Circulating pump real time quantity regulation and control system

A circulating water pump and control system technology, applied in the control/regulation system, non-electric variable control, temperature control, etc., can solve the problems of waste of heat energy, failure to achieve timely and effective adjustment effects, increase power consumption, etc., to improve The quality of heating, the effect of saving electricity is remarkable, and the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

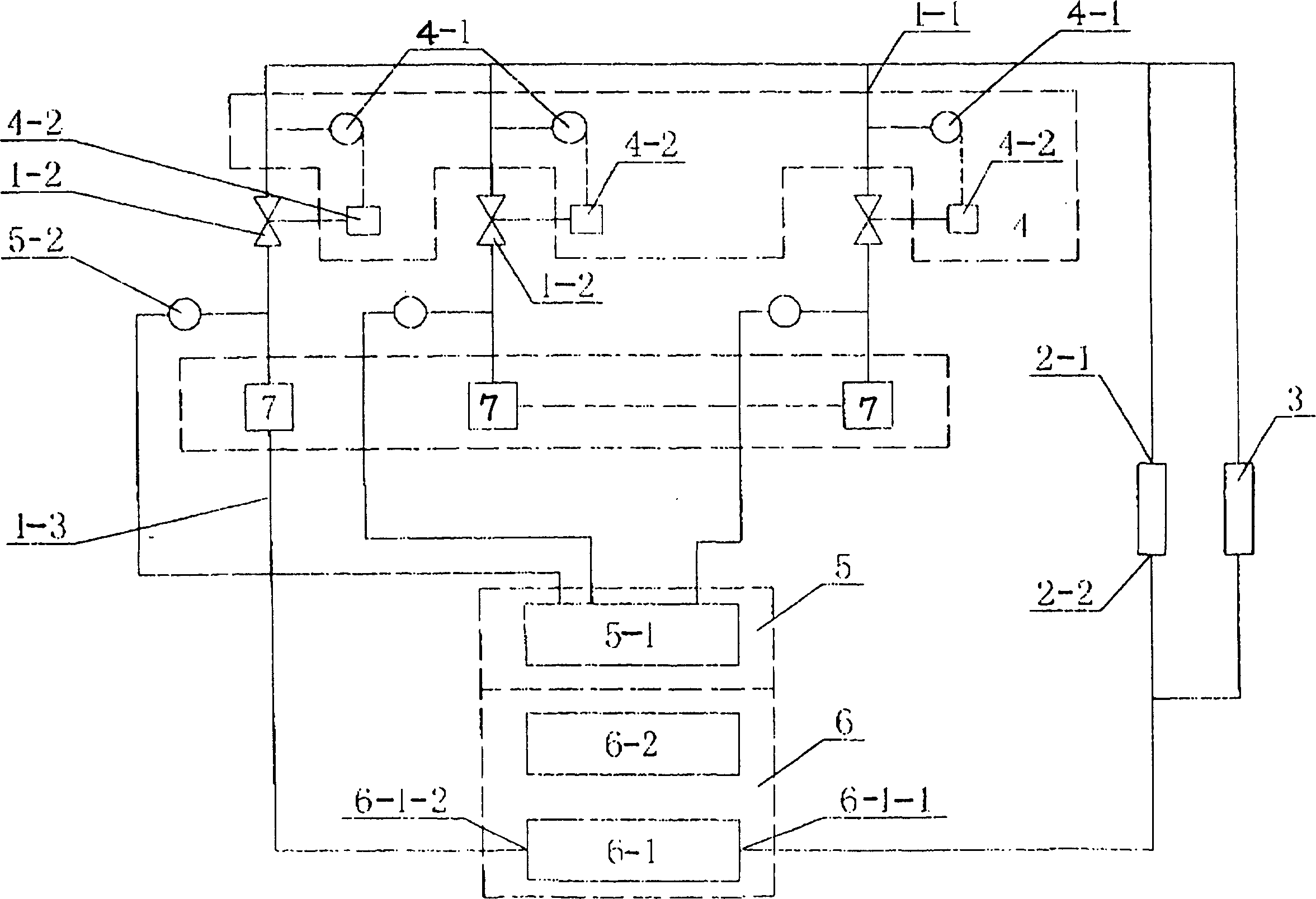

[0017] The basic principle of this system is: eliminate human factors, automatically control the boiler outlet water temperature to its rated working temperature, ensure the maximum temperature difference between the supply and return water of the boiler, and minimize the flow rate when delivering the same amount of heat. The frequency conversion speed regulating device will save the electric energy reduced by reducing the flow.

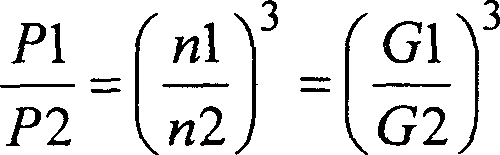

[0018] The core theory of saving electricity of the present invention is: "the power similarity law of centrifugal water pump":

[0019] lambda N =λ ρ ·λ n 3 ·λ L 5

[0020] That is: the power similarity coefficient λ of the pump N Density similarity coefficient λ to the fluid ρ , the third power λ of the speed similarity coefficient n 3 , the fifth power λ of the impeller geometric similarity coefficient L 5 Proportional.

[0021] When the physical parameters of the fluid delivered by the pump are constant and the geomet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com