Electric iron

A technology for electric irons and irons, applied to hand irons, washing devices, textiles and papermaking, etc., can solve problems such as no improvement, and achieve the effects of preventing burnout, reducing leakage, and preventing local overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

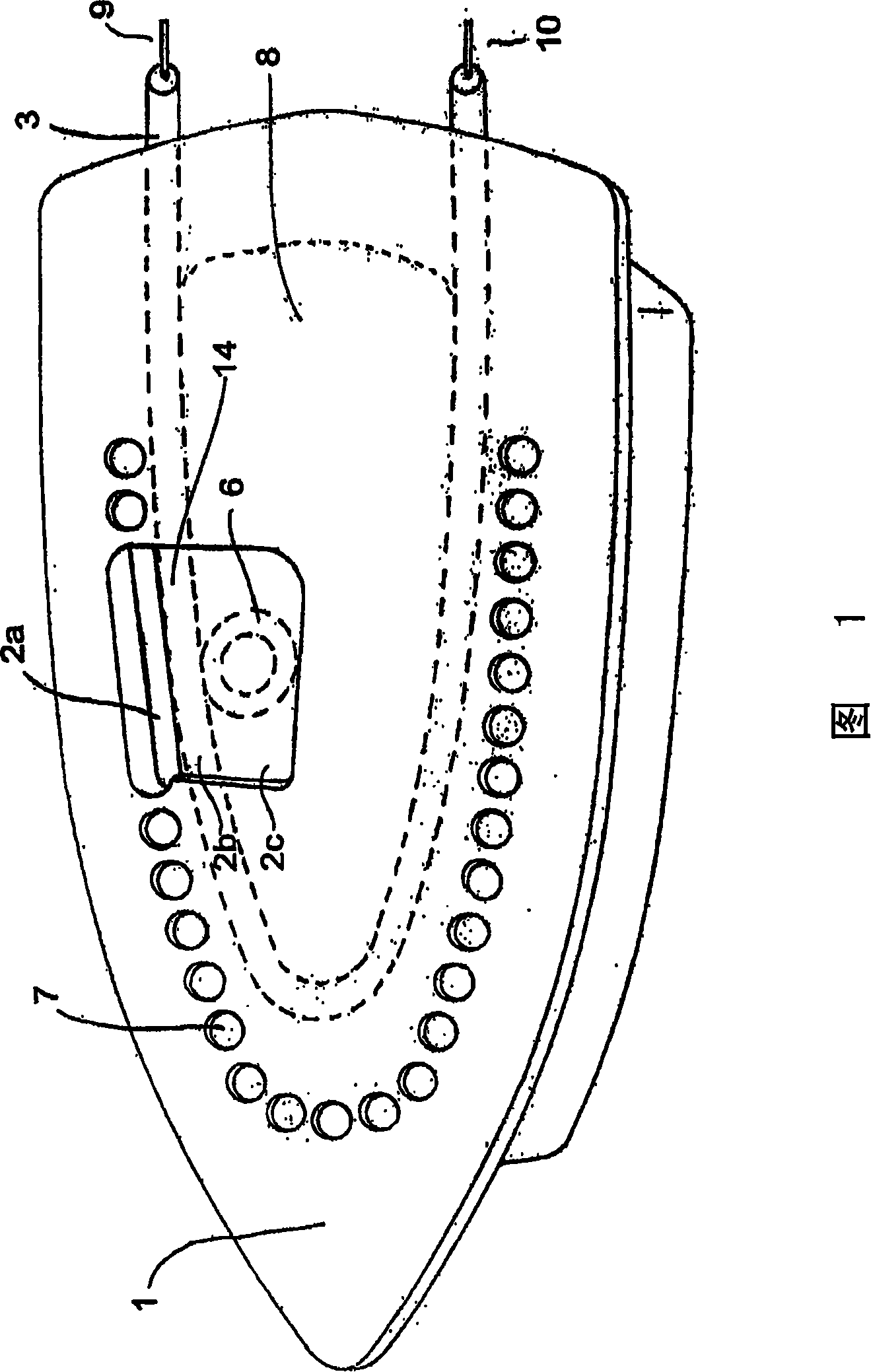

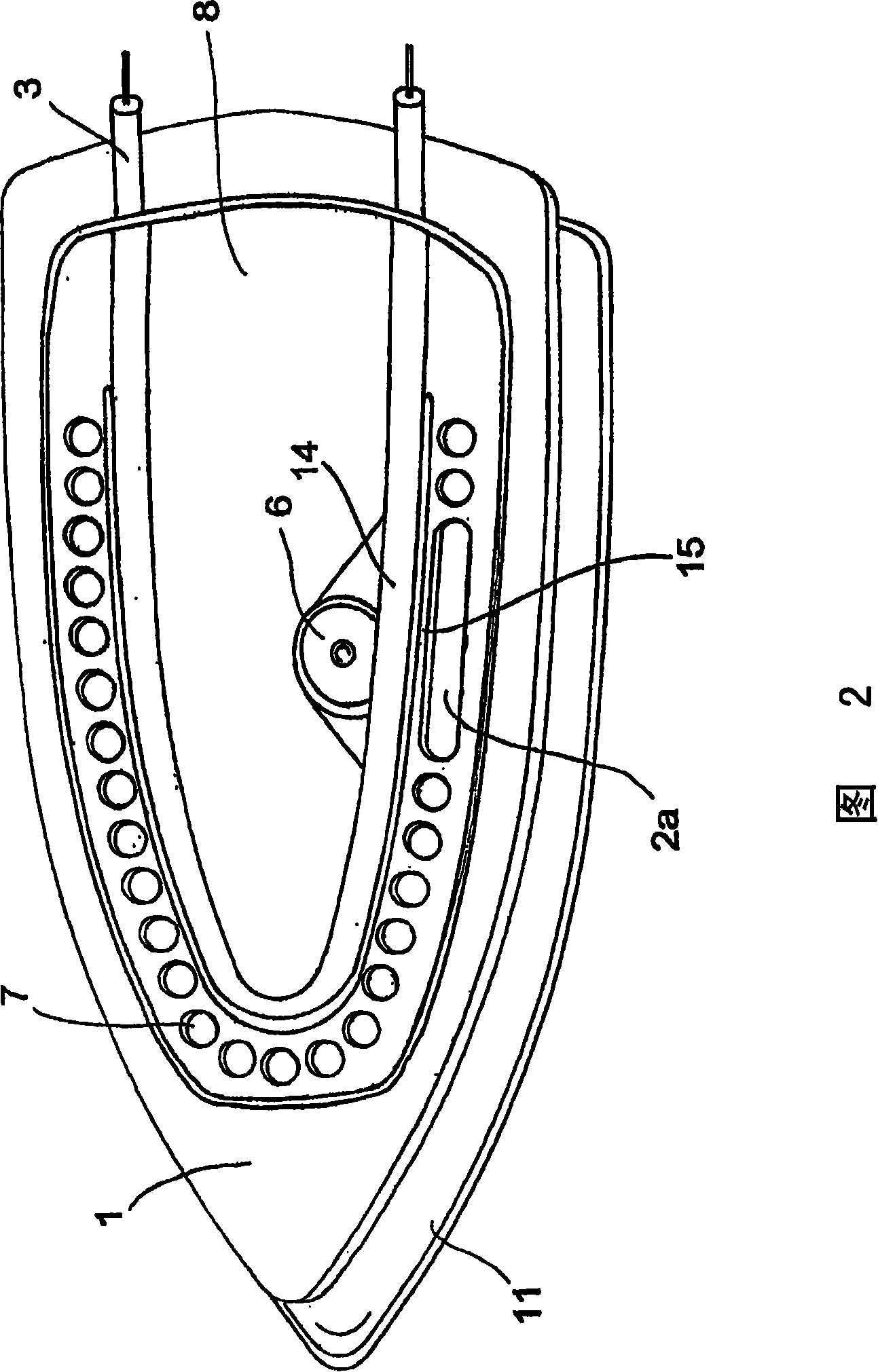

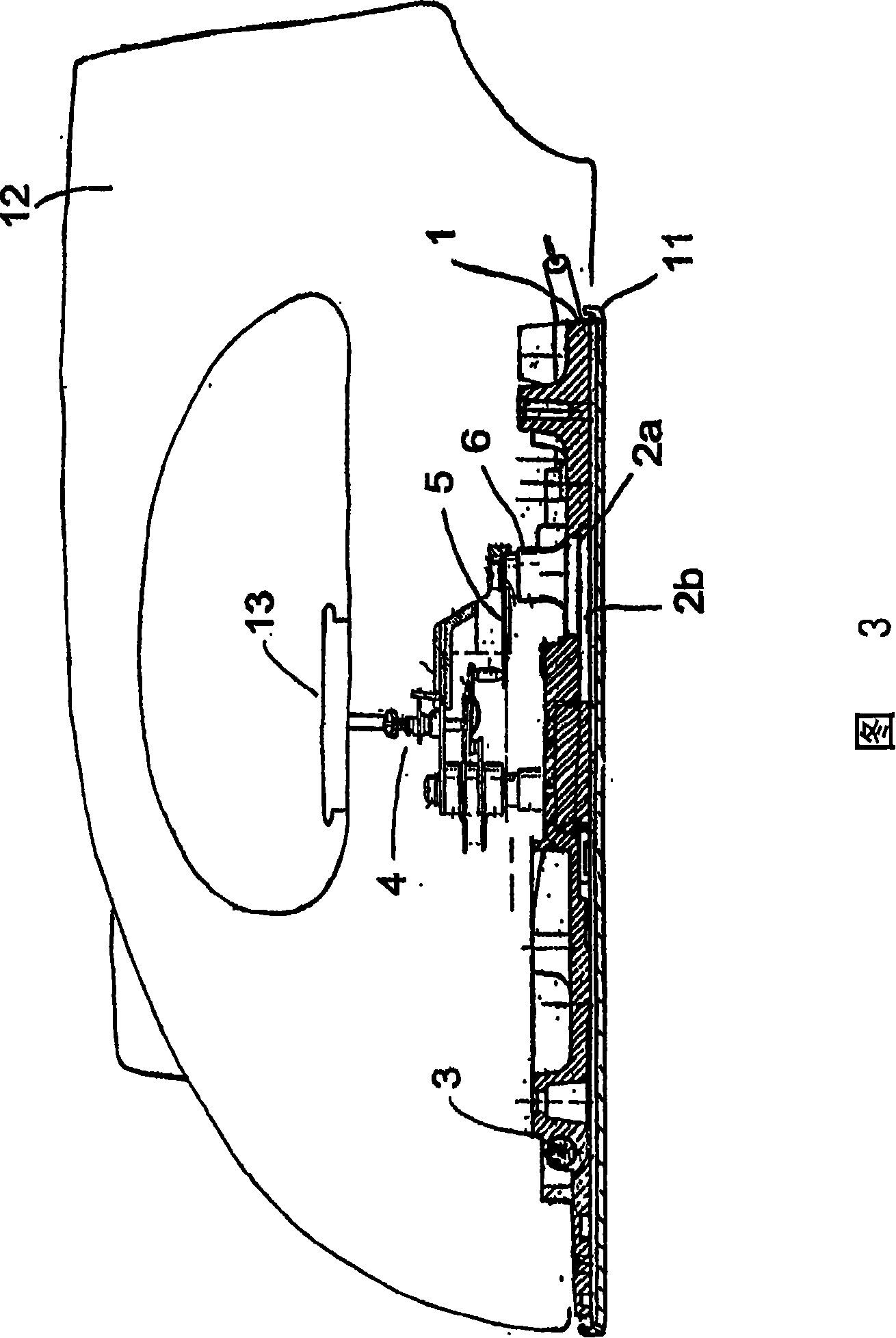

[0029] figure 1 It shows the bottom edge of the iron soleplate 1 proposed by the present invention, and a resistance heating body 3 is formed in the iron soleplate 1 manufactured by the aluminum die-casting method. The heating body 3 is U-shaped and extends along the steam escape holes 7 which connect a steam chamber 8 with the bottom edge of the iron soleplate 1. The ends 9 and 10 of the two legs of the U-shaped heating body 3 protrude from the steam chamber 8 and have electrical contacts.

[0030] Below the steam chamber 8, a dome-shaped contact point 6 is cast on the soleplate 1 of the iron. The contact point 6 forms a tube seat, and the temperature probe 5 of a regulating device 4 contacts the tube seat. The dome-shaped contact point 6 directly adjoins the heating body section 14 of one leg of the U-shaped heating body 3. The dome-shaped contact point 6 is raised on the upper edge of the soleplate 1 of the iron. Below the dome-shaped contact point 6, there is a gap space 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com