Piping structure having leak detection function and leak detector

A leak detector and pipeline technology, which can be used in the testing of pipeline systems, machinery/structural components, and by detecting the appearance of fluid at the leak point, etc. Problems such as chemical vapor deposition equipment for a long time, to achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

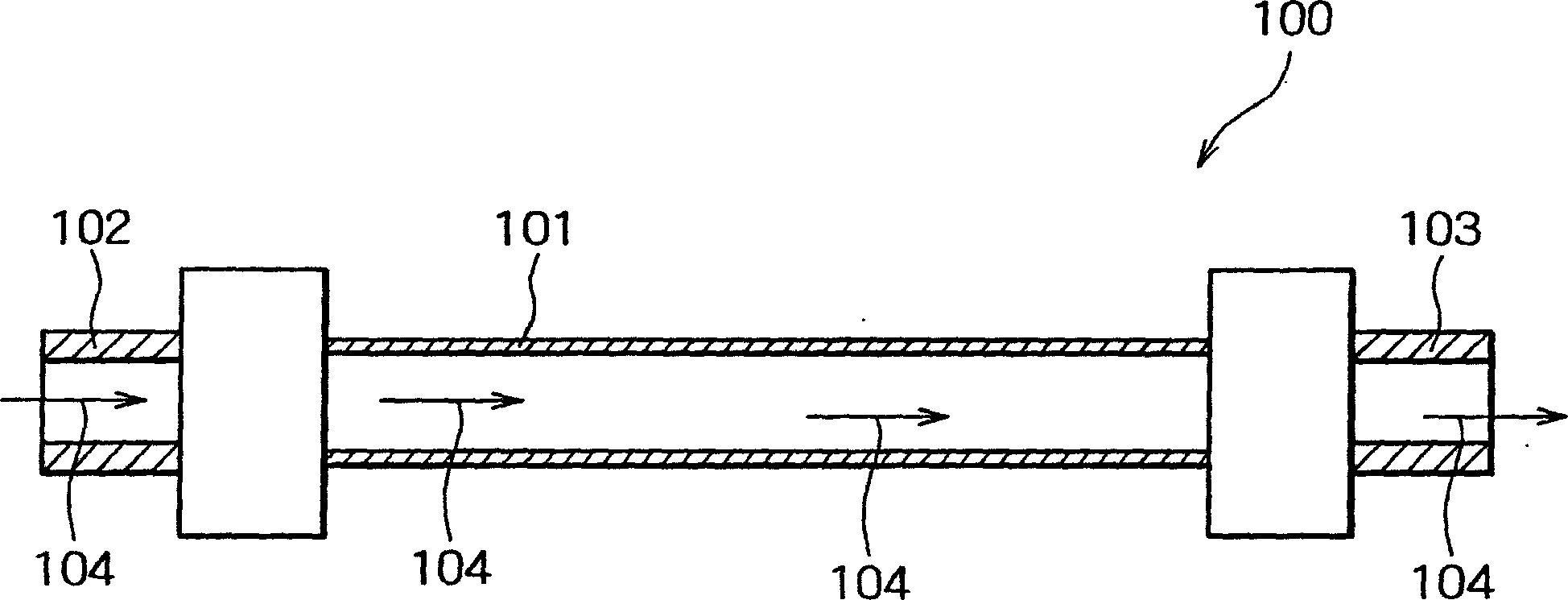

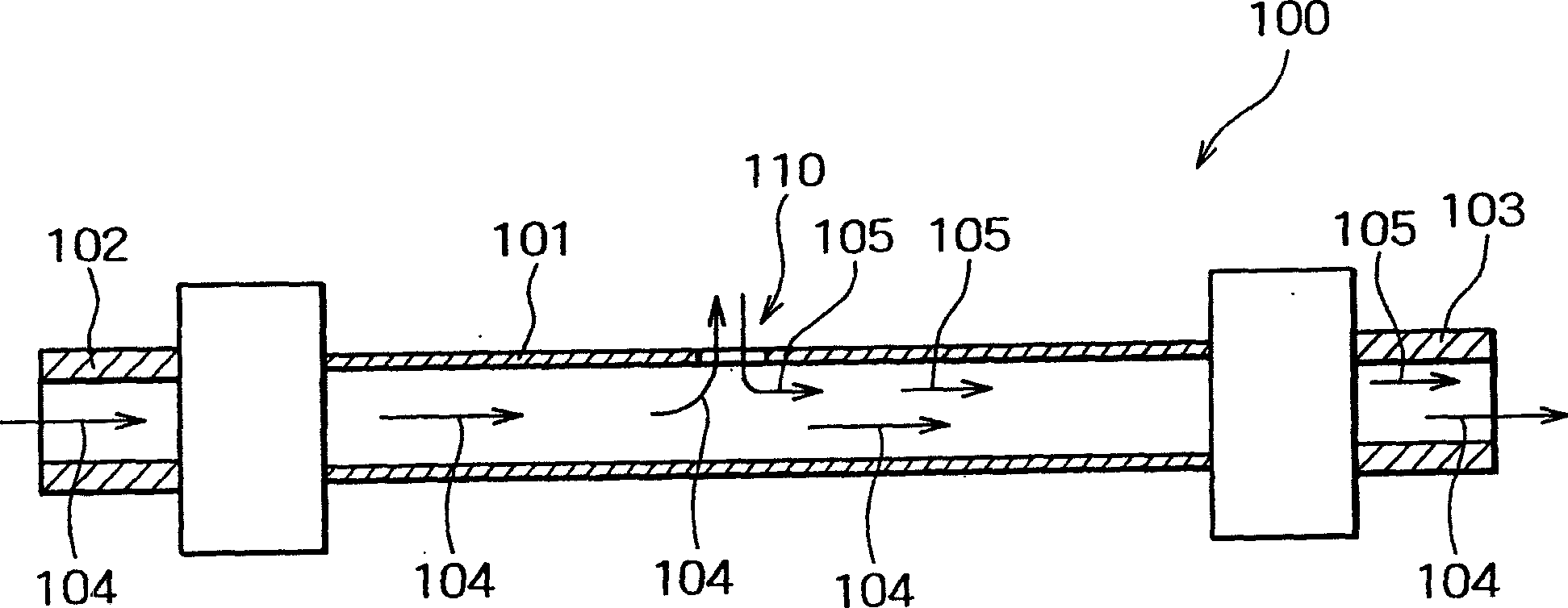

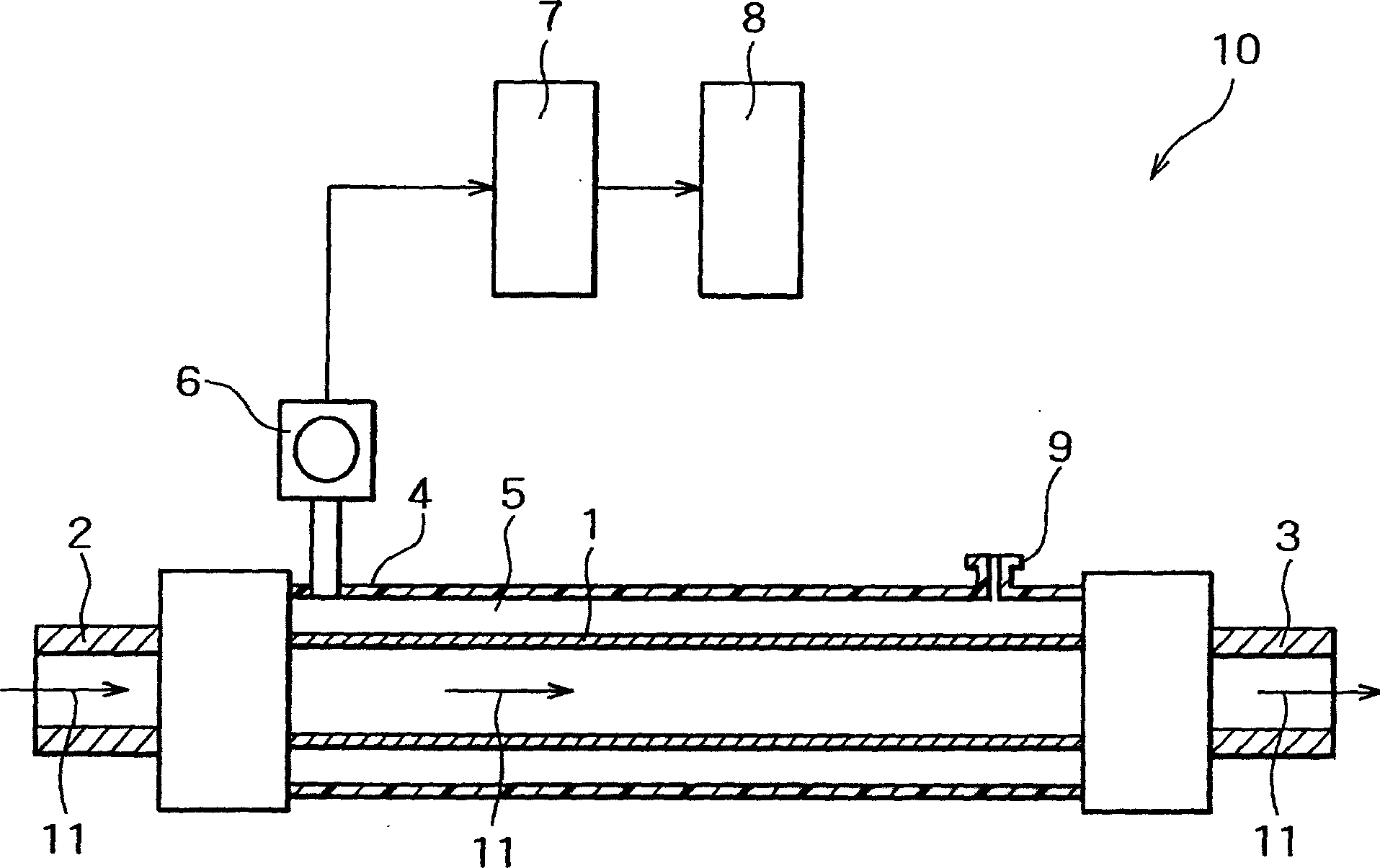

[0027] A pipeline structure with a leak detection function according to an embodiment of the present invention will now be described with reference to the accompanying drawings. image 3 is a cross-sectional side view showing the piping structure of the embodiment of the present invention. Figure 4 is shown when image 3 A cross-sectional side view of the piping structure 10 is shown in the event of a leak. Such as image 3 As shown in , in the pipeline structure 10 of this embodiment, a protective member 4 is provided to surround the flexible hose 1 for gas or liquid to flow through, and between the protective member 4 and the outer surface of the flexible hose 1 There is a specific space between. That is to say, the pipe structure 10 has a casing structure including the flexible hose 1 and the protective piece 4 . Intake pipe joints 2 and 3 such as metal gasket surface sealing devices are attached at both ends of the casing, so that a sealed space 5 is formed by the flexib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com