Tube bundle apparatus for processing corrosive fluids

A corrosive, fluid technology, applied in lighting and heating equipment, fixed catheter components, chemical/physical processes, etc., can solve problems such as increasing the operating life of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

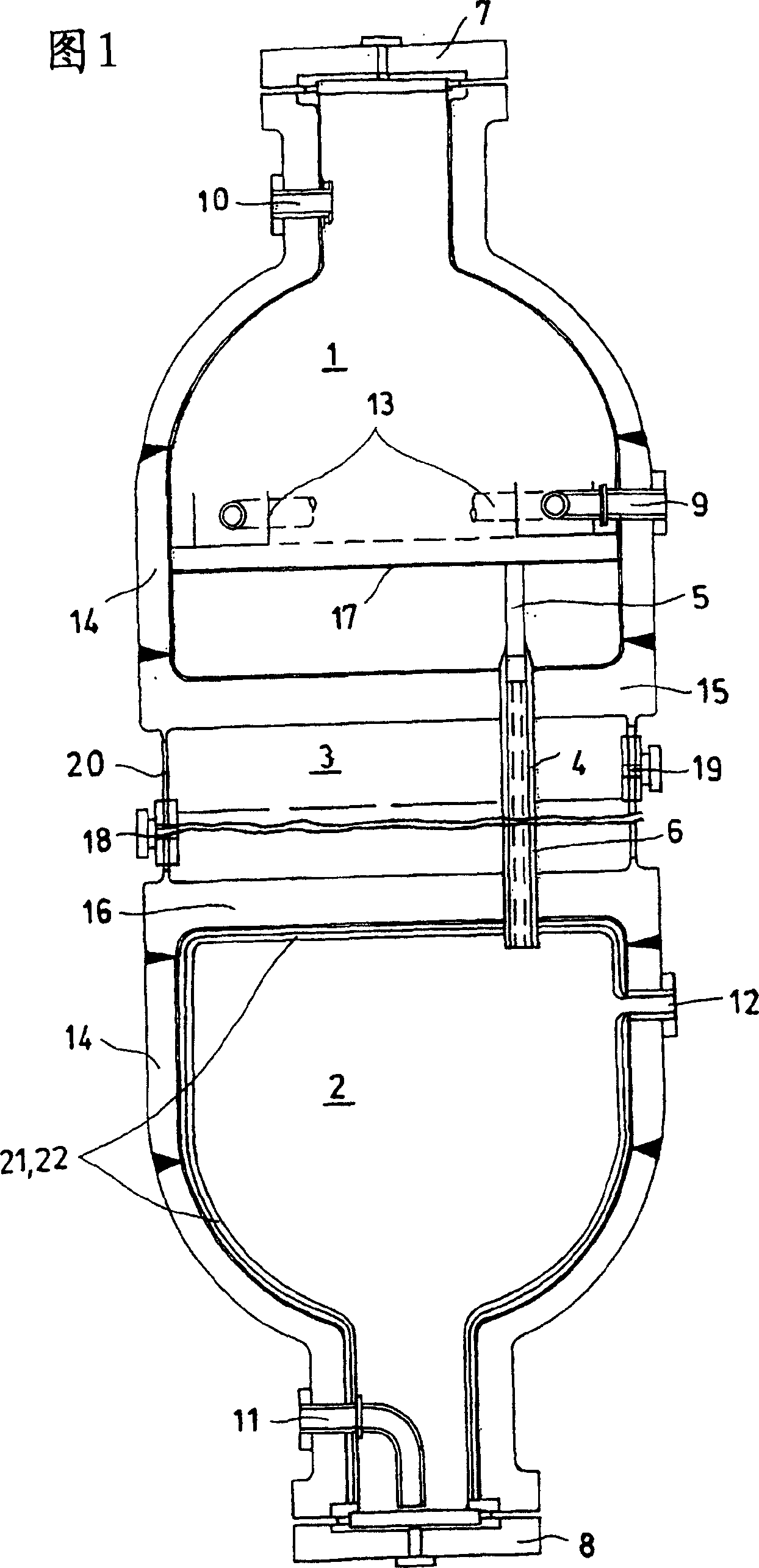

[0066] The stripping tower shown in Figure 1 is positioned vertically and basically includes three hollow parts, a hemispherical upper chamber 1, a cylindrical middle chamber 3 and a hemispherical lower chamber 2, wherein the tube bundle passes through the middle chamber 3 . The cylindrical portion has a diameter of about 1.5-2 meters and a length of about 4-6 meters. There are two manholes 7 and 8 at the upper and lower ends of the device, while chambers 1 and 2 are separated from chamber 3 by two tube sheets 15 and 16, each with 1500 to 4000 holes for discharge tube. The remainder of the side walls of the two chambers 1 and 2 are surrounded by a pressure-resistant body 14 .

[0067] The temperature of the solution from the urea synthesis reactor is about 180-200°C and the pressure is about 14-17MPa, including urea, water, excess ammonia water, and unconverted carbamate. The solution reaches the upper chamber 1 from the pipeline 9, And it is distributed using the annular c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com