Calibrated catalyst carrier body with corrugated casing and method for manufacturing the same

A shell and matrix technology, applied in the field of catalyst matrix and its manufacturing, can solve the problems of component failure and unevenness, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

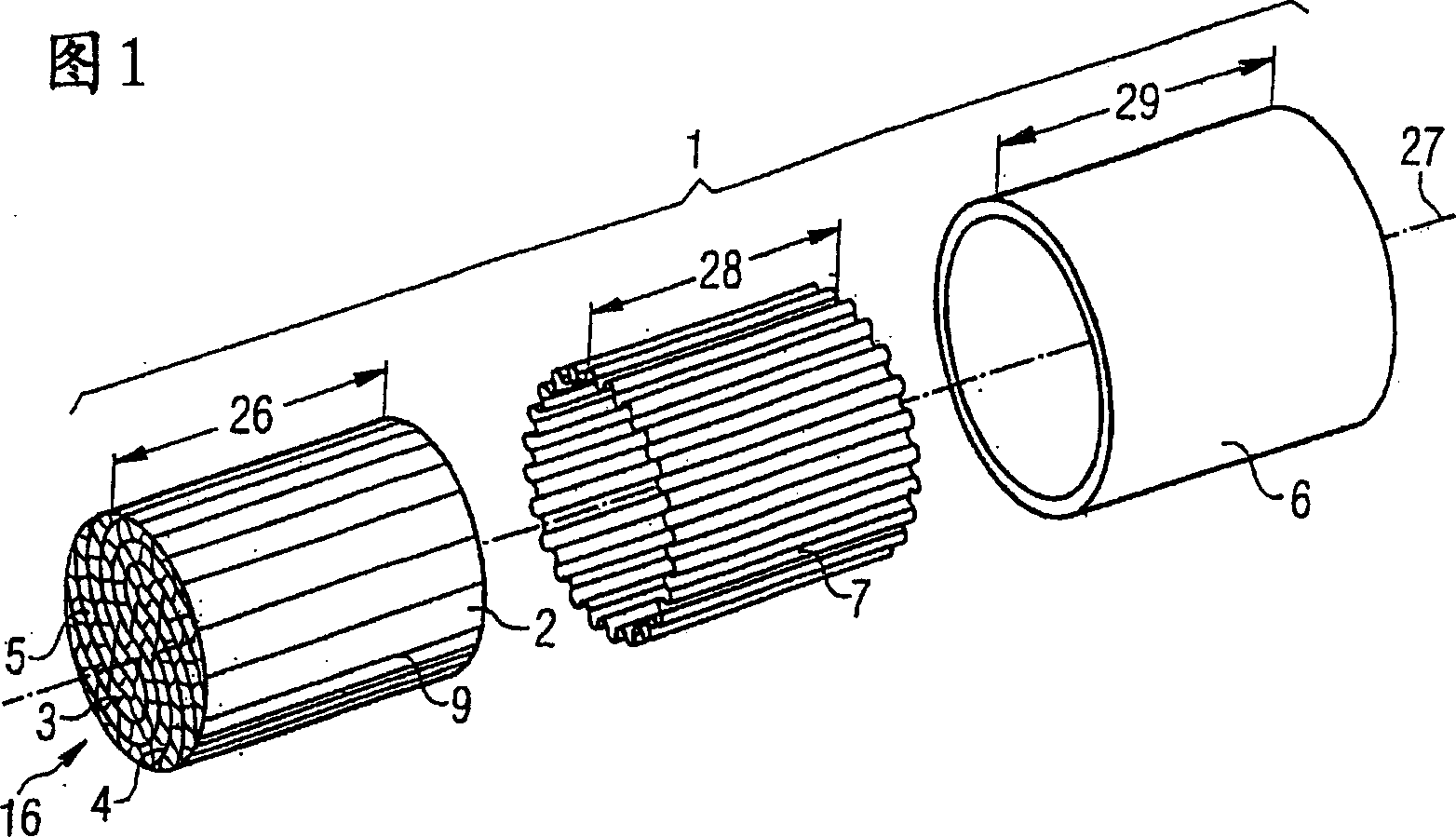

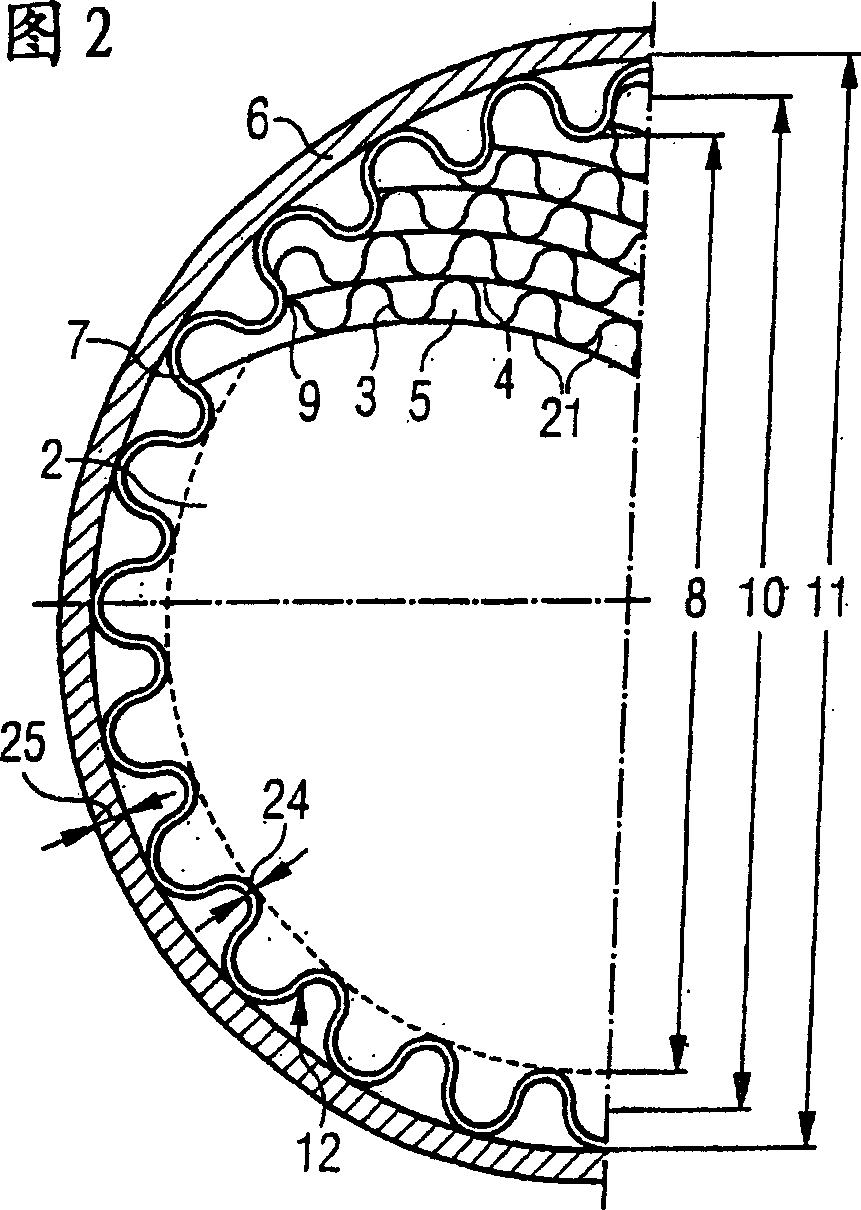

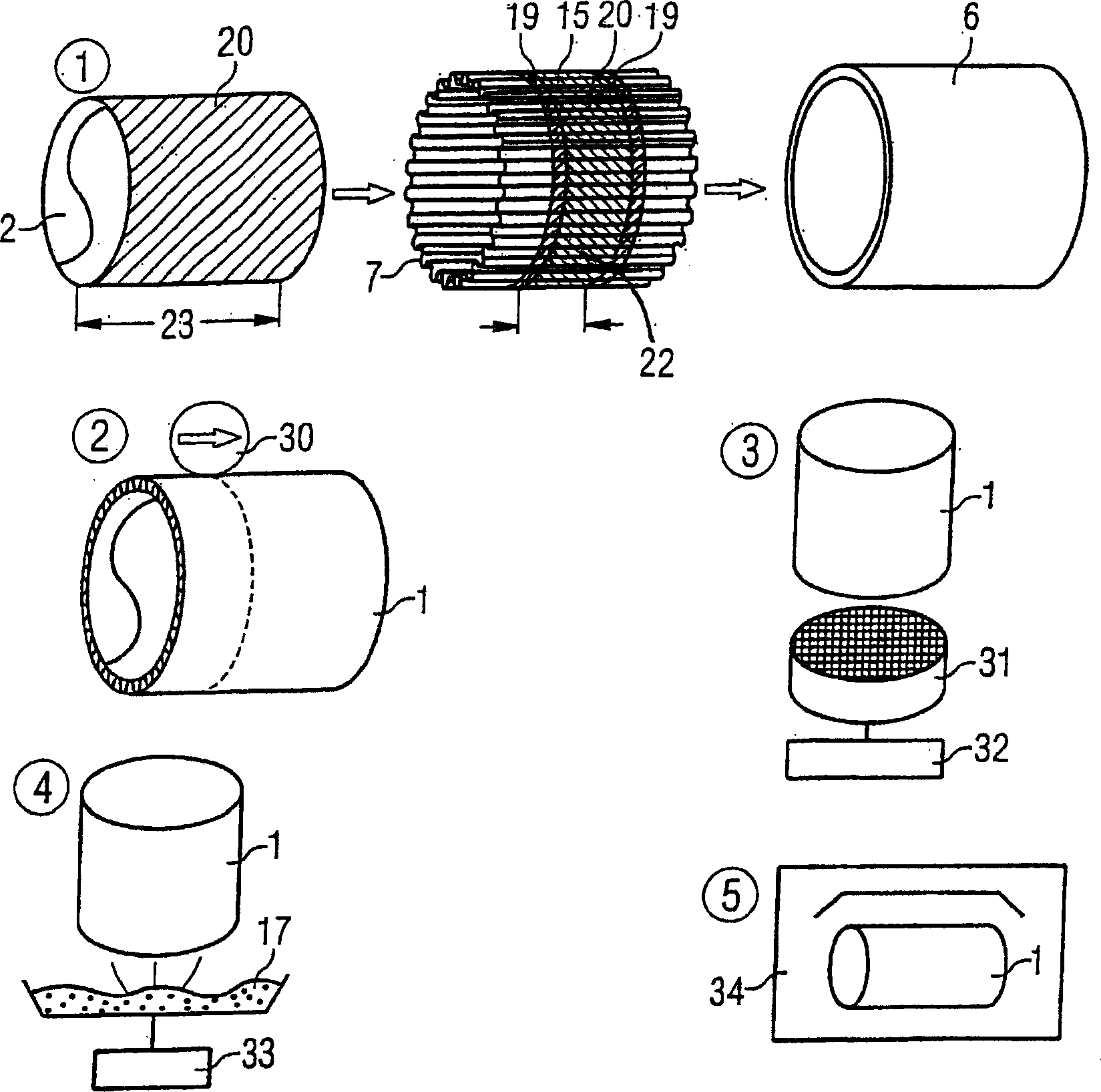

[0065] 1 shows an exploded perspective view of an embodiment of a catalytic converter base body 1 according to the invention, which comprises a honeycomb body 2 and a corrugated shell 7 arranged centrally with respect to the honeycomb body 2 or an axis 27. and a housing 6 which is also arranged centrally. Here the honeycomb body 2 is of cylindrical design, wherein the honeycomb body comprises a plurality of corrugated layers 3 and smooth layers 4 which are arranged or stacked and / or wound in such a way that their ends 9 at least partially form the design The outer periphery of the cylindrical honeycomb body 2. Due to the alternating arrangement of corrugated layers 3 and smooth layers 4 , channels 5 are formed through which exhaust gas can flow. In the illustrated embodiment of the honeycomb body 2 , the channels 5 extend from one end side 16 to the opposite end side 16 over the entire length 26 of the honeycomb body 2 , wherein the channels are designed substantially paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com