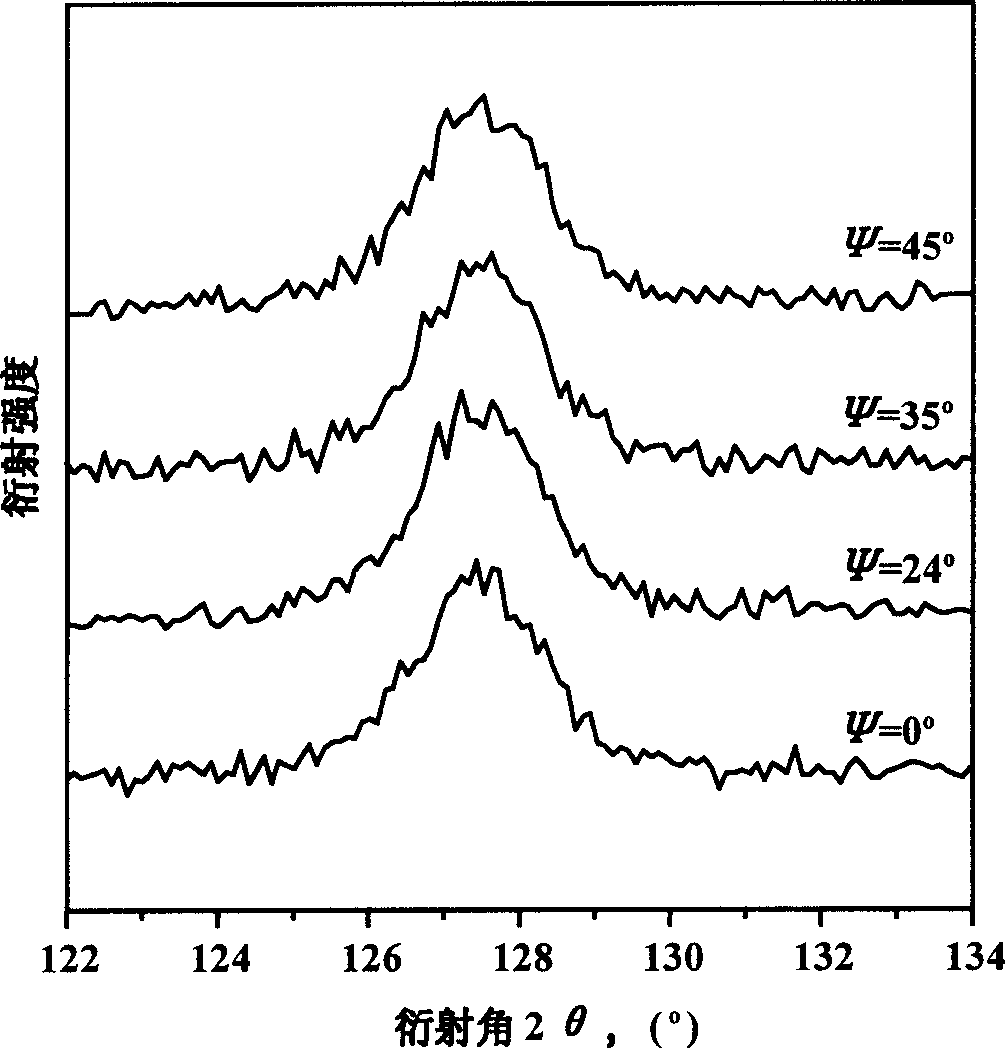

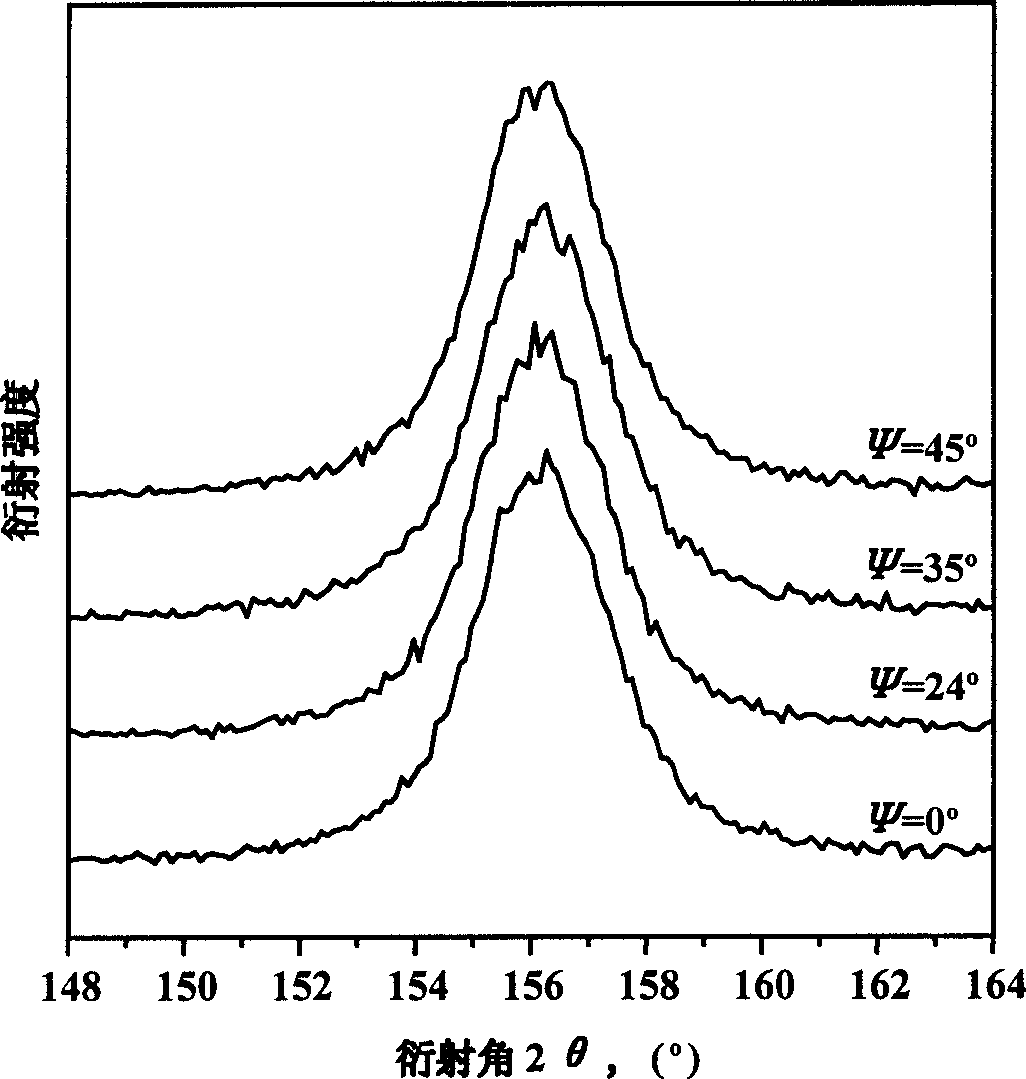

[0026] (3) Thermoforming

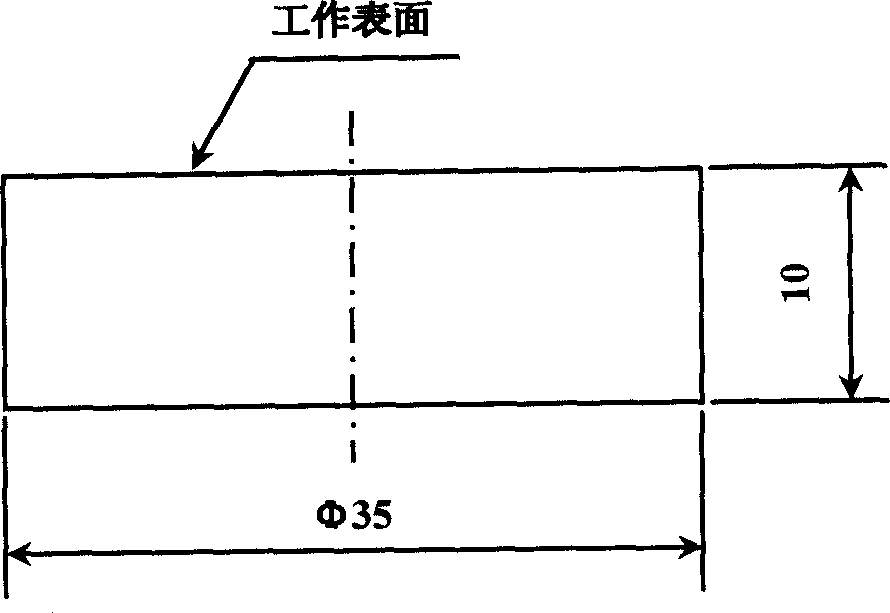

[0027] At 800°C and 10 -3 In a Pa vacuum environment, the mixed powder undergoes a hot pressing process to obtain a bulk material with a porosity of less than 3%, and the two powders are well bonded. Such as figure 1 , f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com