Holographic convex surface grid photo-etching light path design method

A technology of convex grating and design method, applied in optics, optical components, instruments, etc., to achieve the effect of light weight, simple structure and small spectral aberration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

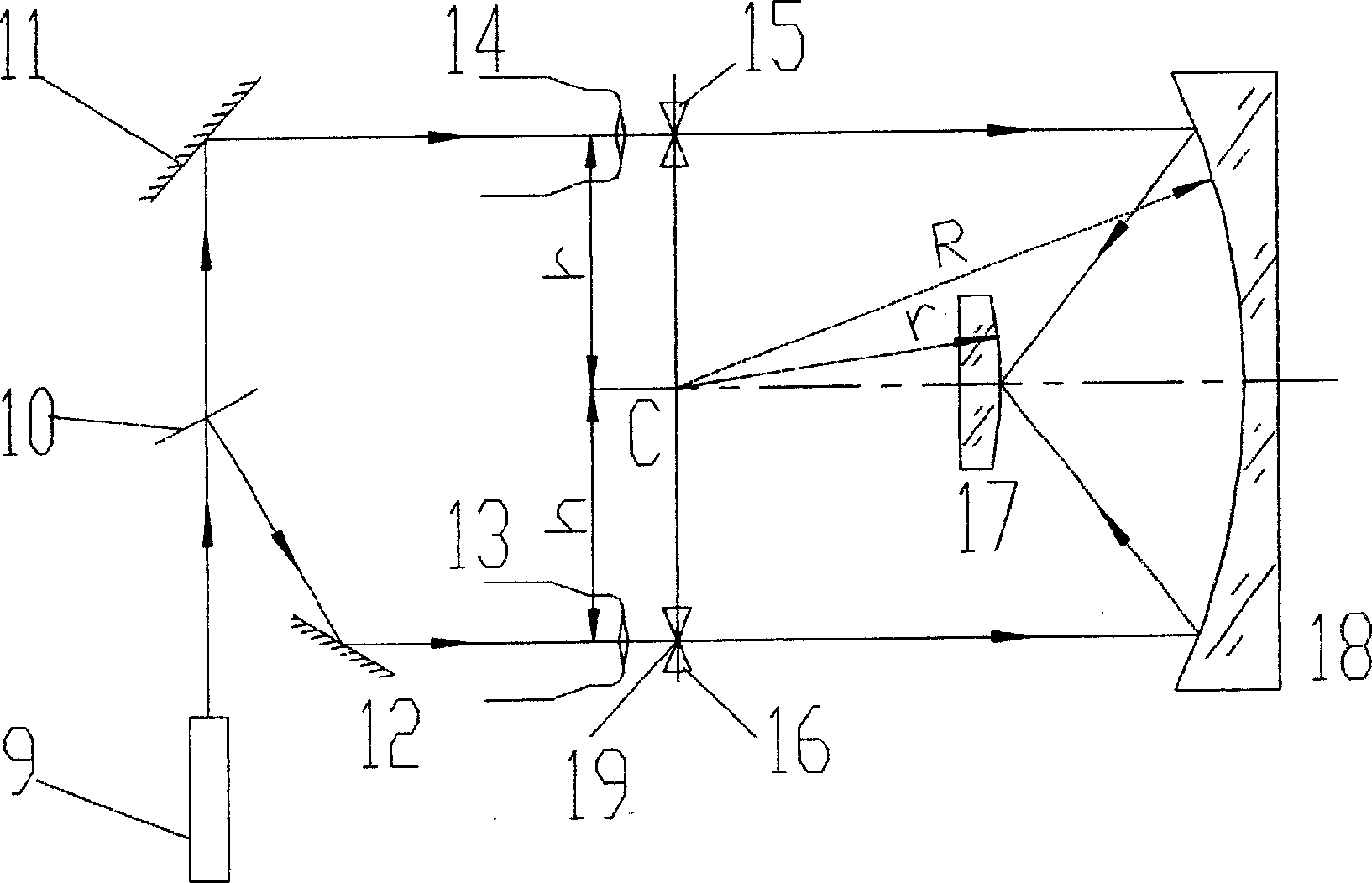

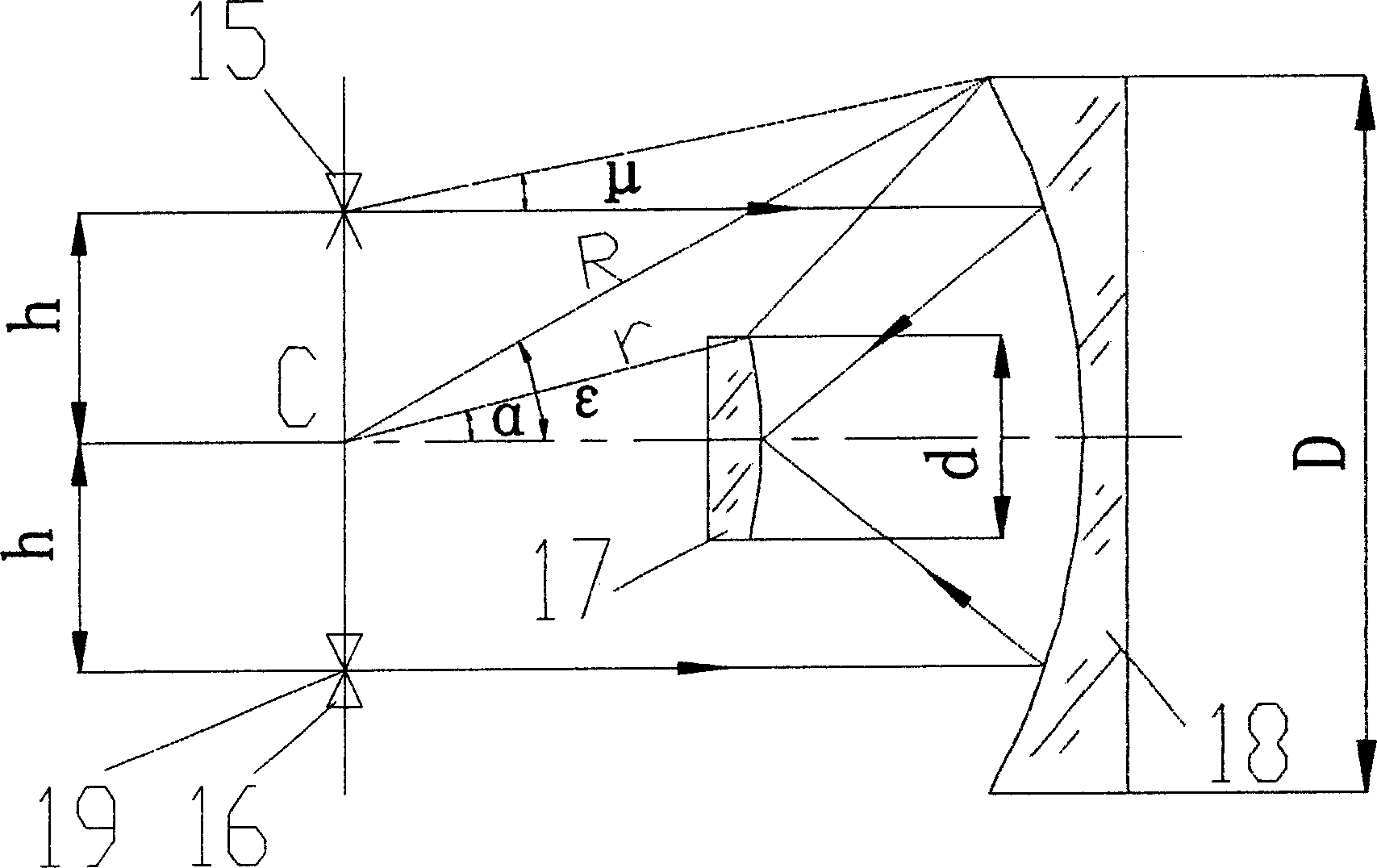

[0018] A holographic convex grating photolithography optical path design method is characterized in that it comprises the following steps, comprising: figure 2 Shown: establish a kind of concentric three-mirror optical system " no " aberration ring field photolithography optical path, it is made up of laser 9, beam splitter 10, mirror 11, 12, objective lens 13, 14, spatial filter 15, 16 , concave mirror 18, the convex grating substrate 17 is placed on the position of the convex mirror of the concentric three-mirror optical system, the laser beam emitted by the laser 9 is split into two beams by the beam splitter 10, which are divided by two mirrors 11, 12 reflects two beams parallel to each other, then injects into two objective lenses 13, 14 respectively, focuses on spatial filters 15, 16, and enters a concentric three-mirror system composed of concave mirror 18 and convex grating 17, two spatial filters Devices 15 and 16 are on the field of view of the "no" aberration ring ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap