Environmental protection type aeration free polyurethane tyre

A polyurethane tire, inflatable technology, applied in directions with multiple inflatable chambers and no separate inflatable pads, etc., can solve the problems of left and right swinging or sliding of tires, loose steel rims, insufficient stability, etc., to reduce resources. , Good resistance to incision growth, convenient and safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

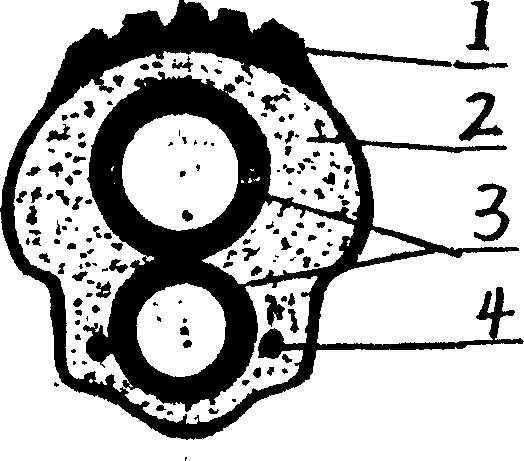

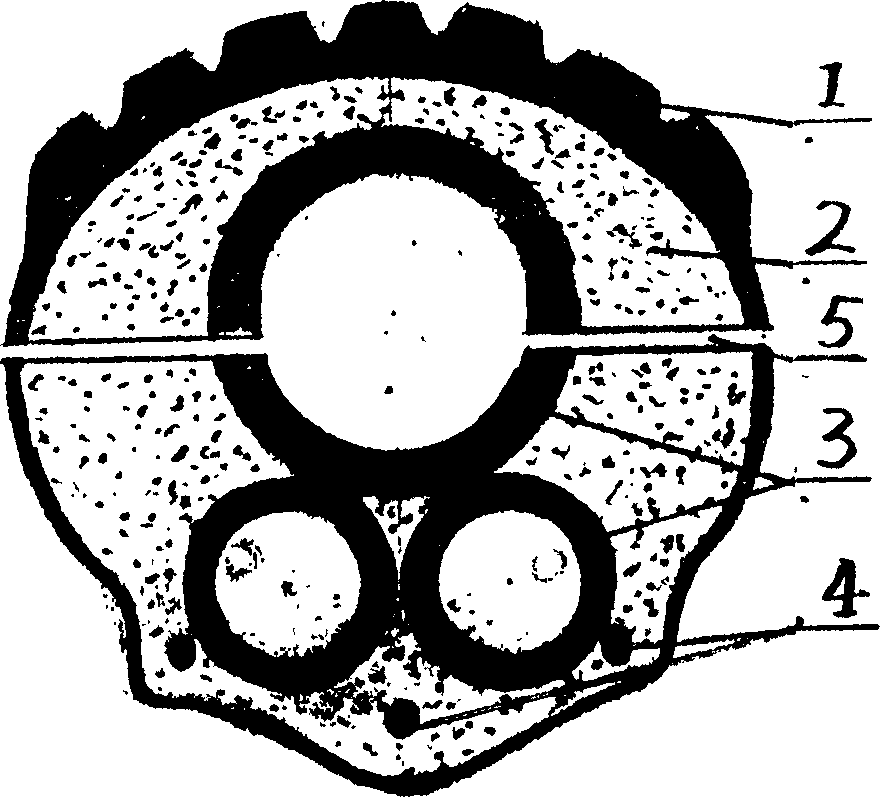

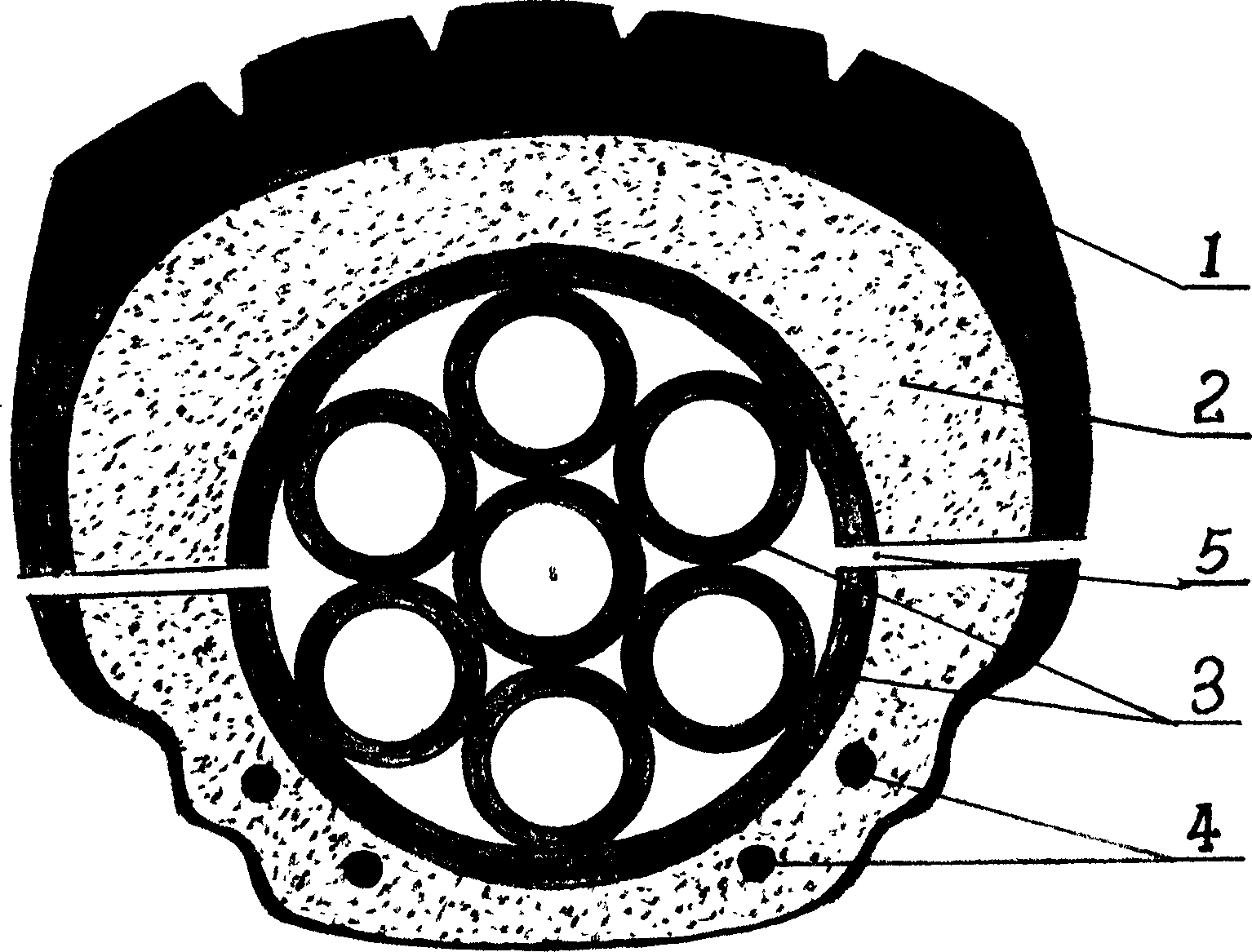

[0014] figure 1 , figure 2 , image 3 Middle mark: 1-tread, 2-carcass, 3-rubber tube, 4-fiber rope or steel wire rope, 5-radiation hole.

[0015] As shown in the figure, first take two or more high-strength fiber ropes or steel wire ropes and set them in the tire mold on the centrifugal molding machine, such as bicycle tires, children's tires, electric tires, rickshaw tires, motorcycle tires and other small tires, to set High-strength fiber ropes are suitable, forklift tires, battery tires, car tires and other large tires should be equipped with steel wire ropes, and then according to the structural design requirements of different types of tires, fix two or more pre-made rubber tubes on the tires. In the mold, close the mold, start the centrifugal molding machine, inject the prepared polyurethane liquid raw material into the centrifugal molding machine according to the designed amount, turn off the rotary switch of the centrifuge, and wait for 10-30 minutes for the tire in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com