Mechanism for automatic coating removing, blanking and diverse stirring and control device therefor

A control device, a variety of technologies, applied in mixer accessories, mixers, chemical instruments and methods, etc., can solve problems such as being unsuitable for personal use at home, high difficulty, complex technology, etc., to achieve simple and reliable electrical connection, and ensure accuracy. , the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

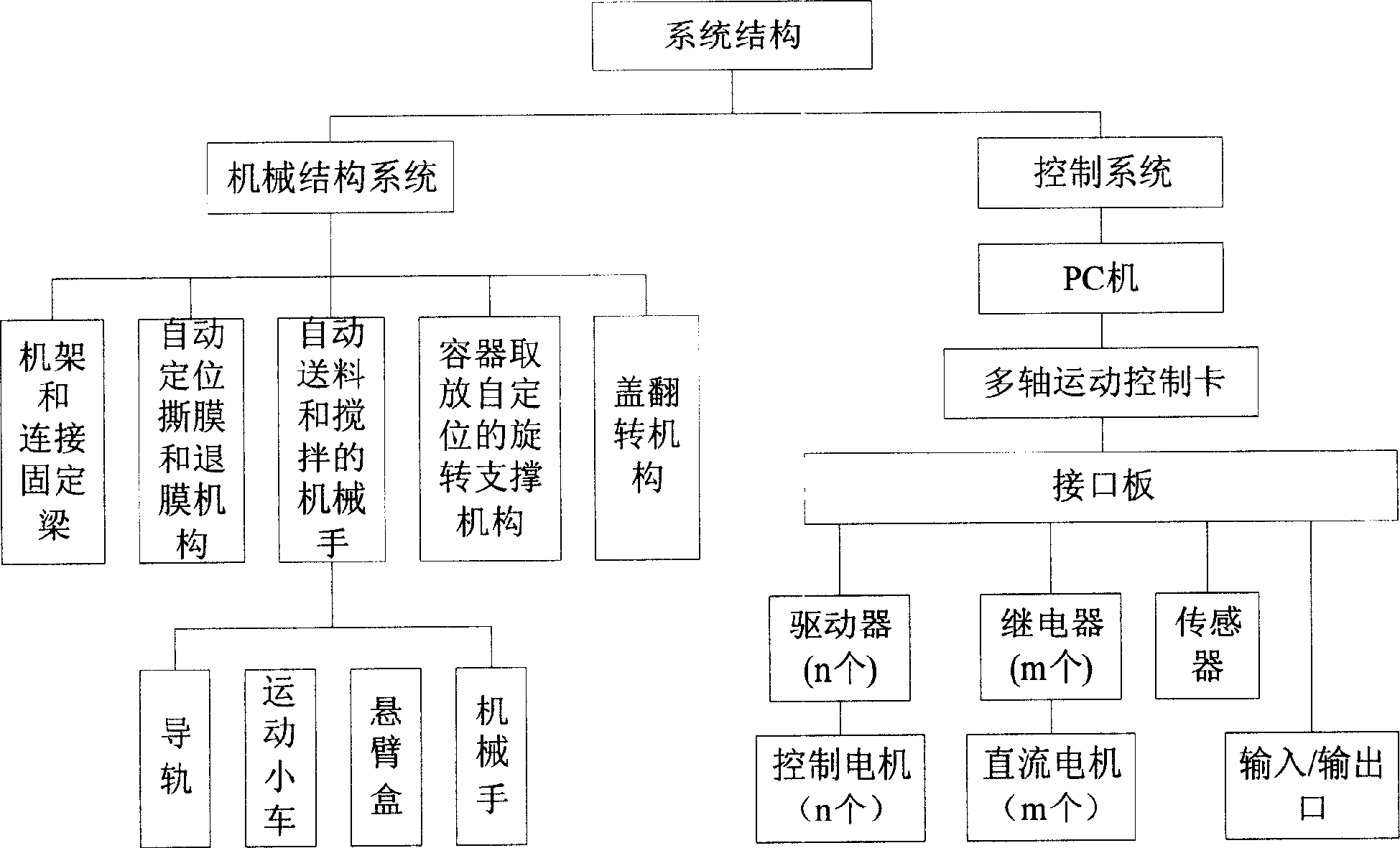

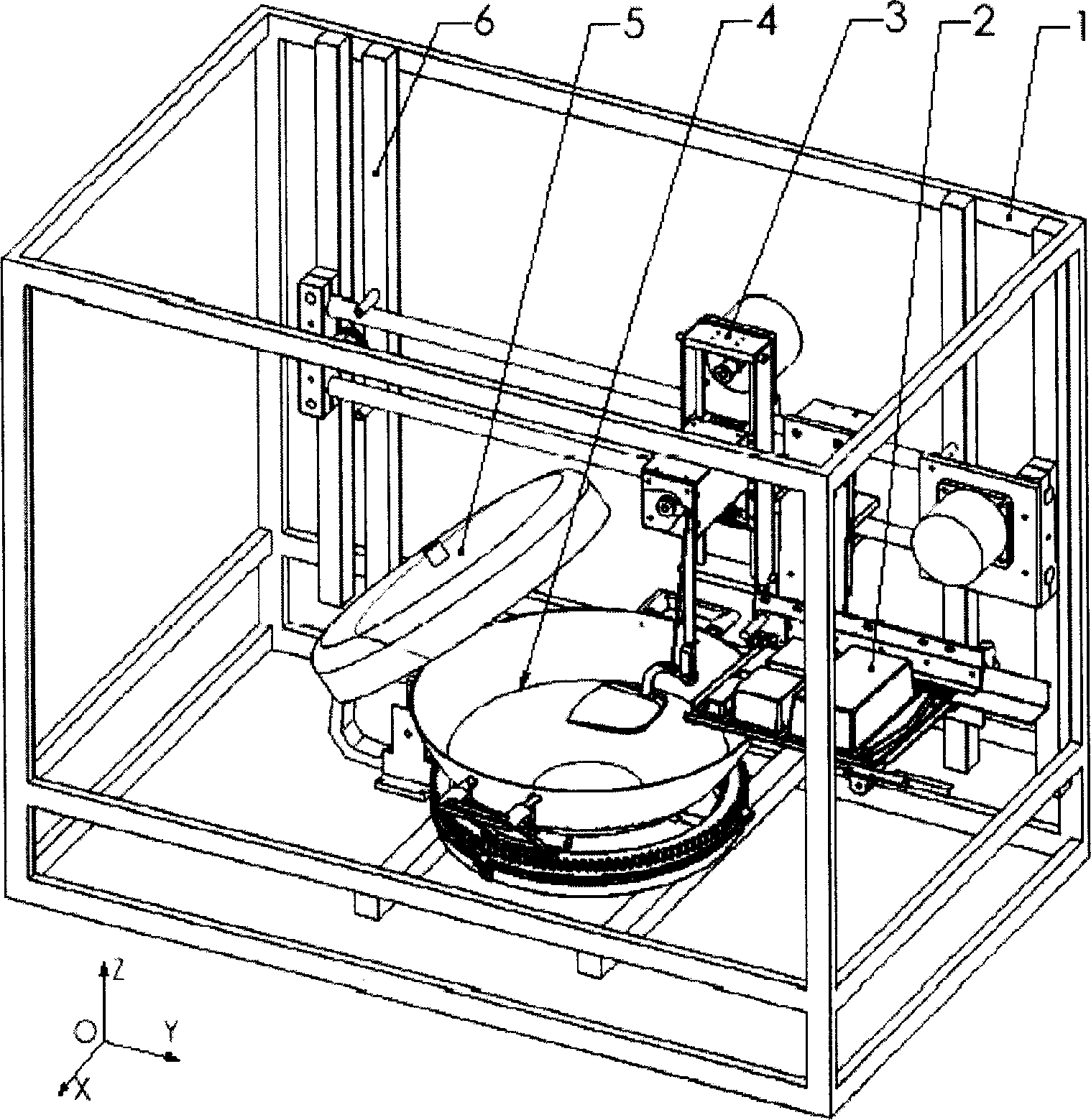

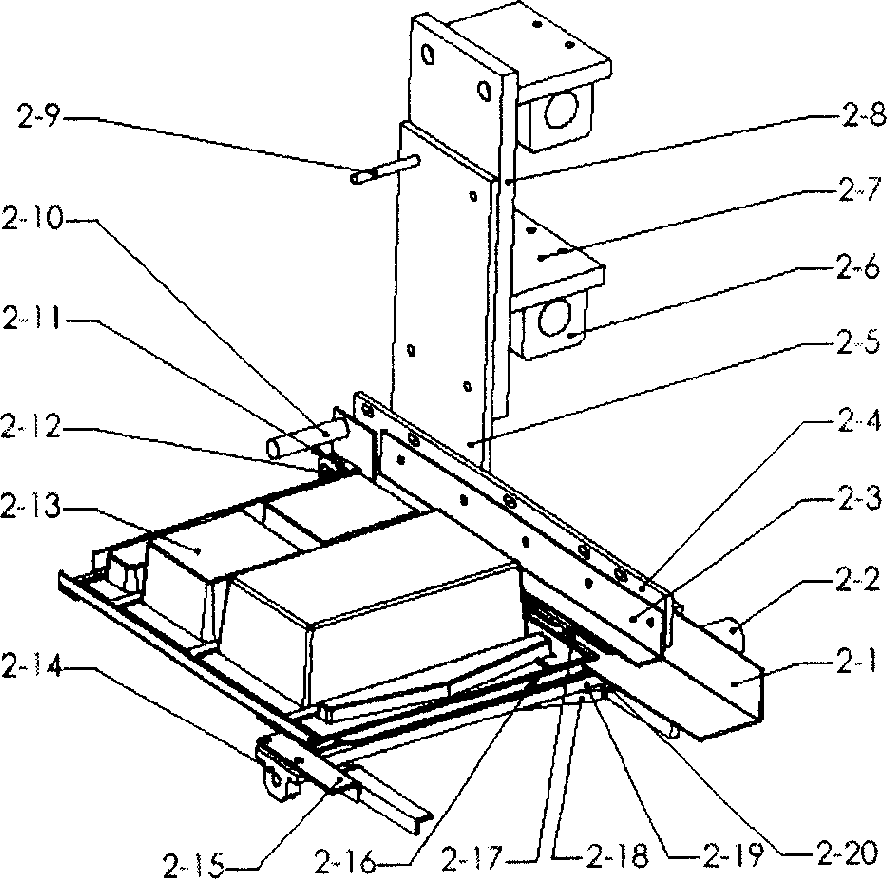

[0019] see figure 1 , 2shown. The technical solution adopted by the present invention to solve the technical problem is: the overall system is composed of a mechanical structure system and a control system. The mechanical structure is mainly composed of frame 1, automatic positioning film tearing and film removal mechanism 2, automatic feeding and stirring manipulator 3, container picking and placing self-positioning rotating support mechanism 4, cover turning mechanism 5 and connecting fixed beam 6; the frame 1. It is used for the installation and fixing of the whole system. The connecting and fixing beam 6 is fixed on the frame 1 by welding or screws, and the automatic feeding and stirring manipulator 3 is connected with the connecting and fixing beam through the positioning installation block 3-1-1 of the guide rail 3-1 The connection of 6 makes it connected with the frame 1 as a whole; the rotating support mechanism 4 and the cover turning mechanism 5 for taking and plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com